Mastering Master Mixes: A 2025 Guide to Optimized PCR for Biomedical Assays

This article provides a comprehensive guide for researchers and drug development professionals on optimizing PCR master mixes to enhance the accuracy, efficiency, and reliability of biomedical assays.

Mastering Master Mixes: A 2025 Guide to Optimized PCR for Biomedical Assays

Abstract

This article provides a comprehensive guide for researchers and drug development professionals on optimizing PCR master mixes to enhance the accuracy, efficiency, and reliability of biomedical assays. Covering foundational principles to advanced applications, it explores the selection of high-fidelity and hot-start polymerases, formulation for complex templates, and integration with cutting-edge multiplexing and digital PCR technologies. A strong focus is placed on systematic troubleshooting for common pitfalls like nonspecific amplification and low yield, alongside rigorous validation strategies to ensure data integrity for clinical and research applications. The guidance synthesizes current market trends and proven methodologies to empower scientists in achieving robust, reproducible molecular diagnostics and research outcomes.

The Core Components: Understanding Master Mix Chemistry and Selection Criteria

Core Components of a PCR Master Mix

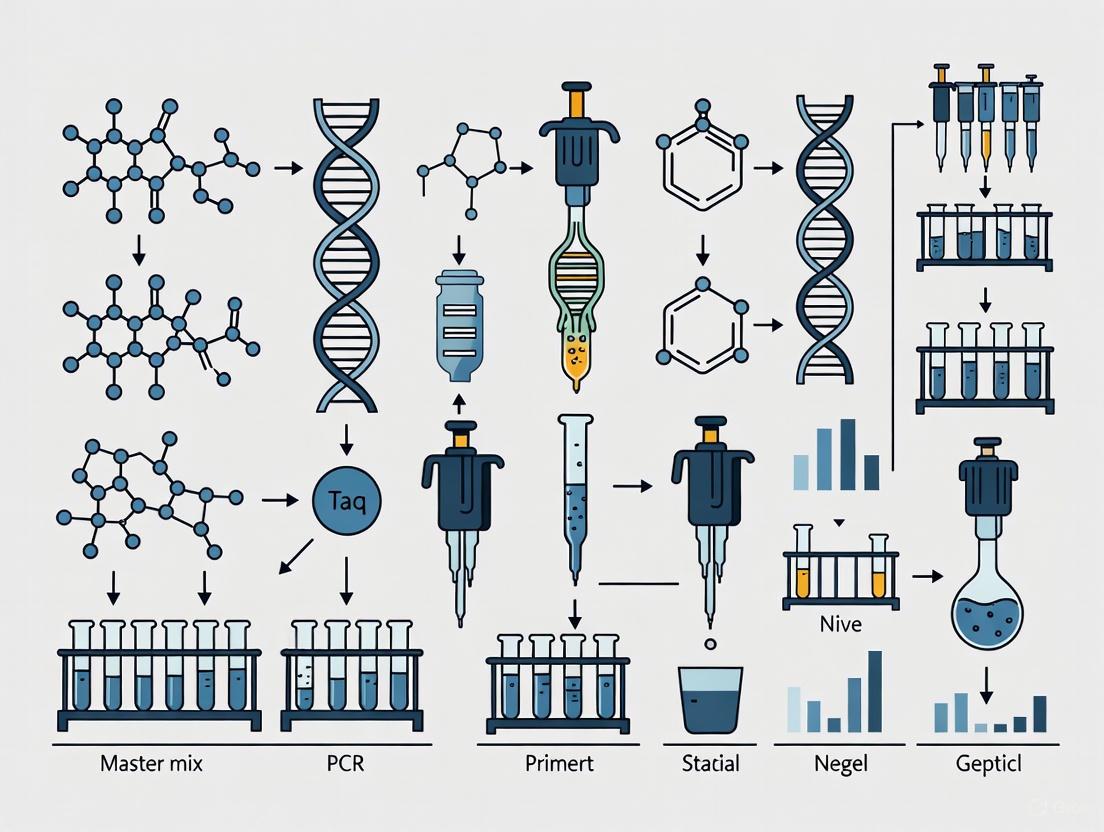

A PCR master mix is a pre-formulated, ready-to-use solution that contains all the essential components required for the polymerase chain reaction, except for the template DNA and gene-specific primers [1]. Its use standardizes workflow, minimizes pipetting errors, and ensures experimental consistency. The table below summarizes the core components and their critical functions in DNA amplification.

Table 1: Essential Components of a Standard PCR Master Mix

| Component | Primary Function | Standard Final Concentration |

|---|---|---|

| DNA Polymerase | Enzyme that synthesizes new DNA strands by adding nucleotides to the primer. | 1–2 units per 50 µL reaction [2] |

| dNTPs | Deoxynucleoside triphosphates (dATP, dCTP, dGTP, dTTP); the building blocks for new DNA strands. | 0.2 mM of each dNTP [2] |

| MgCl₂ | Essential cofactor for DNA polymerase activity; stabilizes DNA and primer-template interactions. | 1–5 mM (often 1.5–2.0 mM) [3] [4] |

| Buffer System | Maintains optimal pH and ionic conditions (e.g., Tris-HCl, KCl) for enzyme activity and specificity. | 1x concentration [1] |

DNA Polymerase

DNA polymerases, such as the ubiquitous Taq polymerase, are enzymes that catalyze the template-directed synthesis of new DNA strands. They add deoxynucleotides to the 3'-end of a primer that is annealed to the target sequence. In a typical 50 µL reaction, 1–2 units of enzyme are sufficient. However, this amount may require optimization, as higher concentrations can lead to nonspecific amplification, while lower concentrations may result in poor yield [2].

Deoxynucleoside Triphosphates (dNTPs)

dNTPs provide the necessary nucleotides for the DNA polymerase to incorporate into the newly synthesized strand. The four dNTPs are typically added in equimolar concentrations to ensure balanced base incorporation. The recommended final concentration for each dNTP is generally 0.2 mM [2]. It is crucial to maintain free dNTP concentrations above the enzyme's Km (approximately 0.010–0.015 mM) for efficient incorporation. Excessively high dNTP concentrations can be inhibitory, as they can chelate Mg²⁺ ions, making them unavailable for the polymerase [2].

Magnesium Ion (Mg²⁺)

Magnesium chloride (MgCl₂) is a critical component because the Mg²⁺ ion is an essential cofactor for DNA polymerase activity [3] [4]. It facilitates the formation of the phosphodiester bond between the 3'-OH of the primer and the phosphate group of the incoming dNTP. Furthermore, Mg²⁺ stabilizes the interaction between the primer and the template DNA by neutralizing the negative charges on their phosphate backbones [4]. The optimal concentration is typically between 1 mM and 5 mM, with 2 mM being a common starting point [3] [4]. The precise concentration must be optimized, as it is influenced by dNTP and DNA template concentrations.

Buffer System

The buffer provides a stable chemical environment for the PCR. It typically contains Tris-HCl to maintain a consistent pH (usually around 8.0–8.5) and potassium chloride (KCl) to promote primer annealing. The buffer is the foundation that ensures all other components function together correctly [1].

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Key Reagents for Master Mix Preparation and PCR Optimization

| Reagent / Solution | Function | Key Considerations |

|---|---|---|

| 2x Concentrated Master Mix | Pre-mixed solution of all core components; simplifies setup and enhances reproducibility [1]. | Allows equal-volume addition of master mix and sample/primer combo. Ideal for high-throughput applications. |

| Hot-Start DNA Polymerase | Enzyme engineered to be inactive at room temperature. | Reduces nonspecific amplification and primer-dimer formation prior to the initial denaturation step. |

| MgCl₂ Stock Solution (e.g., 25 mM) | Separate magnesium source for reaction optimization [3]. | Essential for fine-tuning Mg²⁺ concentration, which is critical for assay specificity and efficiency. |

| PCR Enhancers / Stabilizers | Additives like DMSO, BSA, or betaine. | Can improve amplification efficiency of difficult templates (e.g., those with high GC content). |

| UDG (Uracil-DNA Glycosylase) | Enzyme used in carryover prevention protocols. | Degrades PCR products from previous reactions (containing dUTP) before amplification, preventing contamination [2]. |

Troubleshooting Guides & FAQs

Frequently Asked Questions

Q1: Why is magnesium concentration so critical, and how do I optimize it? Magnesium is a required cofactor for thermostable DNA polymerases. Without adequate free Mg²⁺, the enzyme is inactive. Conversely, excess free Mg²⁺ reduces enzyme fidelity and increases nonspecific amplification [3]. Optimization is required because the amount of free Mg²⁺ is affected by the concentration of dNTPs, chelating agents (like EDTA), and the DNA template itself [3]. A standard optimization protocol involves a magnesium titration using a separate MgCl₂ stock solution, testing a range from 1.0 mM to 3.0 mM in 0.5 mM increments.

Q2: My positive control amplifies, but my sample does not. What could be wrong? This is a classic sign of PCR inhibition. Many biological samples contain contaminants that co-purify with DNA and can inhibit the polymerase. To troubleshoot:

- Check DNA Quality: Ensure the A260/A280 ratio is ~1.8.

- Dilute the Template: Diluting the sample may reduce the concentration of inhibitors.

- Add More Enzyme: Increasing the amount of DNA polymerase by 10–20% can sometimes overcome mild inhibition [2].

- Use a Robust Master Mix: Some master mixes, like certain PACE variants, are specifically formulated for better performance with crude DNA samples [1].

Q3: I switched to a new batch of master mix, and my established assay failed. What should I do? This unexpected issue, while frustrating, does occur. Different PCR assays can show individual sensitivity to minute changes in reaction mixture components, even between batches of the same product [5]. The solution is to:

- Validate New Batches: Always test a new batch of any reagent alongside the old one using a core set of your established assays before putting it into widespread use [6] [5].

- Maintain a Backup: For critical diagnostic assays, it is prudent to have protocols validated for master mixes from more than one manufacturer to ensure continuity [5].

Troubleshooting Common PCR Problems

Table 3: Troubleshooting Guide for Common Master Mix-Related Issues

| Problem | Potential Causes | Solutions |

|---|---|---|

| No or Low Amplification | - Insufficient free Mg²⁺ [4]- Low dNTP concentration [2]- Inactive enzyme or incorrect buffer | - Optimize MgCl₂ concentration.- Verify dNTP concentration and quality.- Test enzyme activity with a control template. |

| Nonspecific Bands / Primer-Dimers | - Excessive Mg²⁺ concentration [3] [4]- Primer concentration too high [2]- Low annealing temperature | - Titrate Mg²⁺ to the lowest effective concentration.- Lower primer concentration (e.g., to 0.1–0.3 µM).- Increase annealing temperature incrementally. |

| Poor Reproducibility | - Inconsistent reagent mixing/thawing [6]- Master mix not adequately mixed before aliquoting | - Ensure all components are thoroughly mixed after thawing.- Vortex and centrifuge the master mix before use. |

Experimental Protocol: Optimizing Mg²⁺ Concentration for a Novel Assay

This protocol provides a detailed methodology for determining the optimal MgCl₂ concentration for a new PCR assay, a critical step in assay validation.

Objective: To identify the MgCl₂ concentration that yields the highest specific amplification yield with minimal background for a given primer-template system.

Materials:

- DNA polymerase with supplied magnesium-free reaction buffer [3]

- Separate 25 mM MgCl₂ stock solution

- dNTP mix (10 mM each)

- Forward and reverse primers (10 µM each)

- Template DNA (e.g., 20 ng/µL genomic DNA)

- Nuclease-free water

- PCR tubes and thermal cycler

Method:

- Prepare the Master Mix Base: Create a master mix containing all components except the template DNA and MgCl₂. Calculate for one extra reaction to account for pipetting error.

- 5.0 µL of 10x Magnesium-Free Buffer

- 1.0 µL of dNTP Mix (10 mM each)

- 1.0 µL of Forward Primer (10 µM)

- 1.0 µL of Reverse Primer (10 µM)

- 0.5 µL of DNA Polymerase (e.g., 1.25 U/µL)

- 35.5 µL of Nuclease-free Water Total Volume (without Mg²⁺ and template): 44 µL per reaction

Aliquot and Add MgCl₂: Aliquot 44 µL of the master mix base into each of six PCR tubes. Add MgCl₂ from the 25 mM stock to achieve the desired final concentrations in the 50 µL reaction, as shown below.

Add Template and Run PCR: Add 5 µL of template DNA to each tube, mix gently, and centrifuge. Run the PCR using the predetermined thermal cycling conditions.

Analyze Results: Analyze the PCR products using agarose gel electrophoresis. The lane with the brightest specific band and the least nonspecific product or primer-dimer indicates the optimal Mg²⁺ concentration.

Table 4: Sample Setup for Mg²⁺ Titration Experiment

| Tube | Master Mix Base (µL) | 25 mM MgCl₂ (µL) | Template DNA (µL) | Final [MgCl₂] in 50 µL |

|---|---|---|---|---|

| 1 | 44 | 0.0 | 5 | 0.0 mM (Negative Control) |

| 2 | 44 | 1.0 | 5 | 1.0 mM |

| 3 | 44 | 1.5 | 5 | 1.5 mM |

| 4 | 44 | 2.0 | 5 | 2.0 mM |

| 5 | 44 | 2.5 | 5 | 2.5 mM |

| 6 | 44 | 3.0 | 5 | 3.0 mM |

Schematic: Role of Mg²⁺ in the Polymerase Reaction Mechanism

The following diagram illustrates the molecular mechanism of how magnesium ions facilitate the catalytic function of DNA polymerase at the active site, based on structural studies [7].

In the realm of biomedical PCR assay development, master mix optimization is foundational to success. The choice of DNA polymerase is arguably the most critical variable in this optimization, directly impacting the specificity, yield, and accuracy of amplification. This guide provides a detailed comparative analysis of three primary polymerase categories—Taq, High-Fidelity, and Hot-Start—framed within the context of troubleshooting common experimental challenges. Designed for researchers and drug development professionals, this resource offers structured data, protocols, and decision frameworks to streamline your enzyme selection process and enhance assay reproducibility.

Taq DNA Polymerase

Taq DNA polymerase, derived from Thermus aquaticus, is the workhorse enzyme for routine PCR but has defined limitations.

- Key Characteristics: Lacks 3'→5' proofreading exonuclease activity, resulting in lower replication fidelity [8]. It catalyzes non-template-dependent addition of a single nucleotide (typically an adenosine) to the 3' end of PCR products, generating "A-overhangs" suitable for TA cloning [9].

- Primary Limitations: Its key constraints are low specificity (prone to nonspecific amplification and primer-dimer formation) and low fidelity (error rates typically around 1-20 x 10⁻⁵, or 1 error per 200-500 bases in a 3-kb amplicon) [8] [10] [11].

High-Fidelity DNA Polymerase

High-fidelity polymerases are engineered for applications requiring precise DNA sequence replication, such as cloning, sequencing, and site-directed mutagenesis [12] [13].

- Mechanism of Accuracy: These enzymes achieve high accuracy through two mechanisms: (1) an optimized polymerase active site with superior discrimination against incorrect nucleotides, and (2) a 3'→5' proofreading exonuclease activity that excises misincorporated nucleotides [13] [11].

- Examples and Performance: Enzymes like Pfu (from Pyrococcus furiosus) and engineered blends like Q5 High-Fidelity DNA Polymerase offer error rates up to 50-300 times lower than Taq [12] [9]. Q5 polymerase, for instance, is fused to the Sso7d DNA-binding domain, enhancing its processivity and ability to amplify long and difficult templates [13].

Hot-Start DNA Polymerase

Hot-Start polymerases are engineered to remain inactive at room temperature, preventing enzymatic activity during PCR reaction setup [12].

- Mechanism: This is typically achieved by binding the enzyme with inhibitory antibodies, using heat-labile chemical modifications, or aptamers that block the active site. The inhibitor is denatured during the initial PCR denaturation step (e.g., >90°C), activating the enzyme [12] [14].

- Key Advantage: This technology drastically reduces nonspecific amplification and primer-dimer formation, improving assay sensitivity, specificity, and yield. It also enables convenient room-temperature setup for high-throughput applications [12].

Table 1: Quantitative Comparison of Common DNA Polymerases

| Polymerase Type | Example Enzymes | Proofreading (3'→5' Exo) | Fidelity (Relative to Taq) | Error Rate | Resulting Ends | Key Applications |

|---|---|---|---|---|---|---|

| Standard Taq | Taq DNA Polymerase | No | 1x | ~1.3-1.8 x 10⁻⁴ [9] | 3'A Overhang | Routine PCR, genotyping |

| Hot-Start Taq | Hot Start Taq DNA Polymerase | No | ~1x | Similar to Standard Taq | 3'A Overhang | Routine PCR with improved specificity |

| High-Fidelity | Q5 High-Fidelity, Phusion Hot Start | Yes (++++ ) | 50x - 280x [9] | <1 x 10⁻⁶ [13] | Blunt | Cloning, sequencing, NGS |

| High-Fidelity Hot-Start | Q5 Hot Start, Hot-Start Hifi Polymerase [14] | Yes (++++ ) | >50x | ~1 x 10⁻⁶ | Blunt | Sensitive cloning, NGS library prep |

| Long-Range | LongAmp Taq | Yes (++ ) | ~2x [9] | N/A | 3'A/Blunt | Long-range PCR (>5 kb) |

Troubleshooting Guides & FAQs

Frequently Asked Questions (FAQs)

Q1: My PCR yields multiple nonspecific bands or a high background smear. How can I improve specificity?

- Problem: Nonspecific amplification due to polymerase activity during reaction setup at room temperature.

- Solution: Use a Hot-Start DNA Polymerase. The antibody-mediated or chemically modified inhibition prevents activity until the first high-temperature denaturation step, dramatically reducing primer-dimer and misprimed amplification [12].

- Protocol: When setting up your master mix, use a validated hot-start enzyme. Ensure the initial denaturation step is sufficient (typically 30 seconds to 2 minutes at 98°C) to fully activate the enzyme. Setting up reactions on ice can provide an additional layer of precaution.

Q2: I am cloning a PCR product, but a high percentage of my clones have mutations in the inserted sequence. What is the cause and solution?

- Problem: The error rate of standard Taq polymerase is too high for cloning applications.

- Solution: Switch to a High-Fidelity DNA Polymerase with proofreading activity. Enzymes like Q5 or Pfu offer error rates that are orders of magnitude lower [13] [10].

- Protocol:

- Use a high-fidelity polymerase and its recommended buffer.

- Minimize PCR cycle numbers to reduce the accumulation of stochastic errors.

- For blunt-ended cloning strategies, ensure the polymerase generates blunt ends (e.g., Q5, Pfu). If using a TA-cloning strategy, a dedicated A-tailing step may be required post-amplification.

Q3: How do I decide between a high-fidelity polymerase and Taq for my diagnostic assay, where the readout is just presence/absence of a product?

- Problem: Uncertainty about fidelity requirements for non-sequencing applications.

- Solution: For qualitative yes/no detection, Taq or Hot-Start Taq is often sufficient and more cost-effective [11]. High fidelity is less critical when the sequence itself is not analyzed, such as in genotyping or pathogen detection. The priority should be on specificity and yield, making a robust hot-start enzyme an excellent choice [12] [11].

Q4: My target is GC-rich or has complex secondary structure. Which polymerase should I use?

- Problem: Polymerases with low processivity struggle with difficult templates.

- Solution: Use a highly processive polymerase, often an engineered high-fidelity enzyme. Look for polymerases fused to processivity-enhancing domains like Sso7d, which improve the enzyme's ability to remain bound to the template and unwind secondary structures [12] [13].

- Protocol: Combine a high-processivity enzyme (e.g., Q5, Platinum II Taq) with specialized buffers or additives like DMSO, betaine, or GC enhancers. A thermal cycling protocol with a higher denaturation temperature may also be beneficial.

Decision Workflow for Polymerase Selection

The following diagram illustrates the logical decision-making process for selecting the most appropriate DNA polymerase based on your experimental goals and template characteristics.

Experimental Protocols & Methodologies

Protocol 1: Assessing Fidelity via Cloning and Sequencing

This method directly sequences cloned PCR products to determine polymerase error rates across a large DNA sequence space [10].

- Materials: High-fidelity and Taq polymerases, target plasmid DNA, primers, cloning kit, sequencing reagents.

- Procedure:

- Amplification: Amplify your target gene from a plasmid template (e.g., 25 pg/reaction) using the polymerases you are comparing. Use a sufficient number of cycles (e.g., 30) to maximize observable errors.

- Cloning: Purify the PCR products and clone them into a suitable vector using a system like Gateway or traditional restriction/ligation.

- Sequencing: Pick multiple individual colonies (e.g., 50-100 per polymerase) and prepare plasmid DNA for Sanger sequencing of the entire insert.

- Analysis: Align sequences to the known original template. Count all mutations (substitutions, insertions, deletions). Calculate the error rate using the formula: Error Rate = (Total Mutations Observed) / (Total Base Pairs Sequenced). The number of template doublings during PCR can also be factored in for a more precise measurement [10].

Protocol 2: Evaluating Specificity with Hot-Start Activation

This protocol visually demonstrates the effectiveness of hot-start technology in reducing nonspecific amplification [12].

- Materials: Hot-Start DNA Polymerase, non-hot-start version of the same enzyme, template DNA (e.g., human genomic DNA), primers, agarose gel electrophoresis system.

- Procedure:

- Reaction Setup: Prepare two identical PCR master mixes targeting a specific gene. To one tube, add the standard polymerase; to the other, add the hot-start version.

- Incubation (Optional): To rigorously test the hot-start mechanism, incubate the assembled reactions at room temperature for 30-60 minutes before placing them in the thermal cycler.

- Amplification: Run the PCR using the manufacturer's recommended cycling conditions.

- Analysis: Analyze the PCR products on an agarose gel. The reaction with the hot-start polymerase should show a single, clean band of the expected size, while the standard polymerase may show multiple nonspecific bands and primer-dimer [12].

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Reagents for PCR Master Mix Optimization

| Reagent / Material | Function / Description | Key Considerations |

|---|---|---|

| DNA Polymerase | Enzyme that synthesizes new DNA strands. The core component of any PCR. | Choice depends on balance of fidelity, speed, and specificity (see Table 1). |

| 5'→3' Exonuclease | Activity present in some polymerases (e.g., Taq) that degrades DNA ahead of the polymerase. | Required for probe-based qPCR assays (e.g., TaqMan). |

| Proofreading Activity (3'→5' Exo) | Corrects misincorporated nucleotides, drastically improving fidelity. | Essential for cloning and sequencing; often produces blunt-ended products [12] [13]. |

| dNTP Mix | The building blocks (dATP, dCTP, dGTP, dTTP) for DNA synthesis. | Quality and concentration are critical for high yield and fidelity. Imbalances can increase error rates. |

| PCR Buffer with MgCl₂ | Provides optimal ionic strength and pH. Mg²⁺ is a essential cofactor for polymerase activity. | Mg²⁺ concentration often requires optimization; it affects primer annealing, enzyme activity, and fidelity [15]. |

| Hot-Start Modifier | Antibody or chemical inhibitor that blocks polymerase activity until initial denaturation. | Crucial for improving specificity and enabling room-temperature setup [12] [14]. |

| PCR Enhancers | Additives like betaine, DMSO, or proprietary commercial blends. | Help amplify difficult templates (GC-rich, high secondary structure) by lowering melting temperature or disrupting structures [15]. |

Frequently Asked Questions (FAQs)

FAQ 1: What are the primary advantages of using a ready-to-use master mix compared to preparing individual components? Ready-to-use master mixes significantly enhance convenience and standardization. They contain all essential PCR components except for the primers and template DNA, which speeds up hands-on time and reduces the risk of pipetting errors or contamination during reaction setup [5]. This contributes to better inter-laboratory reproducibility by ensuring a consistent baseline reaction environment [16].

FAQ 2: Can I expect perfect reproducibility when switching to a new batch of the same master mix brand? While manufacturers strive for consistency, batch-to-batch variability can occur and may unexpectedly impact specific, validated PCR assays. One case study reported a new batch from a reputable manufacturer failing to amplify a specific Lassa virus target, despite functioning correctly for other assays like Yellow Fever virus. This highlights that different assays can show individual sensitivity to minute changes in the reaction mixture, even when the product specification is unchanged [5]. It is recommended to quality-control new batches with a full panel of in-house assays before implementing them in critical diagnostics [5].

FAQ 3: My master mix-based PCR failed. What are the first steps in troubleshooting? Start by verifying the components you added: template quality and concentration, and primer integrity and specificity [17] [16]. If these are confirmed, test the master mix itself by using a previously validated control assay with known performance. If the control works, the issue is likely with your assay-specific components or design. If the control fails, consider trying a new aliquot of master mix or a different manufacturer's product [5].

FAQ 4: How do I choose the right master mix for a specific application, such as amplifying GC-rich templates? Select a master mix specifically formulated for challenging templates. For GC-rich regions, high-performance mixes often include specialized additives or co-solvents that help denature secondary structures [17] [18]. Always review the manufacturer's instructions and application notes, as they provide recommended conditions optimized for their specific enzyme and buffer system [16].

Troubleshooting Guides

Guide: "No Amplification" or "Weak Amplification"

This guide addresses the issue of absent or faint PCR products when using a ready-to-use master mix.

Table 1: Troubleshooting "No Amplification" or "Weak Amplification"

| Observation | Possible Cause | Recommended Solution |

|---|---|---|

| No amplification in test and positive control | Master mix failure or incompatibility | Use a new aliquot of master mix. Verify functionality with a control assay. If problem persists, switch to a different manufacturer's master mix [5]. |

| Weak or no amplification in test samples only | Poor template quality or quantity; PCR inhibitors | Re-quantify template DNA. Re-purify template to remove inhibitors like salts, EDTA, or phenol [17] [19]. Analyze DNA integrity by gel electrophoresis [20]. |

| Suboptimal cycling conditions | Increase the number of PCR cycles (e.g., to 35-40) for low-copy templates [17] [18]. Optimize denaturation and annealing temperatures [19]. | |

| Incorrect primer design or degradation | Verify primer sequence and specificity. Use fresh primer aliquots to avoid freeze-thaw degradation [17] [16]. |

Guide: "Non-Specific Amplification" or "Multiple Bands"

This guide helps resolve issues where the PCR produces unwanted, non-target products.

Table 2: Troubleshooting "Non-Specific Amplification"

| Observation | Possible Cause | Recommended Solution |

|---|---|---|

| Multiple bands on a gel | Annealing temperature too low | Increase the annealing temperature stepwise in 1-2°C increments. Use a gradient cycler to determine the optimal temperature [17] [19]. |

| Primer concentration too high | Optimize primer concentration, typically between 0.1–1 µM. High concentrations promote mispriming and primer-dimer formation [17] [18]. | |

| Enzyme activity at low temperatures | Use a hot-start DNA polymerase, which is inactive until the initial denaturation step, to prevent non-specific amplification during reaction setup [17] [19]. | |

| Excessive cycle number | Reduce the number of PCR cycles to prevent accumulation of non-specific amplicons in later cycles [17]. |

Experimental Protocols for Validation and Optimization

Protocol: Quality Control of a New Master Mix Batch

Purpose: To ensure a new batch of ready-to-use master mix performs equivalently to the current batch for all critical in-house assays.

Background: Batch-to-batch variability, though rare, can cause complete assay failure. Relying on a single assay for quality control is insufficient, as different assays can be sensitive to subtle changes in buffer composition [5].

Materials:

- Old and new batches of ready-to-use master mix.

- Nuclease-free water.

- Validated primer sets for a panel of in-house assays (including the most sensitive and critical ones).

- Positive control templates (e.g., plasmid DNA, in vitro transcribed RNA for RT-PCR) for each assay.

- Real-time PCR instrument or thermal cycler.

Methodology:

- Reaction Setup: For each assay in the panel, prepare two parallel reactions.

- Reaction A: Use the old, validated batch of master mix.

- Reaction B: Use the new batch of master mix.

- Keep all other components (primers, template, water) identical and from the same source.

- Amplification: Run the PCR or RT-PCR under standard cycling conditions for each assay.

- Analysis:

- For qPCR: Compare the quantification cycle (Cq) values and amplification curve shapes between Reaction A and B. A significant shift in Cq (> 1 cycle) or poor curve kinetics in Reaction B indicates a problem with the new batch for that specific assay.

- For conventional PCR: Compare amplicon yield and specificity via gel electrophoresis.

Troubleshooting Note: If an assay fails only with the new batch, contact the manufacturer. It is prudent to maintain validated protocols for a master mix from a secondary manufacturer for critical diagnostic applications [5].

Protocol: Optimizing a Master Mix for a Novel Assay

Purpose: To establish robust cycling conditions and component ratios when developing a new PCR assay with a ready-to-use master mix.

Materials:

- Ready-to-use master mix.

- Forward and reverse primers (10 µM stock).

- Template DNA.

- Nuclease-free water.

- Thermal cycler with gradient functionality.

Methodology:

- Annealing Temperature Optimization:

- Prepare a master mix containing all components (master mix, primers, template, water).

- Aliquot the mix into a PCR tube strip.

- Use the thermal cycler's gradient function to run a PCR with an annealing temperature range (e.g., 50°C to 65°C).

- Analyze results by gel electrophoresis or qPCR melt curve analysis to identify the temperature that yields the strongest specific product with minimal background [19].

- Primer Concentration Titration:

- Prepare a series of reactions where the final primer concentration is varied (e.g., 0.1 µM, 0.25 µM, 0.5 µM, 1.0 µM).

- Run the PCR at the optimal annealing temperature determined in step 1.

- Analyze the results to find the concentration that provides maximum yield without increasing non-specific products or primer-dimers [18].

The workflow for this optimization process is outlined in the diagram below.

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Reagents for PCR Assay Development and Troubleshooting

| Item | Function | Key Considerations |

|---|---|---|

| High-Fidelity Master Mix | Amplification with very low error rates, essential for cloning and sequencing. | Contains DNA polymerases with proofreading (3'→5' exonuclease) activity. Use for downstream applications requiring high sequence accuracy [19]. |

| Hot-Start Master Mix | Prevents non-specific amplification and primer-dimer formation during reaction setup. | The polymerase is inactive until a high-temperature activation step. Greatly improves specificity and yield, especially for complex targets [17] [18]. |

| GC Enhancer / Additives | Aids in denaturing DNA secondary structures and high GC-rich regions. | A specialized additive included in some master mixes or available separately. Critical for amplifying difficult templates [17] [19]. |

| dNTP Mix | Provides the nucleotide building blocks (dATP, dCTP, dGTP, dTTP) for DNA synthesis. | Must be fresh and at equimolar concentrations to prevent misincorporation and reduced fidelity [17] [19]. |

| MgCl₂ Solution | Essential co-factor for DNA polymerase activity. | Concentration is often pre-optimized in master mixes. If adjusting separately, optimize in 0.2-1 mM increments, as excess Mg²⁺ can cause non-specific binding [17] [20]. |

The PCR Master Mix market is poised for significant expansion, driven by its critical role in molecular diagnostics and life sciences research. The market's growth is characterized by several key quantitative metrics and regional dynamics.

Global Market Size and Growth Projections

The following table summarizes the core market data and projected growth:

| Market Metric | Value / Projection | Time Period / CAGR |

|---|---|---|

| Global PCR Master Mix Market Size | ~USD 1.5 Billion [21] | Base Year 2025 (est.) |

| Global PCR Master Mix Market Size | ~USD 2.8 Billion [21] | Projected 2033 |

| Compound Annual Growth Rate (CAGR) | ~8% [21] | Forecast Period 2025-2033 |

| Hot-Start PCR Master Mix Segment Value | ~USD 476 Million [22] | Base Year 2025 (est.) |

| Hot-Start PCR Master Mix Segment CAGR | 7.3% [22] | Forecast Period 2025-2033 |

| High-Fidelity PCR Master Mix Segment Value | >USD 1.2 Billion [21] | Projected 2028 |

Market Drivers and Segment Dynamics

Market growth is fueled by several interconnected drivers. The rising prevalence of infectious diseases and the expansion of personalized medicine create sustained demand for reliable molecular diagnostics [21]. Technologically, the industry is shifting towards multiplexing capabilities and automation-compatible formulations to increase laboratory throughput and efficiency [21]. A key trend is the move towards specialized formulations like hot-start and high-fidelity mixes that enhance specificity, sensitivity, and ease-of-use [23] [22] [21].

Geographically, North America, particularly the United States, currently dominates the market due to its robust research infrastructure, high healthcare expenditure, and presence of key market players [22] [21]. However, the Asia-Pacific region is expected to witness the most rapid growth, fueled by increasing healthcare investments and a growing biotechnology research landscape [22] [21].

Technical Support Center: Troubleshooting and FAQs

This section provides practical guidance for researchers encountering issues with PCR master mixes, framed within the context of optimizing biomedical PCR assays.

Frequently Asked Questions (FAQs)

What is a PCR Master Mix? A PCR Master Mix is a pre-made, ready-to-use solution containing all the core components necessary for a polymerase chain reaction, except for the template DNA and gene-specific primers. Typical components include a thermostable DNA polymerase (e.g., Taq), dNTPs, MgCl₂, and optimized reaction buffers [24] [25].

What are the main advantages of using a Master Mix? Using a master mix significantly reduces pipetting steps, minimizing the risk of pipetting errors and cross-contamination. It enhances reproducibility across experiments, saves preparation time, and ensures reactions are set up with optimized concentrations of key components [24] [25].

How should I store the PCR Master Mix, and what is its shelf life? Master mixes should be stored at -20°C to -80°C to maintain enzyme activity and reagent stability. You should avoid repeated freeze-thaw cycles, which can degrade performance. Shelf life is typically 6 to 12 months when stored properly at -20°C, but always consult the manufacturer's datasheet for specific recommendations [25].

My assay failed after switching to a new batch of master mix. What could be wrong? While manufacturers perform quality control, some PCR assays can be uniquely sensitive to minute, uncharacterized changes in buffer composition between batches [5]. This can result in a complete failure for one assay while others perform normally. It is critical to validate new reagent batches with a key assay before full implementation and, for essential diagnostics, to have a validated protocol using a master mix from an alternative manufacturer [5].

What is the purpose of a Hot-Start Master Mix? Hot-Start polymerases are engineered to be inactive at room temperature. This mechanism prevents non-specific amplification and primer-dimer formation that can occur during reaction setup before the PCR cycle begins, thereby significantly improving the specificity and yield of the desired product [22] [17].

Advanced Troubleshooting Guide

This guide addresses common experimental problems and their solutions.

Problem: No Amplification or Low Yield

| Possible Cause | Solution / Experimental Protocol |

|---|---|

| Incorrect Annealing Temperature | Recalculate primer Tm values and test an annealing temperature gradient, starting at 5°C below the lower Tm of the primer pair [26]. |

| Poor Template Quality or Quantity | Protocol: Analyze template DNA integrity via gel electrophoresis (for degradation) and check purity using A260/A280 ratio. Re-purify template if contaminated with inhibitors like phenol or salts. Adjust input amount (e.g., 1 pg–10 ng for plasmid, 1 ng–1 µg for genomic DNA) [17] [26]. |

| Inactive or Missing Reagent | Include positive control primers. Test a new aliquot of master mix. Ensure all reaction components were added [5] [26]. |

| PCR Inhibitors in Sample | Protocol: Further purify the DNA template by alcohol precipitation or using a commercial PCR cleanup kit (e.g., Monarch Spin Columns). Alternatively, dilute the template sample to reduce inhibitor concentration [17] [26]. |

Problem: Multiple Bands or Non-Specific Products

| Possible Cause | Solution / Experimental Protocol |

|---|---|

| Primer Annealing Temperature Too Low | Increase the annealing temperature stepwise in 1–2°C increments. Use a gradient thermal cycler for optimization [17] [26]. |

| Non-Hot-Start Polymerase Activity | Switch to a hot-start DNA polymerase. Set up reactions on ice and use a thermal cycler with a heated lid, pre-heated to the denaturation temperature [17] [26]. |

| Excess Mg²⁺ Concentration | Protocol: Optimize Mg²⁺ concentration by testing increments of 0.2–1.0 mM. Thoroughly mix the Mg²⁺ solution and buffer before use [26]. |

| Poor Primer Design/Specificity | Verify primer sequences for specificity and lack of self-complementarity (which causes primer-dimers). Use primer design software and consider increasing primer length [17] [26]. |

Problem: Contamination (False Positives)

Contamination is a critical issue, particularly in diagnostic settings. The workflow below outlines a systematic approach to prevention and identification.

Systematic Isolation Protocol: If your No-Template Control (NTC) is positive, set up a series of reactions where you replace one component at a time with a new, trusted aliquot.

- Start by replacing the PCR-grade water [27].

- If contamination persists, test a new aliquot of the master mix [27] [5].

- Continue by testing new aliquots of primers and probes [27].

- If the source remains elusive, discard all open reagents and perform a full decontamination of workspaces and equipment with a 10% bleach solution, followed by DNA-free water [27].

The Scientist's Toolkit: Essential Research Reagent Solutions

The table below details key materials and reagents crucial for successful and reliable PCR experimentation.

| Item | Function / Explanation |

|---|---|

| Hot-Start Master Mix | The cornerstone reagent for most modern PCR assays. Its engineered polymerase reduces pre-amplification mishaps, providing greater specificity, sensitivity, and yield [22] [17]. |

| High-Fidelity Master Mix | Essential for cloning, sequencing, and mutagenesis. These mixes contain polymerases with proofreading (3'→5' exonuclease) activity, resulting in significantly lower error rates during amplification [21] [26]. |

| PCR-Grade Water | A critical, often overlooked reagent. It is nuclease-free and certified to contain no contaminating DNA or PCR inhibitors, preventing false positives and reaction failure [27] [17]. |

| Aerosol-Resistant Filter Tips | Used in all pre-PCR setup areas to prevent aerosol-borne contamination of samples and reagents, a primary source of DNA carryover and false positives [27]. |

| dNTP Mix | Deoxynucleotide triphosphates (dATP, dCTP, dGTP, dTTP) are the building blocks for new DNA strands. Provided in master mixes at optimized, balanced concentrations to prevent misincorporation errors [24] [26]. |

| MgCl₂ / MgSO₄ Solution | Magnesium ions are a essential cofactor for DNA polymerase activity. Its concentration is often optimized and is included in the master mix buffer [17] [26]. |

| PCR Additives (e.g., GC Enhancer) | Reagents like DMSO, betaine, or proprietary GC enhancers help denature complex templates with high GC-content or secondary structures, facilitating polymerase progression [17] [26]. |

| Uracil-DNA Glycosylase (UNG) | An enzymatic system to prevent PCR product carryover contamination. Using dUTP in the PCR creates uracil-containing amplicons. UNG treatment in a subsequent pre-PCR step degrades these contaminants while leaving native DNA templates intact [27]. |

Advanced Formulations and Protocols for Complex Biomedical Applications

In biomedical PCR assays, the quality of your results is fundamentally dependent on the compatibility between your master mix and the DNA template you are amplifying. Challenging templates, such as those with high GC-content, high AT-content, or those requiring long amplicons, present unique obstacles that standard PCR protocols often fail to overcome. These challenges include secondary structure formation, premature enzyme activity, and polymerase stalling, which can lead to PCR failure, non-specific amplification, or the introduction of mutations [28] [17] [29]. Master mix optimization is therefore not a luxury but a necessity for obtaining reliable, reproducible data in critical applications like drug target validation and diagnostic assay development.

This guide provides targeted troubleshooting strategies and FAQs to help you select and tailor the right master mix for your most demanding templates, ensuring amplification success and data integrity in your research.

FAQ: Addressing Common PCR Challenges

Q1: What makes GC-rich templates so difficult to amplify, and what are the key strategies for success?

GC-rich templates (typically defined as sequences with over 60% GC content) are challenging primarily due to their thermal stability and tendency to form secondary structures [28] [29]. The strong triple hydrogen bonds of G-C base pairs require more energy to break than A-T pairs, leading to higher melting temperatures. This stability promotes the formation of rigid secondary structures like hairpin loops, which can block polymerase progression and result in incomplete or failed amplification [29].

Key strategies for amplifying GC-rich regions include:

- Polymerase Choice: Use polymerases specifically engineered for GC-rich templates. These often come with specialized buffers or compatible GC Enhancers that contain additives to help destabilize secondary structures. Examples include OneTaq Hot Start DNA Polymerase with GC Buffer and Q5 High-Fidelity DNA Polymerase with its GC Enhancer [28] [30].

- Additives: Incorporate co-solvents like DMSO, glycerol, or betaine. These additives work by reducing the formation of secondary structures that inhibit the polymerase, thereby improving the yield of your target amplicon [17] [29].

- Thermal Cycling Adjustments: Increase the denaturation temperature (e.g., to 95-98°C) for the first few cycles to help melt stubborn secondary structures. Be cautious, as prolonged high temperatures can reduce polymerase activity over many cycles [29].

- Mg²⁺ Concentration Optimization: Fine-tune the MgCl₂ concentration, as GC-rich templates may require altered magnesium levels for optimal polymerase activity and primer binding. A gradient PCR in 0.5 mM increments between 1.0 and 4.0 mM can help find the ideal concentration [28] [17].

Q2: Are AT-rich templates problematic, and how can their amplification be improved?

While less frequently discussed than GC-rich templates, AT-rich sequences present their own set of challenges. The primary issue is low thermal stability due to the weaker two-hydrogen bonds of A-T base pairs. This can lead to low melting temperatures, making it difficult to find an annealing temperature that is both specific and efficient. Furthermore, AT-rich regions can form unusual secondary structures and are more prone to spurious primer binding and mis-priming [17].

Optimization approaches for AT-rich templates include:

- Lower Annealing Temperatures: Use an annealing temperature closer to the primer Tm, or employ a temperature gradient to find the optimal balance between specificity and yield [17] [30].

- Reduced Denaturation Temperature: Lower the denaturation temperature slightly (e.g., to 90-92°C) to prevent excessive strand separation and potential template damage.

- Enzyme Selection: A hot-start polymerase is highly recommended to prevent non-specific amplification and primer-dimer formation that can occur at lower temperatures during reaction setup [17] [22].

Q3: What are the critical factors when attempting to amplify long amplicons?

Amplifying long targets (generally >5 kb) pushes the limits of standard PCR. The main challenges include polymerase processivity, enzyme fidelity, and the accumulation of truncated products due to incomplete extension or template damage [17].

To successfully generate long amplicons, consider the following:

- High-Processivity Polymerases: Choose enzymes specifically designed for long-range PCR. These polymerases often combine a high-fidelity, proofreading main enzyme with a processive companion enzyme to ensure efficient and accurate amplification over long distances [17].

- Extended Extension Times: Calculate extension times based on the polymerase's speed (e.g., 1-2 minutes per kb for most enzymes) and be prepared to extend the time in later cycles [17] [31].

- Template Quality and Integrity: The DNA template must be of high molecular weight and integrity. Sheared or nicked DNA will prevent the amplification of full-length products. Always verify template quality by gel electrophoresis before attempting long-range PCR [17].

- Buffer Optimization: Ensure the reaction buffer provides adequate pH buffering and salt concentrations to support prolonged incubation times and stable enzyme activity [31].

Q4: What is a "Hot-Start" master mix, and when should I use it?

A Hot-Start PCR Master Mix contains a DNA polymerase that is intentionally rendered inactive until a high-temperature activation step (usually the initial denaturation) is applied [32] [22]. This technology is crucial for improving amplification specificity.

You should use a hot-start master mix in the following scenarios:

- To minimize non-specific amplification and primer-dimer formation [32] [22].

- When amplifying low-copy-number targets.

- When using complex templates like genomic DNA.

- In multiplex PCR assays, where multiple primer sets are used simultaneously.

- For any highly sensitive diagnostic or research assay where specificity and reproducibility are paramount [21] [32].

Q5: How does polymerase fidelity impact my downstream applications, and how do I choose?

Polymerase fidelity refers to the accuracy with which an enzyme copies the DNA template, measured as its error rate. Low-fidelity polymerases (e.g., standard Taq) can introduce mutations during amplification. For downstream applications like cloning, sequencing, and functional analysis, these mutations can lead to erroneous results [32] [30].

Select your polymerase based on your application:

- Routine PCR and genotyping: Standard Taq polymerase may be sufficient.

- Cloning, sequencing, and mutant analysis: Use a high-fidelity polymerase (e.g., Q5 High-Fidelity DNA Polymerase, which has an error rate ~280 times lower than Taq) [28] [30]. High-fidelity polymerases often possess 3'→5' exonuclease (proofreading) activity that corrects misincorporated nucleotides.

Troubleshooting Guide: Master Mixes for Challenging Templates

Table 1: Troubleshooting Common PCR Amplification Issues

| Observed Problem | Potential Causes | Recommended Solutions |

|---|---|---|

| No Product | • Excessively high annealing temperature• Poor primer design• Complex GC-rich template• Insufficient Mg²⁺ | • Perform gradient PCR to optimize annealing temperature [17] [30]• Verify primer specificity and design [31]• Switch to a polymerase/GC enhancer system [28] [29]• Titrate Mg²⁺ concentration [28] [17] |

| Smearing or Multiple Bands | • Low annealing temperature• Excess Mg²⁺• Non-hot-start polymerase activity | • Increase annealing temperature stepwise [17] [30]• Reduce Mg²⁺ concentration in 0.2-1 mM increments [30]• Use a hot-start master mix [32] [22] |

| Unexpected Product Size | • Mispriming due to poor primer specificity• Secondary structures in template | • Blast check primer specificity [31]• Use a touchdown PCR protocol• Add DMSO or other additives to disrupt structures [17] [29] |

| Poor Yield with Long Amplicons | • Insufficient extension time• Polymerase lacking processivity• Degraded template | • Increase extension time according to polymerase speed and amplicon length [17]• Switch to a specialized long-range PCR polymerase [17]• Check template integrity on a gel [17] |

| Sequence Errors in Clones | • Low-fidelity polymerase• Too many PCR cycles• Unbalanced dNTPs | • Use a high-fidelity, proofreading polymerase [32] [30]• Reduce the number of amplification cycles [30]• Use fresh, equimolar dNTP mixtures [30] |

Experimental Protocol: Optimizing a PCR Assay for a GC-Rich Target

This protocol provides a step-by-step methodology for developing a robust PCR assay for a challenging GC-rich target, incorporating key optimization strategies.

Materials and Reagents

Table 2: Research Reagent Solutions for GC-Rich PCR Optimization

| Reagent | Function/Description |

|---|---|

| High-Quality Template DNA | Intact, purified DNA from your source (e.g., cell line, tissue). Store in TE buffer or nuclease-free water [17]. |

| Specialized DNA Polymerase | A polymerase known for amplifying difficult templates (e.g., OneTaq or Q5 from NEB; AccuPrime from ThermoFisher) [28] [29]. |

| GC Enhancer / Additives | Proprietary buffer (e.g., OneTaq GC Buffer) or additives like DMSO, betaine, or glycerol to disrupt secondary structures [28] [29]. |

| MgCl₂ or MgSO₄ Solution | Magnesium salt solution for separate titration, if not included in the buffer at a fixed concentration [28] [17]. |

| Optimized Primer Pair | Primers designed according to best practices (length 15-30 bp, GC content 40-60%, Tm within 5°C of each other) [31]. |

| dNTP Mix | Balanced mixture of all four deoxynucleotides to prevent misincorporation [30]. |

Step-by-Step Procedure

Initial Setup with GC-Enhanced Master Mix:

- Prepare a 50 µL reaction on ice using the specialized polymerase and its accompanying GC buffer or enhancer according to the manufacturer's instructions [28].

- Example Reaction Setup:

- 10 µL: 5X GC Reaction Buffer

- 1 µL: 10 mM dNTP Mix

- 2.5 µL: Forward Primer (10 µM)

- 2.5 µL: Reverse Primer (10 µM)

- X µL: Template DNA (10-100 ng)

- 0.5 µL: Specialized DNA Polymerase

- Y µL: GC Enhancer (if required separately)

- Z µL: Nuclease-Free Water to 50 µL final volume

Thermal Cycling with a Stepped Protocol:

- Initial Denaturation: 98°C for 2 minutes (activates hot-start polymerase).

- Cycling (30-35 cycles):

- Denaturation: 98°C for 20 seconds. Use a higher temperature for the first 5 cycles (e.g., 98°C) to help melt stubborn structures [29].

- Annealing: Use a gradient, starting at 5°C below the calculated Tm of your primers.

- Extension: 72°C for 1 minute per kb of amplicon.

- Final Extension: 72°C for 5-10 minutes.

Titration of Magnesium Concentration (if problems persist):

Analysis:

- Analyze 5-10 µL of the PCR product by agarose gel electrophoresis to check for product size, specificity, and yield.

The workflow for this optimization process is outlined in the diagram below.

Master Mix Selection Data and Market Trends

Understanding the different types of master mixes available and their market growth can inform your reagent selection and highlight industry trends.

Table 3: Global PCR Master Mix Market Overview (2025-2033 Projections)

| Segment | Key Characteristics | Projected Market Size (2033) | Primary Growth Drivers |

|---|---|---|---|

| Standard PCR Master Mixes | General-purpose, cost-effective; ideal for routine, simple amplicons. | ~$2.8 Billion (Total Market) [21] | Widespread use in basic research and education. |

| Hot-Start PCR Master Mixes | Enhanced specificity; enzyme inactive until high-temp activation. | ~$476 Million (Segment) [22] | Demand for high-specificity in diagnostics and multiplex assays [32] [22]. |

| High-Fidelity PCR Master Mixes | Low error rates (proofreading); essential for cloning and sequencing. | ~$1.2 Billion (Segment) [21] | Growth in personalized medicine, synthetic biology, and biopharma R&D [21] [32]. |

The decision-making process for selecting the right master mix based on template type is summarized below.

Troubleshooting Guides

Guide 1: Resolving Nonspecific Amplification and Primer-Dimer Formation

Problem: Multiple, unexpected bands on the gel or amplification curves, indicating off-target binding and primer-dimer artifacts, especially in assays with high plexity.

Cause Analysis:

- Primer Specificity: Inadequate in silico checks for cross-homology or self-complementarity.

- Annealing Temperature (Ta): Suboptimal Ta leading to promiscuous primer binding.

- Magnesium Concentration: Excess Mg²⁺ can stabilize nonspecific primer-template interactions.

- Primer Concentration: High primer concentrations increase the probability of dimerization.

Solution Steps:

- Re-evaluate Primer Design: Use tools like NCBI BLAST for specificity. Ensure primers have similar melting temperatures (Tm ± 2°C).

- Perform a Temperature Gradient: Optimize the annealing temperature across a range (e.g., 55°C to 65°C).

- Titrate MgCl₂: Test MgCl₂ concentrations from 1.5 mM to 4.0 mM in 0.5 mM increments.

- Optimize Primer Cocktail: Systematically lower individual primer concentrations (from 0.5 µM down to 0.1 µM).

- Use a Hot-Start Polymerase: This prevents enzyme activity during reaction setup, reducing low-temperature artifacts.

- Incorporate Additives: Add Betaine (0.5-1.5 M) or DMSO (1-5%) to reduce secondary structures and improve specificity.

Guide 2: Addressing Uneven or Suppressed Amplification of Multiple Targets

Problem: Significant variation in Cq values (>3 cycles between targets) or complete dropout of one or more targets.

Cause Analysis:

- Primer Competition: Limited reagents (dNTPs, enzyme, cofactors) are being disproportionately consumed by the most efficient primers.

- Amplicon Length Disparity: Shorter amplicons out-compete longer ones.

- Sequence-Dependent Biases: GC-rich targets may amplify poorly compared to AT-rich ones under standard conditions.

- Master Mix Incompatibility: Standard master mixes may not be formulated for high-plex reactions.

Solution Steps:

- Re-balance Primer Ratios: Identify the weakest amplifier and increase its primer concentration relative to the strongest one. This often requires an iterative process.

- Standardize Amplicon Length: Design all amplicons to be within a narrow size range (e.g., 70-150 bp).

- Optimize Master Mix Formulation:

- Increase polymerase concentration (e.g., from 0.025 U/µL to 0.05 U/µL).

- Ensure sufficient dNTP pool (e.g., 400-500 µM of each dNTP).

- Validate with a Commercial Multiplex Master Mix: Use a specialized master mix as a positive control to rule out formulation issues.

Frequently Asked Questions (FAQs)

Q1: What is the maximum number of targets I can reliably multiplex in a single qPCR reaction? A: The practical limit is typically 4-6 plex for standard assays. However, with advanced design and optimization (like data-driven Smart-Plexer approaches), 10-plex and higher is achievable. The limit is dictated by spectral overlap of fluorescent dyes, reagent competition, and instrument detection capabilities.

Q2: How do I select and combine fluorescent dyes for multiplex qPCR? A: Choose dyes with distinct emission spectra to minimize crosstalk. The combination must be compatible with your real-time PCR instrument's optical filters. Common pairs include FAM/HEX/Cy5/ROX. Always perform a dye crosstalk control (single dyes in all channels) to validate the setup.

Q3: My multiplex assay works with a specialized commercial master mix but fails with my in-house formulation. What key components should I re-examine? A: Focus on these components in your in-house master mix optimization, framed within the context of your thesis research:

| Component | Typical Concentration Range (Standard) | Recommended for High-Plex | Function & Rationale for Optimization |

|---|---|---|---|

| Hot-Start DNA Polymerase | 0.02 - 0.025 U/µL | 0.04 - 0.075 U/µL | Catalyzes DNA synthesis. Increased concentration helps maintain processivity across competing targets. |

| MgCl₂ | 1.5 - 3.0 mM | 2.5 - 4.0 mM (Titrate) | Essential cofactor. Critical for primer binding and fidelity; optimal concentration is highly sequence-dependent in multiplex. |

| dNTPs | 200 µM each | 400 - 500 µM each | Building blocks for new DNA strands. Higher concentration prevents depletion in reactions with multiple simultaneous amplifications. |

| PCR Buffer | 1X | 1X (with proprietary enhancers) | Maintains pH and ionic strength. Commercial mixes often contain proprietary stabilizers and enhancers (e.g., trehalose, BSA) that are difficult to replicate. |

| Betaine | 0 M | 0.8 - 1.2 M | Additive. Equalizes the melting temperature of DNA strands by reducing the differential stability of GC vs. AT base pairs, crucial for uniform amplification. |

Q4: What is a data-driven multiplexing approach like "Smart-Plexer," and how does it work? A: Smart-Plexer is a conceptual framework that uses pre-experimental data and computational modeling to predict optimal multiplex assay conditions. Instead of purely empirical "trial-and-error," it involves:

- In silico Prediction: Using software to calculate primer thermodynamics (Tm, ΔG), predict dimerization, and estimate amplification efficiency for each primer pair.

- Monoplex Calibration: Running each primer pair individually to gather empirical Cq and efficiency data.

- Algorithmic Optimization: Inputting the monoplex data and in silico predictions into a model that calculates the ideal primer concentration ratios and master mix composition for the multiplex reaction to achieve balanced Cq values.

Experimental Protocol: Master Mix Optimization for a 5-Plex qPCR Assay

Objective: To systematically optimize an in-house master mix formulation for robust and balanced amplification of five genetic targets.

Materials:

- Template: Genomic DNA (e.g., 10 ng/µL human genomic DNA).

- Primers: Five target-specific primer pairs, resuspended to 100 µM stock.

- Master Mix Components: Hot-Start Taq Polymerase, 10X PCR Buffer, 50 mM MgCl₂, 10 mM dNTP Mix, Molecular Grade H₂O, Betaine (5M stock).

- qPCR Instrument: Any standard real-time PCR cycler.

Methodology:

- Primer Cocktail Preparation: Based on initial monoplex data, create a primer cocktail with unequal concentrations. For example, assign weaker amplifiers (higher Cq) a higher concentration (e.g., 0.4 µM) and strong amplifiers (low Cq) a lower concentration (e.g., 0.1 µM).

- Master Mix Formulation Matrix: Prepare a series of master mixes according to the table below. Keep the primer cocktail and template volume constant.

| Reaction Component | Condition 1 (Standard) | Condition 2 (High Enzyme) | Condition 3 (High dNTP) | Condition 4 (With Betaine) |

|---|---|---|---|---|

| 10X PCR Buffer | 1X | 1X | 1X | 1X |

| MgCl₂ (50 mM) | 3.0 mM | 3.0 mM | 3.0 mM | 3.5 mM |

| dNTP Mix (10 mM) | 0.2 mM each | 0.2 mM each | 0.4 mM each | 0.2 mM each |

| Taq Polymerase | 0.025 U/µL | 0.05 U/µL | 0.025 U/µL | 0.05 U/µL |

| Betaine (5M) | - | - | - | 1.0 M |

| Primer Cocktail | 1X | 1X | 1X | 1X |

| Template DNA | 1X | 1X | 1X | 1X |

| H₂O | To Volume | To Volume | To Volume | To Volume |

- qPCR Run: Aliquot the master mixes into a qPCR plate, run in triplicate. Use a standard thermocycling protocol with a combined annealing/extension step at 60°C for 60 seconds.

- Data Analysis: Compare the Cq values, amplification curves, and endpoint fluorescence for all five targets across the four conditions. The optimal condition is the one with the smallest ΔCq between targets and the highest fluorescence for all.

Visualizations

Diagram 1: Multiplex PCR Troubleshooting Logic

Diagram 2: Data-Driven Smart-Plexer Workflow

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function |

|---|---|

| Hot-Start Taq DNA Polymerase | A modified enzyme inactive at room temperature, preventing non-specific amplification and primer-dimer formation during reaction setup. Essential for complex multiplexing. |

| Multiplex PCR Master Mix (Commercial) | Pre-optimized, proprietary formulations containing enhanced buffer salts, stabilizers, and higher concentrations of polymerase and dNTPs specifically designed for multi-target assays. |

| dNTP Mix | An equimolar solution of the four deoxynucleotides (dATP, dCTP, dGTP, dTTP), the essential building blocks for DNA synthesis. Purity and concentration are critical. |

| MgCl₂ Solution | A magnesium chloride solution used to titrate the final Mg²⁺ concentration in the reaction. Mg²⁺ is a crucial cofactor for polymerase activity and affects primer annealing. |

| PCR Additives (Betaine, DMSO) | Chemical enhancers that reduce the formation of secondary structures in DNA templates, homogenize the melting temperatures of different amplicons, and improve overall assay robustness. |

| Fluorescent Probe/Primer Sets | Hydrolysis probes (e.g., TaqMan) or dual-labeled primers that emit a fluorescent signal upon amplification. Must be spectrally distinct for multiplex detection. |

Optimizing Master Mixes for Reverse Transcription (RT-PCR), qPCR, and dPCR

Within the framework of biomedical PCR assay research, the master mix is not merely a convenience but the biochemical cornerstone of the reaction. It is a pre-mixed, optimized solution containing the core components necessary for the amplification of nucleic acids [33]. The strategic optimization of these master mixes is critical for developing robust, reproducible, and cost-effective diagnostic and research assays in drug development [34] [33]. A poorly optimized master mix can lead to a cascade of experimental failures, including false negatives in clinical diagnostics or irreproducible data in pre-clinical research, thereby compromising the validity of scientific conclusions. The principles of Robust Parameter Design (RPD), which aim to minimize the influence of uncontrollable noise factors by adjusting control factors, are perfectly aligned with master mix optimization [34]. Here, the composition of the master mix represents a set of control factors designed to ensure consistent performance despite variations in sample quality, operator technique, or instrument calibration.

Core Principles of Master Mix Composition and Optimization

Universal Components of a PCR Master Mix

A master mix, whether for standard PCR, qPCR, or RT-PCR, typically contains several key components. Combining these into a single master mix reduces pipetting steps, minimizes contamination, improves consistency across multiple reactions, and saves time [33]. The table below summarizes these essential elements.

Table: Key Components of a Standard PCR Master Mix

| Component | Standard Final Concentration | Function | Optimization Considerations |

|---|---|---|---|

| DNA Polymerase | 0.5–2.5 units/50 µL reaction [31] | Enzymatically synthesizes new DNA strands. | Hot-start versions reduce non-specific amplification; fidelity varies [17]. |

| Buffer | 1X concentration | Provides optimal chemical environment (pH, salts) for polymerase activity. | Buffer composition is often proprietary and polymerase-specific [35]. |

| Magnesium (Mg²⁺) | 1.5–5.0 mM [31] | Essential cofactor for polymerase activity; influences primer annealing and product specificity. | A critical optimization parameter; concentration affects yield and specificity [36] [17]. |

| dNTPs | 200 µM each [31] | Building blocks (dATP, dCTP, dGTP, dTTP) for DNA synthesis. | Unbalanced concentrations increase PCR error rate; quality is paramount [17]. |

| Primers | 0.1–1 µM each [17] | Forward and reverse primers define the target sequence to be amplified. | Concentration must be optimized to balance yield and primer-dimer formation [36] [17]. |

| Stabilizers/Additives | Varies | Enhancers like DMSO, BSA, or Betaine [31]. | Aid in amplifying complex templates (e.g., GC-rich); require careful titration [17]. |

Advanced Master Mix Formulations for Specialized Techniques

Beyond standard PCR, specialized techniques require tailored master mixes.

- Reverse Transcription (RT-PCR) Master Mixes: These contain reverse transcriptase in addition to PCR components for converting RNA into complementary DNA (cDNA) in a one-step protocol. Kits are available that blend a high-fidelity reverse transcriptase with a proofreading enzyme to ensure accurate cDNA synthesis [33].

- Quantitative PCR (qPCR) Master Mixes: These mixes include either a DNA-binding dye like SYBR Green I or are compatible with sequence-specific fluorescent probes (e.g., TaqMan) [33]. They are optimized for speed, sensitivity, and low background fluorescence. Many include a passive reference dye (e.g., ROX) to normalize for well-to-well variation [33].

- High-Fidelity PCR Master Mixes: Designed for applications like cloning, these mixes utilize proofreading DNA polymerases (e.g., Q5, Phusion, KOD) that possess 3'→5' exonuclease activity to correct misincorporated nucleotides, resulting in significantly lower error rates [36] [17]. These often use MgSO₄ instead of MgCl₂ [33].

Table: Comparison of Master Mix Types for Specialized PCR Applications

| Application | Core Specialized Component | Key Function | Example Commercial Mixes |

|---|---|---|---|

| High-Fidelity PCR | Proofreading DNA Polymerase (e.g., Q5, Phusion) | Reduces error rate for cloning and sequencing | High-fidelity PCR Master, KOD Hot Start Master Mix [33] |

| qPCR (Probe-based) | Hot-start Taq, dNTPs, Buffer, Passive Reference Dye (ROX) | Enables target-specific quantification via hydrolysis probes | FastStart TaqMan Probe Master, EagleTaq Universal Master Mix (ROX) [33] |

| qPCR (SYBR Green) | Hot-start Taq, dNTPs, Buffer, SYBR Green I dye | Binds double-stranded DNA for intercalation-based quantification | FastStart SYBR Green Master, KiCqStart SYBR Green qPCR ReadyMix [33] |

| One-Step RT-qPCR | Reverse Transcriptase, PCR Enzyme, dNTPs, Buffer | Combines reverse transcription and qPCR in a single tube | KiCqStart One-Step Probe RT-qPCR ReadyMix [33] |

Figure 1: A systematic workflow for optimizing a PCR master mix, incorporating iterative testing of key variables like annealing temperature and magnesium concentration to achieve a robust and reliable protocol.

The Scientist's Toolkit: Essential Research Reagent Solutions

Successful assay development relies on a suite of trusted reagents and tools. The following table details essential materials for master mix optimization and troubleshooting.

Table: Essential Research Reagent Solutions for Master Mix Optimization

| Reagent / Tool | Function | Example Use-Case |

|---|---|---|

| Hot-Start DNA Polymerase | Polymerase is inactive at room temperature, preventing non-specific priming and primer-dimer formation until the initial denaturation step [17]. | Essential for high-specificity multiplex PCR and routine assays to improve yield of the desired product [33] [17]. |

| GC Enhancer / Betaine | Additives that destabilize secondary structures and reduce the melting temperature of GC-rich DNA, facilitating primer annealing and polymerase progression [31] [17]. | Amplification of difficult, GC-rich templates that would otherwise fail or produce low yield [17]. |

| MgCl₂ / MgSO₄ Stock Solutions | Tunable source of magnesium cofactor. Mg²⁺ concentration is a primary variable for optimizing reaction efficiency and specificity [36] [31]. | Titrated in 0.2-1 mM increments to resolve issues like no product, multiple bands, or smears on a gel [36] [17]. |

| dNTP Mix (Ultrapure) | Provides high-quality, equimolar nucleotides for accurate and efficient DNA synthesis. Impurities or imbalances can reduce yield and increase error rate [17]. | Critical for all PCR applications, especially high-fidelity amplification and long-amplicon PCR. |

| Nuclease-Free Water | Solvent free of RNases and DNases that could degrade reaction components, ensuring reaction integrity. | Used for resuspending primers and bringing all reaction mixes to their final volume. |

| Gradient Thermal Cycler | Instrument that allows testing a range of annealing temperatures across a single block, dramatically speeding up optimization [17]. | Empirically determining the optimal annealing temperature for a new primer set [36]. |

Troubleshooting Guides and FAQs

Low or No Amplification Yield

Q: My PCR reaction has failed, and I see no product or a very faint band on the gel. What are the primary causes in the master mix, and how can I resolve them?

- A: Troubleshooting Low/No Yield

- Problem: Suboptimal Magnesium Concentration.

- Cause: Mg²⁺ is a crucial cofactor for polymerase activity. Insufficient Mg²⁺ can drastically reduce or eliminate amplification [36] [17].

- Solution: Titrate Mg²⁺ concentration in 0.5 mM to 1.0 mM increments across a test range (e.g., 1.0 mM to 4.0 mM) to find the optimum for your specific primer-template system [36] [31].

- Problem: Inactive or Insufficient DNA Polymerase.

- Cause: Enzyme may have been inactivated by improper storage or handling. The amount of polymerase may be insufficient for the specific template or inhibited by sample carryover [17].

- Solution: Ensure fresh aliquots and proper storage. Test a new batch of polymerase. Consider increasing the amount of polymerase or using a master mix with high processivity and inhibitor tolerance [17].

- Problem: Poor Primer Design or Quality.

- Cause: Primers with secondary structures (hairpins), self-complementarity (primer dimers), or miscalculated melting temperatures (Tm) will not anneal efficiently [31].

- Solution: Verify primer sequence and design using software (e.g., NCBI Primer-BLAST). Resuspend primers properly, avoid freeze-thaw cycles by aliquoting, and confirm concentration spectrophotometrically [35] [31]. Optimize primer concentration (typically 0.1-1 µM) [17].

- Problem: Inhibitors in the Reaction.

- Cause: Residual salts, phenol, EDTA, or proteins from the template purification process can inhibit DNA polymerases [17].

- Solution: Re-purify the template DNA, perform an ethanol precipitation, or use a DNA cleanup kit. Consider diluting the template or using a polymerase known for high tolerance to inhibitors [17].

- Problem: Suboptimal Magnesium Concentration.

Non-Specific Amplification and Multiple Bands

Q: My reaction produces multiple incorrect bands or a smear instead of a single, specific product. How can I adjust the master mix to improve specificity?

- A: Troubleshooting Non-Specific Amplification

- Problem: Annealing Temperature is Too Low.

- Cause: Low temperature allows primers to bind to non-target sequences with partial complementarity [17].

- Solution: Increase the annealing temperature in 1-2°C increments. Use a gradient thermal cycler to empirically determine the optimal temperature, which is typically 3-5°C below the primer Tm [36] [17].

- Problem: Excess Magnesium or DNA Polymerase.

- Problem: Non-Hot-Start Polymerase Activity.

- Cause: Standard polymerases have activity at room temperature, leading to primer-dimer formation and mispriming during reaction setup [17].

- Solution: Switch to a hot-start DNA polymerase, which is inactive until a high-temperature activation step. Alternatively, set up reactions on ice and use pre-heated thermocyclers [17].

- Problem: Too Much Template or Primer.

- Problem: Annealing Temperature is Too Low.

Reducing Error Rate and Improving Fidelity for Cloning

Q: I am generating PCR products for cloning, but my sequencing results show a high number of mutations. How can I optimize my master mix for high fidelity?

- A: Troubleshooting Low Fidelity

- Problem: Using a Low-Fidelity DNA Polymerase.

- Problem: Unbalanced dNTP Concentrations.

- Cause: If the concentrations of dATP, dCTP, dGTP, and dTTP are not equimolar, the polymerase is more likely to incorporate an incorrect nucleotide [17].

- Solution: Always use a high-quality, pre-mixed dNTP solution with each nucleotide at a standardized concentration (e.g., 2.5 mM each for a 10 mM total dNTP mix) [17].

- Problem: Excessive Cycle Number.

- Cause: Each PCR cycle presents an opportunity for errors; thus, a high number of cycles amplifies any early errors exponentially [17].

- Solution: Use the minimum number of cycles necessary to produce sufficient yield for your downstream application. Increase the amount of input DNA if possible to reduce the required cycles [17].

Figure 2: A logical troubleshooting guide for common PCR issues. This decision-path map helps researchers systematically identify and address the most probable master mix-related causes of amplification failure, non-specificity, or low fidelity.

Detailed Experimental Protocols for Optimization

Protocol 1: Optimizing Magnesium Concentration and Annealing Temperature

Objective: To empirically determine the optimal Mg²⁺ concentration and annealing temperature for a new primer set using a single 96-well plate.

Background: Both Mg²⁺ and annealing temperature (Tₐ) are interdependent factors critical for specificity and yield. Mg²⁺ stabilizes DNA duplexes and is a necessary polymerase cofactor, while the Tₐ determines the stringency of primer binding [36] [31] [17].

Materials:

- 10X PCR Buffer (without MgCl₂)

- 50 mM MgCl₂ stock solution

- Custom primer set (e.g., 20 µM each)

- dNTP mix (10 mM)

- DNA template (e.g., 10 ng/µL)

- Nuclease-free water

- Hot-start DNA polymerase

- Gradient thermal cycler

Method:

- Prepare a Master Mix for 48 reactions (allowing for duplicates) containing per reaction: 1X PCR Buffer, 200 µM dNTPs, 0.5 µM of each primer, 1 unit of hot-start DNA polymerase, and nuclease-free water. Do not add Mg²⁺ or template yet.

- Aliquot the master mix into 6 sterile 1.5 mL tubes.

- Spike each tube with a different volume of 50 mM MgCl₂ to create a Mg²⁺ concentration series (e.g., 1.0 mM, 1.5 mM, 2.0 mM, 2.5 mM, 3.0 mM, 4.0 mM). Mix thoroughly.

- Add a constant volume of DNA template to each Mg²⁺ tube and mix.

- Dispense the contents of each Mg²⁺ tube into a single row of an 8-well PCR strip (or a column of a 96-well plate), preparing enough for duplicate reactions.

- Run the PCR using a gradient thermal cycler, setting the annealing temperature to span a range (e.g., 55°C to 65°C) across the block.

- Analyze the results via agarose gel electrophoresis. The well showing a single, intense band of the correct size at the highest Tₐ and narrowest Mg²⁺ range indicates the optimal conditions.

Protocol 2: Systematic Assay Validation Using a Robust Optimization Framework

Objective: To validate a master mix protocol ensuring it is both cost-effective and robust to normal experimental variations, aligning with Robust Parameter Design principles [34].

Background: A robust protocol minimizes the influence of "noise factors" (e.g., minor pipetting errors, tube lot variations, thermocycler calibration) by optimizing "control factors" (master mix components) [34]. This is formalized in a stochastic optimization problem: minimize cost g₀(x) = cᵀx subject to the constraint that protocol performance g(x,z,w,e) ≥ t, where x represents control factors and z,w,e represent various noise factors [34].

Materials:

- Optimized master mix from Protocol 1

- Multiple lots of nuclease-free water

- Different brands of PCR tubes

- Two different thermal cyclers

- Technical operators of varying experience levels

Method:

- Define Control and Noise Factors: Control factor (x) is the master mix formulation. Noise factors (z,w) can include different reagent lots, tube types, instruments, and operators.

- Experimental Design: Prepare a large batch of the optimized master mix. Set up multiple identical reactions where these noise factors are deliberately varied according to a structured design.

- Execution: Run the PCR amplification with all samples.

- Data Analysis: Quantify the output (e.g., qPCR Cq values, band intensity). Use a mixed effects model to partition the variance and estimate the protocol's sensitivity to the different noise factors [34].

- Validation: The protocol is considered robust if the performance (e.g., Cq value or yield) consistently remains above a pre-defined threshold (t) across all noise conditions, with minimal variance. This ensures reliability in a high-throughput production environment [34].

The optimization of Polymerase Chain Reaction (PCR) master mixes is a critical step in ensuring the accuracy, sensitivity, and reliability of biomedical PCR assays in research and drug development. Even with perfectly designed primers and optimized cycling conditions, many PCR templates present challenges that standard protocols cannot overcome. GC-rich regions, complex secondary structures, and the presence of PCR inhibitors commonly encountered with clinical samples can lead to amplification failure, reduced yield, or non-specific products. Incorporating specific additives such as Dimethyl sulfoxide (DMSO), Bovine Serum Albumin (BSA), and Betaine into PCR master mixes provides a powerful strategy to overcome these hurdles. This guide provides researchers with detailed, practical information on how and when to use these key additives to enhance amplification efficiency for even the most challenging targets, framed within the broader context of master mix optimization for biomedical research.

FAQ: Troubleshooting Common PCR Problems with Additives