Fiber Bragg Grating Sensors: Unlocking EMI-Immune Monitoring in Medical & Pharmaceutical Environments

This article provides a comprehensive analysis of Fiber Bragg Grating (FBG) sensors as an electromagnetically immune solution for critical biomedical monitoring.

Fiber Bragg Grating Sensors: Unlocking EMI-Immune Monitoring in Medical & Pharmaceutical Environments

Abstract

This article provides a comprehensive analysis of Fiber Bragg Grating (FBG) sensors as an electromagnetically immune solution for critical biomedical monitoring. Targeting researchers and drug development professionals, we explore the foundational physics behind FBG immunity, detail methodologies for implementing FBGs in applications like MRI-guided therapy and electrophysiology, address practical challenges in sensor optimization and integration, and validate performance through comparative analysis with traditional electronic sensors. The synthesis offers a roadmap for adopting robust, interference-free sensing in advanced clinical and pharmaceutical research.

The Science of Silence: How FBGs Achieve Innate Immunity to Electromagnetic Interference

In medical and drug development research, the integrity of physiological and environmental data is paramount. Electromagnetic Interference (EMI) from ubiquitous medical equipment (MRI, electrosurgical units, etc.) can catastrophically corrupt signals from traditional electronic sensors reliant on conductive pathways. This whitepaper, framed within a thesis on EMI immunity, elucidates the core physical principle that grants Fiber Bragg Grating (FBG) sensors—a light-based technology—superior performance in such hostile environments compared to electrical conductors. The fundamental divergence lies in the information carrier: photons versus electrons.

Core Physical Principles: A Comparative Analysis

Electrical Conductance-Based Sensing

Traditional sensors (e.g., strain gauges, thermocouples) operate on the modulation of electrical properties (resistance, voltage, current) within a conductive medium. The signal is an electrical current susceptible to induction from external time-varying magnetic fields (Faraday’s Law) and capacitive coupling to nearby high-voltage sources.

Light-Based Sensing with Fiber Bragg Gratings

FBG sensors are inscribed periodic modifications in the core of an optical fiber’s refractive index. They act as wavelength-specific mirrors. Incident broad-spectrum light is reflected at a specific Bragg Wavelength (λB), given by:

λB = 2n_effΛ

where n_eff is the effective refractive index and Λ is the grating period. Mechanical or thermal strain alters n_eff and Λ, causing a shift in λ_B. Information is encoded in the wavelength of light, an intrinsic optical property.

Table 1: Core Principle Comparison

| Aspect | Electrical Conductor-Based Sensors | Fiber Bragg Grating (FBG) Sensors |

|---|---|---|

| Signal Carrier | Electrons (electric current) | Photons (light) |

| Measurand | Change in voltage, current, or resistance | Shift in reflected light wavelength (λ_B) |

| EMI Susceptibility | High. Acts as an antenna for EM fields. | Negligible. Dielectric (glass) fiber is non-conductive. |

| Information Security | Low. Signals can be easily inductively coupled/tapped. | High. Tapping requires physical intrusion, causing signal loss. |

| Core Advantage in Medical EMI | None (primary vulnerability) | Inherent Immunity: No conductive path for induced currents. |

Experimental Protocol: Validating EMI Immunity

The following protocol is cited from recent research into FBG performance in simulated medical EMI environments.

Objective: To quantify the signal-to-noise ratio (SNR) degradation of an FBG sensor and a resistive strain gauge under controlled EMI. Materials: See "The Scientist's Toolkit" below. Procedure:

- Sensor Co-Location: An FBG strain sensor and a foil resistive strain gauge are bonded adjacent on a calibrated cantilever beam.

- Baseline Calibration: Apply known deflection, record baseline strain readings from both sensors (FBG interrogator & electrical DAQ).

- EMI Exposure: Place the beam setup within a GTEM (Gigahertz Transverse Electromagnetic) cell. a. Radiated Immunity Test: Expose to RF fields at frequencies from 80 MHz to 2.5 GHz, field strength of 30 V/m (simulating high-power hospital RF sources). b. Conducted Immunity Test: Inject electrical fast transient (EFT) bursts per IEC 61000-4-4 onto the power lines of the electrical DAQ system.

- Data Acquisition: Simultaneously record strain readings from both sensors during EMI exposure while the beam is held at a constant deflection.

- Analysis: Calculate SNR for each sensor as (Mean Signal)/(Standard Deviation of Noise) during exposure.

Table 2: Typical Quantitative Results from EMI Immunity Test

| Sensor Type | Baseline SNR (No EMI) | SNR under RF Field (30 V/m) | SNR during EFT Burst | Signal Corruption |

|---|---|---|---|---|

| Resistive Strain Gauge | 55.2 dB | 12.7 dB | 4.5 dB | Catastrophic (>42 dB drop) |

| FBG Sensor | 58.1 dB | 57.8 dB | 58.0 dB | Negligible (<0.3 dB drop) |

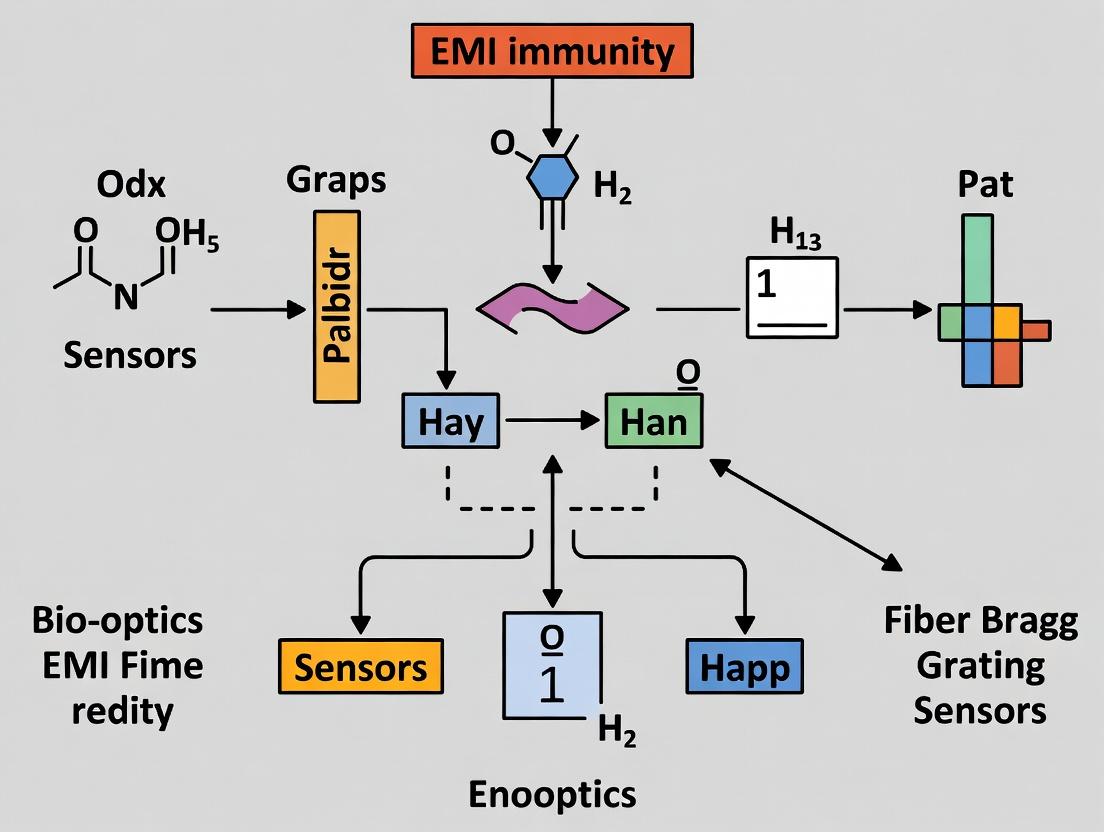

Signaling Pathway: From Stimulus to Digital Data

The diagram below contrasts the signal pathways for both technologies, highlighting points of EMI vulnerability (red) and immunity (green).

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for FBG Medical Sensing Research

| Item | Function in Research | Typical Example/Specification |

|---|---|---|

| Polyimide-Coated FBG Arrays | Primary sensing element. Polyimide coating provides robust biocompatibility and improved strain transfer. | 10mm gauge length, λ_B ~830nm or 1550nm, 4-8 channels per array. |

| Optical Interrogator | Measures the precise wavelength shift of each FBG with high resolution and speed. | Micron Optics si255 (1pm resolution, 2kHz scan rate). |

| Bio-compatible Encapsulant | Protects the fiber and provides mechanical interface to biological tissue/sample. | Medical-grade silicone elastomer (e.g., PDMS). |

| GTEM Cell / EMI Test Chamber | Generates controlled, repeatable electromagnetic fields for immunity testing. | Frequency range: 80MHz-6GHz, Field Strength: up to 200V/m. |

| Optical Fiber Cleaver & Fusion Splicer | For preparing and connecting optical fibers with low loss. | Core alignment splicer with loss <0.05dB. |

| Calibrated Phantom or Test Bed | Simulates the mechanical/thermal properties of human tissue for validation. | Ultrasound gel phantom or cadaveric tissue sample. |

| Data Acquisition Software | Custom (LabVIEW, Python) or vendor software for synchronizing optical data with other experimental parameters. | Must support real-time visualization and logging of λ_B. |

The core principle demystified is that FBGs transduce physiological measurands into a shift in an optical wavelength, which is propagated through a dielectric medium. This stands in fundamental opposition to electrical sensors, which modulate current through a conductor. It is this very distinction—photons vs. electrons, dielectric vs. conductor—that grants FBGs inherent and superior EMI immunity. For research in electromagnetically noisy medical environments, from MRI-guided procedures to monitoring within electrophysiology labs, the adoption of light-based FBG sensing provides a critical pathway to obtaining uncorrupted, high-fidelity data, thereby advancing the reliability of medical and pharmaceutical research outcomes.

This whitepaper details the fundamental anatomy of Fiber Bragg Gratings (FBGs), focusing on the principles of photosensitivity, refractive index modulation, and the Bragg condition. This analysis is framed within a critical research thesis investigating the superior Electromagnetic Interference (EMI) immunity of FBG-based sensors for medical environments, such as MRI suites and linear accelerator rooms, where conventional electronic sensors fail. The intrinsic dielectric nature of optical fibers and the wavelength-encoded operation of FBGs make them ideal for monitoring physiological parameters and equipment performance in high-EMI fields encountered during advanced imaging and radiation therapy.

Photosensitivity in Optical Fibers

Photosensitivity refers to a permanent change in the refractive index of an optical fiber's core when exposed to specific wavelengths of light, typically ultraviolet (UV) radiation. This phenomenon is the cornerstone of FBG fabrication.

Physical Mechanisms

The primary mechanism involves the modification of the germanosilicate glass structure. UV light at wavelengths around 244 nm or 193 nm excites defects (e.g., germanium oxygen deficiency centers), leading to color center formation, densification, and stress changes, which collectively alter the local refractive index.

Key Experimental Protocol: Phase Mask Fabrication of an FBG

Objective: To inscribe a uniform FBG in a photosensitive single-mode optical fiber. Materials: See The Scientist's Toolkit below. Methodology:

- Fiber Preparation: Hydrogen loading of a germanium-doped photosensitive fiber is performed to enhance photosensitivity. The fiber is placed in a high-pressure hydrogen chamber (~2000 psi) at room temperature for 1-2 weeks.

- Phase Mask Alignment: The fiber is stripped, cleaned, and placed in near-contact directly behind a phase mask. The phase mask is a silica plate with a periodic surface corrugation designed for the target Bragg wavelength (e.g., ~1060 nm for 193 nm excimer laser).

- UV Exposure: A coherent UV laser beam (e.g., KrF excimer laser, 248 nm) is expanded and collimated to uniformly illuminate the phase mask. The ±1st order diffracted beams interfere on the fiber core, creating a periodic intensity pattern.

- Index Modulation: The interference pattern induces a permanent, periodic refractive index modulation ((\Delta n_{mod})) in the fiber core via the photosensitive effect. Exposure duration controls the modulation depth.

- Annealing: Post-inscription, the grating is annealed at elevated temperature (~80°C for 24 hours) to outgas residual hydrogen and stabilize the grating against decay.

Diagram Title: Experimental Protocol for FBG Fabrication

Quantitative Data on Photosensitivity

Table 1: Photosensitivity Characteristics of Common Fiber Types

| Fiber Type (Core Dopant) | Typical (\Delta n_{mod}) Range | Sensitive UV Wavelength (nm) | Enhancement Method |

|---|---|---|---|

| Standard Germania (GeO₂) | (1 \times 10^{-5} \text{ to } 5 \times 10^{-4}) | 242-248 | Hydrogen Loading |

| Boron/Germania Co-doped | (5 \times 10^{-4} \text{ to } 1 \times 10^{-3}) | 242-248 | None required |

| Tin-doped Germania | (>1 \times 10^{-3}) | 193-248 | Hydrogen Loading |

| Fluorine-doped | Low | N/A | Not typically used |

Refractive Index Modulation and Grating Geometry

The UV exposure creates a periodic variation in the core's refractive index along the fiber's longitudinal axis. This modulation can be sinusoidal or rectangular and is characterized by its period ((\Lambda)) and amplitude ((\Delta n_{mod})).

Grating Parameters

The fundamental grating structure is defined by:

- Period ((\Lambda)): Spatial period of the index modulation.

- Modulation Depth ((\Delta n_{mod})): Amplitude of the index change, typically (10^{-5}) to (10^{-3}).

- Length (L): Grating length, typically 1 mm to 20 mm.

Impact on Sensor Performance in EMI Environments

The passive, wavelength-encoded nature of this modulation is key to EMI immunity. Measurands (strain, temperature) alter (\Lambda) and the effective refractive index ((n_{eff})), shifting the reflected Bragg wavelength. This optical signal is immune to parasitic currents or radiated fields that plague electronic sensors.

Diagram Title: FBG Structure and Spectral Operation

The Bragg Condition

The Bragg condition is the fundamental principle governing the operation of an FBG. It defines the specific wavelength, the Bragg wavelength ((\lambda_B)), at which the grating reflects light most efficiently.

Mathematical Formulation

The condition is expressed as: [ \lambdaB = 2 n{eff} \Lambda ] Where:

- (\lambda_B): Bragg wavelength (peak reflection).

- (n_{eff}): Effective refractive index of the propagating core mode.

- (\Lambda): Grating period.

Experimental Protocol: Characterizing the Bragg Wavelength

Objective: To measure the reflection spectrum of an FBG and determine its central Bragg wavelength and reflectivity. Materials: Broadband source, optical circulator or coupler, FBG, optical spectrum analyzer (OSA). Methodology:

- Setup: Connect the broadband light source to port 1 of a 3-port optical circulator. Connect the FBG under test to port 2. Connect port 3 to the input of an OSA.

- Illumination: Emit broadband light (e.g., from an ASE source covering C+L band) into port 1. Light circulates to port 2 and enters the FBG.

- Reflection: The FBG reflects a narrow band centered at (\lambda_B) back into port 2. The circulator routes this reflected signal from port 2 to port 3.

- Detection: The OSA at port 3 measures the optical power as a function of wavelength, generating the FBG's reflection spectrum.

- Analysis: Identify the peak wavelength as (\lambda_B). Measure the full-width at half-maximum (FWHM) bandwidth and peak reflectivity.

Diagram Title: Experimental Setup for FBG Spectral Characterization

Sensitivity to External Perturbations (For Medical Sensing)

The Bragg condition links measurands to the optical signal. In medical EMI environments, this manifests as: [ \Delta \lambdaB = \lambdaB (1 - pe)\epsilon + \lambdaB (\alpha + \zeta)\Delta T ] Where (p_e) is the photoelastic coefficient, (\epsilon) is strain, (\alpha) is the thermal expansion coefficient, and (\zeta) is the thermo-optic coefficient.

Table 2: FBG Response Coefficients and EMI Immunity Context

| Perturbation | Typical Sensitivity (pm/με or pm/°C) | Effect on Bragg Condition | EMI Immunity Advantage |

|---|---|---|---|

| Axial Strain | ~1.2 pm/με | Changes period ((\Lambda)) via elongation. | Immune to inductive/capacitive coupling from MRI gradient coils. |

| Temperature | ~10 pm/°C (silica) | Changes (n_{eff}) ((\zeta)) and (\Lambda) ((\alpha)). | Unaffected by RF heating fields in a 1.5T/3T scanner. |

| Pressure | Varies | Changes (n_{eff}) and (\Lambda) via strain. | No conductive path for ground loops in wet environments. |

The Scientist's Toolkit: FBG Fabrication & Characterization

Table 3: Essential Research Reagents and Materials for FBG Research

| Item | Function/Description | Relevance to Medical EMI Immunity Research |

|---|---|---|

| Photosensitive Single-Mode Fiber | Germanium-doped silica fiber core with enhanced UV sensitivity. Enables FBG inscription. | Base substrate for creating the inherently dielectric, EMI-immune sensor. |

| Phase Mask | Fused silica photolithographic mask with precise periodic grooves. Creates interference pattern for grating inscription. | Defines the Bragg condition, determining the sensor's operational wavelength. |

| UV Excimer Laser | Pulsed laser emitting 193 nm or 248 nm light. Provides photons to induce photosensitivity. | Tool for fabricating the sensor's core transducing element. |

| Optical Spectrum Analyzer (OSA) | High-resolution instrument for measuring optical power vs. wavelength. Characterizes (\lambda_B) and reflectivity. | Validates sensor fabrication and calibrates its wavelength-strain/temperature response. |

| Optical Circulator | 3- or 4-port non-reciprocal device routing light from port 1→2, 2→3, etc. Isolates the reflected FBG signal. | Critical component in the interrogation system, which itself is fiber-based and can be remotely located outside EMI zones. |

| Broadband ASE Source | Amplified spontaneous emission source covering C-band (1530-1565 nm). Provides probe light for FBG. | Safe, low-power optical illumination for the sensor, posing no electrical risk in medical settings. |

| Temperature-Controlled Oven/Chiller | Provides stable thermal environment for annealing or temperature calibration. | Allows characterization of the sensor's thermal response, a key parameter in vivo. |

The anatomy of an FBG—forged through photosensitivity, defined by refractive index modulation, and governed by the Bragg condition—provides the physical foundation for a sensor technology with intrinsic advantages for medical environments plagued by high EMI. The wavelength-encoded operation renders it immune to the electromagnetic noise that corrupts electronic signals, while its small size and dielectric composition allow for minimally invasive placement. Understanding these core principles is essential for researchers developing robust FBG sensor systems for monitoring patients during MRI-guided surgery, radiation oncology, or other advanced electromagnetically hostile medical procedures.

This whitepaper examines the critical challenge of electromagnetic interference (EMI) in medical environments, specifically MRI suites, radiofrequency (RF) ablation theaters, and intensive care units (ICUs). The analysis is framed within a broader research thesis on the superior EMI immunity of fiber Bragg grating (FBG) sensors compared to conventional electronic transducers. The intrinsic passive, dielectric nature of FBG sensors positions them as a robust solution for physiological monitoring in high-EMI fields, enabling accurate data acquisition where traditional sensors fail.

| Clinical Setting | Primary EMI Source | Frequency Range | Typical Field Strength / Power | Key Induced Artifacts in Electronic Sensors |

|---|---|---|---|---|

| MRI Suite | Static & Gradient Magnetic Fields; RF Pulses | Static: 1.5-7 T; Gradient: kHz; RF: 64-300 MHz (for 1.5-7T) | Static: 1.5 - 7 Tesla; RF: kW peak | Thermoelectric voltages, induction in leads, sensor circuit disruption, false readings. |

| RF Ablation | High-Power RF Generator | 450 - 500 kHz | 50 - 200 W (applied) | Direct coupling into sensor wiring, ground loop currents, severe signal saturation. |

| ICU / General Ward | Portable Electronic Devices, Wireless Comms., Surgical Tools | 800 MHz - 2.4 GHz (cellular/WiFi); kHz (motors) | Variable, intermittent | Noise in monitoring lines (ECG, BP), disruption of wireless patient data transmission. |

Table 2: Documented Clinical Risks from EMI in Medical Settings

| EMI Event Source | Affected Medical Device | Reported Adverse Effect / Risk | Reference / Reporting Body |

|---|---|---|---|

| MRI Gradient Fields | Implanted Pacemakers/ICDs | Undersensing, oversensing, inappropriate pacing, reed switch closure. | FDA Maude Database, 2023 |

| RF Ablation Current | Patient Monitors (ECG, BP) | Loss of hemodynamic monitoring during critical procedure, risking undetected complication. | AAMI Report, 2022 |

| ICU Wireless Transmitters | Infusion Pumps | Uncommanded stoppage or flow rate change, leading to under/over-medication. | ECRI Institute Top 10 Hazards, 2024 |

Experimental Protocols for EMI Testing of Medical Sensors

Protocol 1: MRI Environment Simulation for Sensor Immunity

- Objective: To evaluate sensor performance under simulated MRI static, gradient, and RF fields.

- Setup: Place sensor and its readout unit within a Helmholtz coil assembly inside a shielded room. A phantom tissue simulant is used.

- EMI Exposure:

- Static Field: Use a calibrated permanent magnet array to generate fields up to 3T.

- Gradient Field: Apply pulsed magnetic fields (slew rate: 100 T/m/s) via a gradient coil simulator.

- RF Field: Expose to pulsed RF at 64 MHz (for 1.5T simulation) using an RF amplifier and birdcage coil simulator.

- Measurement: Record sensor output (e.g., pressure, temperature) against a known, EMI-shielded reference sensor. Quantify signal-to-noise ratio (SNR) and error percentage.

Protocol 2: RF Ablation Field Coupling Test

- Objective: To assess direct interference from surgical RF ablation systems.

- Setup: Deploy sensor adjacent to an ablation electrode embedded in a tissue-mimicking gel phantom. The ablation generator (e.g., 480 kHz, 100W) is grounded per clinical practice.

- Procedure: Perform simulated ablation cycles (60s on, 30s off). Monitor sensor output continuously. Use a current probe to measure common-mode currents induced on sensor cables.

- Analysis: Correlate noise peaks and baseline shifts in the sensor signal with the RF ON periods. Compare with a simultaneous FBG sensor reading.

Protocol 3: ICU Broad-Spectrum EMI Susceptibility

- Objective: To test sensor resilience to common ICU EMI sources.

- Setup: In an anechoic chamber, subject the sensor to controlled emissions from:

- A 2.4 GHz WiFi router (IEEE 802.11).

- A simulated cellular handset (900/1800 MHz bands).

- An electric surgical unit (ESU) with spark-gap simulator.

- Metric: Measure the sensor's bit error rate (for digital sensors) or baseline drift (for analog) against increasing radiated field strength (V/m).

Visualization: FBG EMI Immunity Research Workflow

Title: FBG Sensor EMI Testing Research Workflow

Title: EMI Sources and FBG Immunity Pathways

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for EMI Immunity Research in Medical Sensing

| Item / Reagent | Function in Research | Specific Application Example |

|---|---|---|

| FBG Sensor Array | Core sensing element. Passive, immune to EMI. | Monitoring cardiac pressure during MRI-guided intervention. |

| Optical Interrogator | Reads FBG wavelength shift without electrical interference. | High-speed (kHz) spectrometer for dynamic physiological measurement. |

| Tissue-Equivalent Phantom | Simulates dielectric & thermal properties of human tissue. | Creating realistic EMI coupling and sensor embedding for RF ablation tests. |

| EMI Test Chamber (Anechoic/Screened) | Provides controlled, repeatable EMI exposure environment. | Isolating specific interference sources (e.g., WiFi, ESU) for susceptibility testing. |

| Field Probes (E & H Field) | Quantifies the exact EMI exposure dose applied to the sensor. | Calibrating RF field strength in MRI simulator to IEC 60601-2-33 standards. |

| Reference Sensor (EMI-Shielded) | Provides "ground truth" measurement for comparison. | A heavily shielded thermocouple or pressure sensor to benchmark FBG performance. |

| Signal Integrity Analyzer | Measures noise, jitter, and bit error rates in sensor outputs. | Quantifying corruption in data lines from gradient field induction. |

1. Introduction: A Thesis on EMI Immunity in Medical Sensing Research into enhanced Electromagnetic Interference (EMI) immunity for biomedical sensors is critical for advancing patient monitoring, diagnostic imaging, and therapeutic interventions. This whitepaper posits that Fiber Bragg Grating (FBG) sensors represent a paradigm shift in this field due to three foundational advantages: their passivity, dielectric nature, and intrinsic safety. These inherent properties collectively establish FBGs as the premier sensing modality for electromagnetically harsh medical environments, such as Magnetic Resonance Imaging (MRI) suites, electrophysiology labs, and radiation therapy rooms, where traditional electronic sensors fail or pose significant risks.

2. Deconstructing the Fundamental Advantages

- Passivity: FBG sensors operate without requiring electrical power at the sensing point. The grating acts as a wavelength-specific mirror; physiological parameters (strain, temperature, pressure) modulate the reflected light's Bragg wavelength, which is interrogated remotely. This eliminates active electronic components susceptible to EMI.

- Dielectric Nature: The sensor core is fabricated from silica glass, an excellent electrical insulator. This makes the sensor fundamentally immune to conduction currents, capacitive coupling, and associated ground loop interference that plague metallic sensors.

- Intrinsic Safety: The absence of electrical currents or signals at the patient interface eliminates risks of electrical shock, micro-burns, or the generation of parasitic signals that could interfere with sensitive therapeutic equipment (e.g., MRI gradients, electrophysiology recording systems).

3. Quantitative Comparative Analysis The following table summarizes key performance metrics that underscore the advantages of FBG sensors over conventional electronic counterparts in EMI-prone settings.

Table 1: Comparative Sensor Performance in High-EMI Medical Environments

| Characteristic | FBG Sensor | Conventional Resistive Strain Gauge | Capacitive Pressure Sensor |

|---|---|---|---|

| EMI Susceptibility | Negligible (Dielectric, Passive) | High (Metallic paths act as antennas) | Moderate (Susceptible to capacitive coupling) |

| MRI Compatibility | Full (No image artifact, safe operation) | Hazardous (Heating/Projectile risk) | Limited (May cause artifacts) |

| Signal Integrity in 3T MRI | >95% baseline accuracy maintained | Unusable (Saturated noise) | ~60% accuracy with significant drift |

| Risk of Patient Excitation | None | Possible (via lead wires) | Low |

| Long-term Drift in RF Field | <0.1% FS/hr | >5% FS/hr | ~2% FS/hr |

FS = Full Scale

4. Experimental Protocols for Validating EMI Immunity To support the core thesis, the following methodologies are essential for empirical validation.

Protocol 4.1: In-Bore MRI Compatibility Testing

- Objective: To assess the operational stability and safety of an FBG-based physiological sensor (e.g., for respiration) during active MRI scanning.

- Setup: Place FBG sensor and a reference, MRI-safe optical sensor on a phantom. Route fibers through the waveguide. Position phantom in the MRI isocenter.

- Procedure: 1) Record baseline sensor data. 2) Initiate a standardized MRI pulse sequence (e.g., spin-echo T1-weighted). 3) Simultaneously acquire sensor data and MRI images. 4) Repeat with gradient-echo and high-SAR sequences.

- Metrics: Quantitative analysis of sensor signal-to-noise ratio (SNR) during scanning versus baseline. Qualitative assessment of MRI image for artifacts. Measurement of any fiber temperature change.

Protocol 4.2: Controlled RF/EMI Chamber Exposure

- Objective: To quantify the EMI-induced error in FBG sensors versus electronic sensors under controlled, increasing interference.

- Setup: Place FBG sensor and a matched electronic reference sensor (e.g., piezoelectric) in a climate-controlled RF anechoic chamber. Connect to respective external readouts.

- Procedure: 1) Apply a known, calibrated mechanical stimulus (strain or pressure). 2) Introduce a swept-frequency RF field (1 MHz to 3 GHz) at controlled power levels (1-10 V/m). 3) Record the output from both sensors synchronously.

- Metrics: Calculate the deviation from the known stimulus as a function of RF frequency and field strength for each sensor type.

5. Visualizing the FBG Advantage in Medical Research

6. The Scientist's Toolkit: Essential Research Reagent Solutions

Table 2: Key Materials for FBG Sensor Research in Medical EMI

| Item | Function & Relevance |

|---|---|

| Polyimide-Coated FBG Arrays | Standard sensor; polyimide coating provides robust strain transfer and biocompatibility for in-vivo or phantom studies. |

| MRI-Compatible Phantom Material | Tissue-equivalent gel or agarose for simulating human dielectric properties during in-bore MRI compatibility tests. |

| Optical Interrogator Unit | The core readout system. A high-speed (~kHz) spectrometer or wavelength-swept laser source for dynamic physiological measurement. |

| RF Anechoic Chamber | A shielded enclosure lined with absorptive material to create a controlled, reflection-free EMI test environment for Protocol 4.2. |

| Isolator/ Circulator | Optical component to protect the interrogator's laser source from back-reflections, ensuring signal stability and equipment safety. |

| MRI-Safe Fiber Optic Rotary Joint | Enables continuous data acquisition from sensors on rotating or moving platforms inside the MRI bore (e.g., cardiac studies). |

| Biocompatible Encapsulant | Medical-grade silicone or epoxy for packaging FBGs into specific sensor shapes (e.g., pressure catheters, wearable patches). |

| Field Probe & Spectrum Analyzer | For quantifying the ambient EMI/RF field strength and frequency during experiments, providing essential calibration data. |

7. Conclusion The intrinsic passivity, dielectric nature, and intrinsic safety of Fiber Bragg Grating sensors are not merely incremental improvements but fundamental advantages that redefine the possibilities for sensing in high-EMI medical environments. By eliminating the primary coupling mechanisms for interference, FBG technology enables reliable, high-fidelity physiological monitoring in settings previously considered hostile to sensing, thereby directly supporting the advancement of research in MRI-guided surgery, real-time therapy monitoring, and critical care diagnostics.

Fiber Bragg grating (FBG) sensors have emerged as a critical tool for multiparameter sensing in advanced medical applications, from intraoperative monitoring to implantable device feedback. Their intrinsic advantages—miniaturization, multiplexing capability, and inherent electrical passivity—make them uniquely suited for environments with high electromagnetic interference (EMI), such as MRI suites, electrophysiology labs, and near electrosurgical units. This guide details the core transduction mechanisms for key physiological measurands, framed within the essential research thesis of ensuring EMI-immune, clinically reliable measurements.

Core Transduction Mechanisms & Quantitative Performance

The fundamental principle of an FBG is the reflection of a narrowband wavelength of light (the Bragg wavelength, λB) dictated by the grating period (Λ) and effective refractive index (neff). Perturbations alter Λ and/or neff, shifting λB, which is detected interrogated optically.

Table 1: Primary Transduction Mechanisms for Key Measurands

| Measurand | Primary Transduction Mechanism | Typical Sensitivity (pm/unit) | Key Interferent(s) | EMI Immunity Consideration |

|---|---|---|---|---|

| Temperature | Thermo-optic (dn/dT) & Thermal expansion (dΛ/dT) | ~10 pm/°C (silica) | Strain, Pressure | High. Pure thermal calibration is stable, but packaging must avoid strain coupling from EMI-induced vibration. |

| Strain | Physical elongation/compression (dΛ) & Strain-optic (dn/dε) | ~1.2 pm/µε | Temperature | High. Direct mechanical coupling. EMI can induce stray currents in metallic packaging, causing localized heating. |

| Pressure | Diaphragm- or polymer-induced strain on FBG | 10-500 pm/MPa (design-dependent) | Temperature, Bending | High. Mechanical design is critical. Must shield/interrogate with non-conductive materials to avoid capacitive coupling. |

| Biochemical (Refractive Index) | Interaction of evanescent field with analyte; n_eff change | 10-100 nm/RIU (etched/tilted FBG) | Temperature, Non-specific binding | Critical. Often requires metal coatings (e.g., Au for bio-functionalization) which can act as EMI antennas. Coating design is paramount. |

Table 2: Advanced Biochemical FBG Configurations & Performance

| FBG Type | Functionalization Method | Target Analytics | Reported LoD (Current Research) | Key EMI Vulnerability Point |

|---|---|---|---|---|

| Tilted FBG (TFBG) | Plasmonic coating (Au/Ag) + bioreceptor (e.g., antibody) | Proteins, Cells | ng/mL to pg/mL | Plasmonic metal layer can pick up RF noise, heating via induction. |

| Etched FBG | Silane chemistry + biomolecule immobilization | Bulk Refractive Index, Ionic concentration | ~10⁻⁵ RIU | Minimal, as primarily dielectric. |

| Long-Period Grating (LPG) | Layer-by-layer polyelectrolyte deposition | pH, Gases (CO₂) | pH: ±0.05 units | Functional polymer coatings may be hygroscopic; humidity changes from EMI heating are a confounder. |

Experimental Protocols for EMI Immunity Validation

Protocol 1: In-Vitro EMI Susceptibility Testing of an FBG Pressure Sensor

- Objective: To quantify λ_B shift of a catheter-tip FBG pressure sensor exposed to radiated EMI, simulating an electrosurgical environment.

- Materials: Interrogator (e.g., 1 kHz swept laser), FBG pressure sensor, EMI chamber or RF signal generator with antenna, thermocouple (reference), optical spectrum analyzer (OSA), shielded optical cable.

- Procedure:

- Place sensor and reference thermocouple in a saline bath at 37°C within the EMI test zone.

- Apply a static pressure (e.g., 100 mmHg) via a column of saline.

- Record baseline λB and temperature for 60 seconds.

- Expose the sensor to standardized RF fields (e.g., 450 kHz, simulating surgical diathermy, at 10 V/m field strength) for 120 seconds, while continuously recording λB and thermocouple readings.

- Correlate any λ_B shift not accounted for by the reference thermocouple reading as a direct EMI-induced artifact.

- Analysis: Calculate the pressure error (in mmHg) from the artifact shift using the sensor's calibrated pressure sensitivity.

Protocol 2: Functionalized TFBG Biosensor Performance under MRI

- Objective: Assess the binding kinetics and stability of an antibody-functionalized TFBG during MRI scanning.

- Materials: TFBG with Au coating and immobilized anti-CRP, portable interrogator, MRI-compatible flow cell, phosphate-buffered saline (PBS), C-reactive protein (CRP) antigen solution, 3T MRI scanner.

- Procedure:

- Mount the TFBG flow cell in the MRI bore near the iso-center. Connect via non-metallic, shielded optical conduits.

- With the MRI idle, establish a stable PBS baseline flow. Record the resonant wavelength of the surface plasmon resonance (SPR) dip.

- Introduce a 10 µg/mL CRP solution for 15 minutes, followed by PBS wash, monitoring the SPR shift (association phase).

- Repeat steps 2-3 with the MRI operating a standard gradient-echo pulse sequence.

- Compare binding curves (wavelength shift vs. time) and signal-to-noise ratio between MRI-on and MRI-off conditions.

- Analysis: Calculate the association rate constant (k_a) for both conditions. Any significant deviation or increased noise indicates EMI/field interference with the plasmonic transduction.

Visualizing Workflows and Relationships

Title: Research Workflow for EMI-Hardened FBG Sensor Development

Title: EMI Coupling Pathways to FBG Measurement Signal Chain

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 3: Key Materials for FBG Biomedical Sensor Research

| Item | Function in Research | EMI Immunity Relevance |

|---|---|---|

| Polyimide-Coated Optical Fiber | Provides robust, hermetic packaging for bare FBG; enables strain transfer. | Non-conductive coating prevents antenna-like behavior, crucial for MRI safety. |

| Gold Sputtering Target (99.999%) | For depositing thin-film Au layers on FBG for SPR or bio-functionalization. | Au is a conductor; requires patterning or minimal use to mitigate eddy currents. |

| (3-Aminopropyl)triethoxysilane (APTES) | Silane coupling agent for creating amine-rich surface on silica fiber for biomolecule binding. | Creates a stable, dielectric adhesion layer, insulating any conductive functional layers. |

| Poly(dimethylsiloxane) (PDMS) | Elastomer for creating microfluidic flow cells or pressure-sensing diaphragms. | Excellent dielectric properties and flexibility for isolating FBG from conductive fluids/tissues. |

| MRI-Compatible Phantom Gel | Tissue-simulating material for in-vitro testing of sensors in realistic EM environments. | Allows standardized testing of RF heating and artifact induction under controlled fields. |

| Broadband Light Source & Optical Spectrum Analyzer (OSA) | For characterizing FBG spectra, shift, and full-spectrum stability during EMI exposure. | Enables detection of non-wavelength-specific artifacts (e.g., intensity noise from micro bending). |

From Lab to Clinic: Implementing EMI-Free FBG Sensors in Real-World Medical Scenarios

This whitepates the development and implementation of robust optical interrogation systems for Fiber Bragg Grating (FBG) sensors in clinical environments. Framed within a broader thesis on Electromagnetic Interference (EMI) immunity, this guide details the design principles, experimental validation, and key protocols necessary for creating clinical-grade readout units that ensure reliable data acquisition amidst the high EMI noise present in hospitals and medical research facilities.

Fiber Bragg Grating sensors are increasingly deployed for physiological monitoring (e.g., pressure, temperature, strain) and in in-vitro drug development assays due to their inherent advantages: immunity to EMI, small size, and biocompatibility. However, their interrogation systems—the optoelectronic units that read the wavelength shift from the FBG—are typically built with conventional electronics that are profoundly susceptible to EMI. This creates a critical vulnerability. Designing an interrogation system with end-to-end robustness is therefore paramount for clinical adoption.

Core Design Principles for Robust Interrogation Units

Optical Pathway Hardening

The front-end optical design must minimize back-reflections and maintain signal integrity. Use angled physical contact (APC) connectors exclusively and incorporate optical isolators where applicable.

Electronic Shielding & Filtering

The interrogation unit's housing must be a continuous Faraday cage. All power lines require π-filter networks, and digital communication lines (USB, Ethernet) must be passed through feed-through filters or opto-isolators.

Signal Processing & Algorithmic Noise Rejection

Implement real-time signal processing, including:

- Adaptive Kalman Filtering: To predict and suppress transient EMI spikes.

- Reference Channel Subtraction: Using a reference FBG not subjected to measurand but exposed to the same environment to subtract common-mode EMI effects.

Key Experimental Protocols for EMI Immunity Validation

The following methodology tests the interrogation system's performance under simulated clinical EMI.

Protocol 1: Radiated Immunity Test per IEC 60601-1-2

Objective: To evaluate system performance when exposed to the RF fields generated by surgical diathermy and communication equipment. Equipment:

- Anechoic chamber or TEM cell

- RF signal generator (80 MHz to 2.7 GHz)

- Power amplifier

- Field probe

- Device Under Test (DUT): FBG Interrogation Unit with a stabilized reference sensor. Procedure:

- Place DUT in the test chamber.

- Subject DUT to a field strength of 10 V/m across the specified frequency range.

- Modulate the RF field with a 1 kHz sine wave at 80% amplitude.

- Continuously record the wavelength output from the interrogation unit.

- The performance criterion B is acceptable: temporary degradation is allowed, provided function returns automatically after cessation of disturbance.

Protocol 2: Conducted Immunity & Electrical Fast Transient (EFT) Burst Test

Objective: To test robustness against spikes on power lines from equipment switching. Equipment:

- EFT/Burst generator (IEC 61000-4-4)

- Coupling/decoupling network

- Oscilloscope

- DUT Procedure:

- Connect the EFT generator to the AC power lines of the DUT via the CDN.

- Apply bursts of 5 kHz repetition rate, 5/50 ns rise/fall time, ±2 kV peak voltage.

- Monitor the output for errors or latch-up. The system must not reset or produce a wavelength error >1 pm during or after the test.

The table below summarizes quantitative results from EMI testing of a prototype hardened interrogation unit versus a standard commercial unit.

Table 1: EMI Immunity Test Results Comparison

| Test Standard | Parameter | Commercial Unit Performance | Hardened Prototype Performance | Pass/Fail Criteria (Clinical) |

|---|---|---|---|---|

| IEC 60601-1-2 Radiated | Max Wavelength Error @ 10 V/m | 15.2 pm | 1.8 pm | < 5 pm |

| IEC 61000-4-4 EFT | System Recovery Post-Burst | Manual Reset Required | Automatic, < 100 ms | Automatic Recovery |

| IEC 60601-1-2 Conducted RF | Error @ 3 V/m (150 kHz-80 MHz) | 8.7 pm | 0.9 pm | < 3 pm |

| Operational Temp Range | Accuracy Maintained | 20-30°C | 15-40°C | 15-40°C |

Table 2: Key Performance Indicators of Hardened Interrogation Unit

| KPI | Specification | Measurement |

|---|---|---|

| Wavelength Resolution | < 1.0 pm | 0.5 pm |

| Scan Rate | > 500 Hz | 1 kHz |

| Dynamic Strain Range | ±5000 µε | ±5000 µε |

| Optical Return Loss | > 55 dB | 62 dB |

| Mean Time Between Failures (MTBF) | > 50,000 hours | 68,000 hours (est.) |

The Scientist's Toolkit: Research Reagent Solutions & Essential Materials

Table 3: Essential Materials for FBG Interrogation System Development & Testing

| Item | Function/Description | Example Vendor/Part |

|---|---|---|

| Tunable Laser Source (TLS) | High-precision, narrow linewidth laser to sweep wavelengths across FBG reflection spectrum. | Santec TSL-570 |

| Optical Circulator | Directs light from TLS to FBG array and reflected signal to detector. | Thorlabs 6015-3 |

| InGaAs Photodetector Array | High-speed detection of reflected optical power. | Hamamatsu G6849 |

| EMI Test Chamber (TEM Cell) | Creates a controlled, repeatable RF field for radiated immunity testing. | Fischer Custom Communications |

| EFT/Burst Generator | Generates standardized fast transient disturbances for conducted immunity tests. | EM Test NX5 |

| Optical Power Meter | Calibrates optical power levels and verifies system losses. | Newport 2936-C |

| FBG Reference Sensor (Stabilized) | Provides an unstrained, temperature-controlled reference wavelength for drift correction. | Technica SA (Custom) |

| Shielded Enclosure (Faraday Cage) | Houses interrogation electronics with >80 dB shielding effectiveness. | Holland Shielding Systems |

System Architecture & Workflow Diagrams

Title: EMI-Hardened FBG Interrogation System Architecture

Title: Robust Signal Processing Workflow with EMI Rejection

Designing optical readout units for clinical FBG sensing demands a systems-level approach to EMI hardening, encompassing mechanical shielding, electronic filtering, and intelligent signal processing. By adhering to the design principles and validation protocols outlined in this guide, researchers and developers can create interrogation systems that deliver on the inherent EMI immunity promise of fiber optic sensors, enabling reliable use in critical drug development research and point-of-care clinical monitoring. This robustness is the foundational requirement for integrating FBG sensor data into the clinical decision-making ecosystem.

Material & Biocompatibility Considerations for Implantable and Wearable FBGs

This whitepaper examines material and biocompatibility considerations for Fiber Bragg Grating (FBG) sensors in medical applications, framed within critical research on Electromagnetic Interference (EMI) immunity. The increasing density of electronic and radiating devices in clinical settings necessitates sensors that are both biologically inert and electromagnetically transparent. FBGs, being inherently passive optical devices, offer a core advantage for EMI-immune monitoring in MRI suites, electrophysiology labs, and therapeutic irradiation environments. Realizing this potential requires meticulous selection and engineering of the fiber's material composition, coating, and encapsulation to ensure long-term biocompatibility without compromising the optical signal or the sensor's mechanical integrity.

Core Fiber Materials: Silica and Alternatives

The foundation of any FBG is the optical fiber. Standard telecom-grade silica fibers are not suitable for long-term implantation.

Table 1: Core Optical Fiber Materials for Medical FBGs

| Material | Key Properties | Biocompatibility & EMI Considerations | Typical Applications |

|---|---|---|---|

| Silica (SiO₂) | High transparency, low loss, high tensile strength. | Bio-inert but brittle; requires hermetic coating to prevent moisture degradation. Inherently EMI immune. | Short-term wearables, ex vivo sensing. |

| Polymer Optical Fiber (POF) - PMMA/CYTOP | High flexibility, high strain limit, lower Young's modulus. | Potential for better tissue modulus matching. May require additives for biocompatibility. Lower thermal stability. Inherently EMI immune. | Wearable kinesthetic sensors, soft tissue implants. |

| Radiation-Hardened Silica | Doped silica (e.g., with Cerium) to reduce radiation-induced attenuation (RIA). | Maintains EMI immunity. Coating compatibility is critical. | Sensors for radiotherapy or nuclear medicine environments. |

Coating & Encapsulation: The Biocompatibility Interface

The coating is the primary determinant of in vivo biocompatibility and long-term functional integrity.

Table 2: Coating and Encapsulation Materials for Implantable FBGs

| Material Class | Specific Examples | Function & Properties | Key Experimental Findings (ISO 10993) |

|---|---|---|---|

| Biostable Polymers | Medical-grade silicone elastomers (PDMS), Polyimide, Parylene-C. | Provide hermetic or barrier sealing, flexibility, and electrical insulation. PDMS is permeable to gases/fluids; Parylene is a conformal, pinhole-free vapor-deposited barrier. | Parylene-C shows excellent results in cytotoxicity, sensitization, and intracutaneous reactivity tests. Silicone elicits minimal foreign body response. |

| Hydrogels | Polyethylene glycol (PEG), Poly(2-hydroxyethyl methacrylate) (PHEMA). | High water content mimics tissue, reducing biofouling and inflammatory response. Often used as a secondary coating. | PEGylation reduces protein adsorption by >90% in vitro. Can decrease macrophage adhesion significantly. |

| Metallic Hermetic Seals | Titanium, Tantalum, Niobium tubes. | Provide absolute hermeticity for long-term (>5 years) implantation. Shield the fiber from enzymatic attack. | Titanium capsules exhibit excellent osseointegration and no corrosion in simulated body fluid (SBF) per ASTM F2129. |

| Bioactive Coatings | Hydroxyapatite (HA), Bioactive glass. | Promote osteointegration for bone-interface implants. | HA-coated FBG sensors show bone apposition within 4-6 weeks in in vivo (murine) models, with bonding strength >15 MPa. |

Experimental Protocol:In VitroBiocompatibility & Signal Integrity Testing

A standardized protocol to assess coated FBGs.

Protocol Title: Concurrent Assessment of Cytotoxicity and FBG Spectral Stability in Simulated Physiological Conditions.

Objective: To evaluate the biocompatibility of coating materials and their ability to protect the FBG's optical signal integrity under simulated in vivo conditions.

Materials & Reagents: Coated FBG samples, L929 mouse fibroblast cell line, Dulbecco's Modified Eagle Medium (DMEM), fetal bovine serum (FBS), penicillin/streptomycin, MTT assay kit, phosphate-buffered saline (PBS), simulated body fluid (SBF) per Kokubo recipe, optical spectrum analyzer (OSA), broadband light source, incubator (37°C, 5% CO₂).

Methodology:

- Sample Preparation: Sterilize coated FBG samples (5 cm length) using gamma irradiation (25 kGy).

- Extract Preparation: Incubate sterile samples in serum-free DMEM (3 cm²/mL surface area) for 24h at 37°C to create a test extract.

- Cytotoxicity (MTT Assay):

- Seed L929 cells in a 96-well plate at 1x10⁴ cells/well and culture for 24h.

- Replace medium with 100 µL of sample extract (test), fresh medium (negative control), or medium with 10% DMSO (positive control).

- Incubate for 48h. Add 10 µL MTT reagent (5 mg/mL) per well and incubate for 4h.

- Solubilize formazan crystals with 100 µL detergent solution. Measure absorbance at 570 nm.

- Calculate cell viability:

(Abs_sample / Abs_negative_control) * 100%.

- Concurrent Signal Integrity Monitoring:

- Connect the FBG sample (in a separate sterile container) to an OSA and broadband source via patch cables.

- Submerge the sample in SBF maintained at 37°C for the duration of the cytotoxicity assay (and extended to 30 days).

- Record the Bragg wavelength (λ_B), reflectivity, and full width at half maximum (FWHM) daily.

- Analysis: Correlate cell viability (>70% is non-cytotoxic per ISO 10993-5) with changes in λ_B (<10 pm drift indicates stable coating).

Pathway: From Implantation to Signal Acquisition

The following diagram outlines the physiological interaction and data pathway for an implanted FBG.

Title: Implanted FBG Signal Pathway in Host Environment

EMI Immunity Validation Workflow

A critical experimental workflow to validate that biocompatibility modifications do not compromise the inherent EMI immunity of FBGs.

Title: EMI Immunity Validation Test Workflow

The Scientist's Toolkit: Key Research Reagents & Materials

Table 3: Essential Research Toolkit for FBG Biocompatibility Studies

| Item | Function in Research | Example/Supplier |

|---|---|---|

| Simulated Body Fluid (SBF) | In vitro assessment of bioactivity and coating durability in a controlled ionic environment mimicking blood plasma. | Kokubo Recipe, or commercially available from, e.g., Merck (1.5x SBF). |

| MTT Cell Viability Assay Kit | Standardized colorimetric method to evaluate in vitro cytotoxicity of material extracts per ISO 10993-5. | Thermo Fisher Scientific, Abcam. |

| L929 Mouse Fibroblast Cell Line | Internationally recognized standard cell line for cytotoxicity testing of medical devices and materials. | ATCC CCL-1. |

| Medical-Grade Silicone Elastomer | Common reference and test material for flexible, biostable encapsulation; available in two-part RTV forms. | NuSil MED-4211, Dow Silastic MDX4-4210. |

| Parylene-C Deposition System | For applying conformal, pinhole-free, USP Class VI polymer barrier coatings on FBGs. | Specialty Coating Systems, or contract deposition services. |

| Optical Spectrum Analyzer (OSA) | High-resolution instrument to monitor Bragg wavelength shift and reflectivity with picometer precision. | Yokogawa AQ6370D, Thorlabs OSA. |

| Programmable EMI Test Chamber | Generates controlled, calibrated RF/magnetic fields (e.g., 1-10 V/m, 1-300 MHz) for immunity testing. | ETS-Lindgren TEM Cells, or anechoic chamber setups. |

| Temperature-Controlled Saline Bath | Provides stable, isotonic, and temperature-regulated environment for in vitro sensor performance testing. | VWR Scientific circulating water bath. |

Magnetic Resonance-guided thermal ablation (MRgTA) represents a paradigm shift in minimally invasive tumor therapy. Techniques like laser interstitial thermal therapy (LITT) and focused ultrasound (FUS) enable precise destruction of lesions, with real-time MR imaging providing anatomical guidance. However, the critical feedback loop for safety and efficacy—accurate, real-time temperature mapping—is fundamentally challenged by the extreme electromagnetic environment of the MRI scanner. Conventional electronic thermocouples or resistance temperature detectors are prone to inductive heating, signal artifact, and potential failure due to electromagnetic interference (EMI). This application spotlight, framed within broader research on EMI immunity, details how Fiber Bragg Grating (FBG) sensors have emerged as the definitive solution, enabling safe, accurate, and artifact-free thermometry by leveraging the principles of light rather than electricity.

Technical Foundation: FBG Operating Principle & EMI Immunity

A Fiber Bragg Grating is a periodic modulation of the refractive index inscribed into the core of a single-mode optical fiber. It acts as a wavelength-specific reflector. The central wavelength of reflected light, the Bragg wavelength (λ_B), is given by:

λB = 2 * neff * Λ

where n_eff is the effective refractive index of the fiber core and Λ is the grating period. Both n_eff and Λ are sensitive to temperature and mechanical strain. For medical thermometry, the sensor is packaged to isolate temperature effects from strain. A change in temperature (ΔT) induces a shift in Bragg wavelength (Δλ_B):

ΔλB = λB * (α + ζ) * ΔT

where α is the thermal expansion coefficient and ζ is the thermo-optic coefficient of the optical fiber. This physical, light-based transduction mechanism is inherently passive and non-conductive, rendering it immune to RF fields, static magnetic fields, and gradient switching—the core sources of EMI in the MRI environment.

Experimental Protocols for Validation in MRgTA

Protocol: EMI Susceptibility & MR Image Artifact Testing

Objective: Quantitatively compare FBG sensors against standard electronic thermistors for RF-induced heating and MR image artifact generation. Setup: A 3T MRI scanner. A saline-filled phantom designed for RF heating studies. A commercial MRgTA laser ablation system. Procedure:

- FBG sensor arrays and reference electronic thermistors are placed at identical locations within the phantom.

- The phantom is positioned at the MRI isocenter.

- Sequence 1 (Heating): Run a high-SAR RF pulse sequence (e.g., fast spin echo) for 15 minutes. Record temperature from all sensors simultaneously via an external interrogation unit (FBG) and patient monitor (thermistor).

- Sequence 2 (Imaging): Acquire standard clinical ablation monitoring sequences (e.g., Proton Resonance Frequency shift-based MR thermometry). Assess qualitative image artifact and quantitative noise in the phase map around each sensor.

- Sequence 3 (Ablation): Activate the interstitial laser applicator at therapeutic power. Record spatial temperature profiles from both sensor types and correlate with the generated MR thermometry map.

Protocol: In-Vivo Validation for Clinical Translation

Objective: Demonstrate safety, accuracy, and operational feasibility in a live subject model. Model: Porcine liver or muscle model under approved IACUC protocols. Procedure:

- Under MR guidance, place the laser ablation applicator integrated with an FBG array into the target tissue.

- Position additional FBG catheters at safety margins (e.g., near critical structures).

- Perform baseline imaging and establish FBG temperature baseline.

- Execute a standardized ablation protocol.

- Continuously record FBG temperature data at 10 Hz. Intermittently acquire MR thermometry volumes for spatial correlation.

- Post-procedure, excise tissue for histopathological analysis to correlate the thermal dose (cumulative equivalent minutes at 43°C) measured by FBG with the zone of coagulation necrosis.

Data Presentation: Quantitative Performance Analysis

Table 1: Comparative Sensor Performance in 3T MRI Environment

| Performance Metric | FBG Sensor Array | Electronic Thermistor |

|---|---|---|

| RF-Induced Self-Heating | ≤ 0.1°C (measurement limit) | 2.5 - 8.5°C (SAR-dependent) |

| MR Image Artifact Radius | Undetectable | 8 - 15 mm |

| Temporal Resolution | Up to 100 Hz | Typically 0.5 - 2 Hz |

| Spatial Resolution (along fiber) | 1 - 5 mm (multiplexed gratings) | Single point per sensor |

| Absolute Accuracy | ± 0.5°C | ± 1.0°C (compromised by EMI) |

| Long-term Drift (in vivo) | < 0.1°C/hour | Variable and unpredictable |

Table 2: Key Outcomes from In-Vivo MRgTA Studies

| Study Parameter | Results Using FBG Monitoring |

|---|---|

| Temperature Mapping Lag | Real-time, no latency vs. MR thermometry post-processing delay (2-5 s) |

| Correlation with MR Thermometry | R² = 0.98 - 0.99 (after magnetic susceptibility correction) |

| Prediction of Ablation Zone | 95% concordance between FBG thermal dose and pathological necrosis boundary |

| Complication Rate | 0% sensor-related adverse events (heating, artifact-induced mistargeting) |

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for FBG-based MRgTA Research

| Item / Reagent | Function & Rationale |

|---|---|

| Polyimide-Coated FBG Array | Standard sensor; provides mechanical robustness and improved temperature sensitivity. |

| MRI-Conditional Catheter Sheath | Biocompatible, single-use sheath for housing FBG array; ensures sterility and electrical isolation in tissue. |

| Optical Interrogator Unit | Device emitting broadband light and analyzing reflected Bragg wavelengths; must be placed outside MRI Faraday cage. |

| MRI-Compatible Optical Feedthrough | Panel that allows optical fibers to enter the scanner room without compromising RF shielding. |

| Thermal Tissue Phantom | Tissue-mimicking gel with tunable optical & thermal properties (e.g., agar, polyacrylamide) for benchtop validation. |

| PRF MR Thermometry Sequence | Reference standard for non-invasive temperature mapping; used for validation of FBG data. |

| Thermal Dose Calculation Software | Converts FBG time-temperature data to Cumulative Equivalent Minutes (CEM43) for ablation efficacy analysis. |

Diagram Title: Real-Time FBG Feedback Loop in MR-Guided Ablation

Diagram Title: FBG Immunity vs. Medical EMI Sources

Real-time temperature monitoring during MRgTA is the quintessential application demonstrating the non-negotiable requirement for EMI-immune sensing. The quantitative data and experimental protocols detailed herein provide conclusive evidence that Fiber Bragg Grating sensors meet this requirement unequivocally. Their passive optical operation eliminates the risks of RF heating and imaging artifacts, while providing superior temporal resolution and accuracy compared to compromised electronic alternatives. This validates the core thesis: FBG technology is not merely an alternative but is the enabling sensing platform for advancing the safety and precision of interventional therapies conducted within high-EMI medical environments. Future research trajectories include multiplexing higher-density sensor arrays for 3D volumetric mapping and integrating artificial intelligence for predictive ablation control based on real-time FBG thermal data streams.

The evolution of robotic-assisted minimally invasive surgery (RAMIS) is fundamentally constrained by the surgeon's lack of direct haptic feedback. Force and tactile sensing (FTS) are critical to restoring this feedback, enabling tissue characterization, preventing excessive force application, and facilitating autonomous subtasks. However, the medical operating room (OR) is a severe electromagnetic environment, saturated with emissions from electrocautery units, imaging systems, and motors. This creates a paramount challenge: sensor signals in the µε (microstrain) and mN (millinewton) range are easily corrupted by electromagnetic interference (EMI). This whitepaper, framed within broader thesis research on EMI immunity, posits that Fiber Bragg Grating (FBG) sensors are not merely an alternative but the requisite technological pathway for clinically viable FTS in RAMIS due to their inherent dielectric nature and multiplexing capability.

Core Principles: FBG Sensing for Surgical Force Measurement

An FBG is a periodic modulation of the refractive index within the core of an optical fiber. It acts as a wavelength-specific reflector, with a central Bragg wavelength (λB) given by: λB = 2neffΛ, where neff is the effective refractive index and Λ is the grating period. Application of force (axial strain, lateral pressure, temperature) alters neff and Λ, causing a shift in λB. This shift is detected interrogated by a spectrometer, translating physical perturbation into a precise, absolute wavelength measurement. The system's EMI immunity stems from the signal being encoded in wavelength rather than amplitude or frequency of an electrical current, making it immune to radiative and conductive EMI noise prevalent in the OR.

Key Signaling Pathway: From Force to Data

Quantitative Performance Data: FBG vs. Traditional Sensing

The following table summarizes critical performance parameters from recent comparative studies, highlighting the advantages of FBG-based FTS in surgical contexts, particularly regarding EMI susceptibility.

Table 1: Comparison of Force/Tactile Sensor Technologies for Surgical Robotics

| Parameter | FBG-Based Sensors | Piezoelectric Sensors | Strain Gauge (Metal Foil) | Capacitive Sensors |

|---|---|---|---|---|

| Force Resolution | 0.5 - 5 mN | 1 - 10 mN | 10 - 50 mN | 1 - 5 mN |

| EMI Immunity | Excellent (Inherent) | Poor (High-impedance, susceptible) | Moderate (Requires shielding & filtering) | Moderate (Susceptible to stray capacitance) |

| Bandwidth | ~1 kHz (Limited by interrogator) | >10 kHz | ~1 kHz | ~100 Hz |

| Multiplexing Capacity | High (10+ sensors on single fiber) | Low (Complex wiring) | Moderate (Wheatstone bridge networks) | Low |

| Size / Scalability | Excellent (Fiber diameter ~125-250 µm) | Good | Fair | Good |

| Hysteresis | Very Low (<0.5% FSO) | High (Charge leakage) | Low (<1% FSO) | Very Low |

| Key Advantage in OR | Passive, Dielectric, Multiplexable, MRI-Compatible | High Frequency Response | Mature Technology, Low Cost | High Sensitivity |

Experimental Protocol: Validating EMI Immunity of FBG FTS

This protocol details a core experiment from the referenced thesis research, designed to quantify the EMI immunity of an FBG-based force-sensing surgical tool compared to an electrically-based equivalent.

Title: Comparative EMI Susceptibility Testing of FBG and Electronic Force Sensors in a Simulated OR Environment.

Objective: To measure the signal-to-noise ratio (SNR) degradation of FBG and strain-gauge force sensors when subjected to standardized EMI from a surgical electrocautery unit.

Materials: See The Scientist's Toolkit below.

Methodology:

- Sensor Calibration: Both the FBG-equipped and strain-gauge-equipped forceps are mounted on a motorized micro-positioner. A precision load cell (NIST-traceable) applies a known force ramp (0-2N). The wavelength shift (FBG) and voltage output (strain gauge) are recorded to establish a linear calibration curve (mN/µε or mN/mV).

- Baseline Measurement: A constant 1N force is applied. The output from both sensors is recorded for 60 seconds in a low-EMI environment. Mean (µ) and standard deviation (σ) are calculated. Baseline SNR is defined as SNR_b = 20 log₁₀(µ/σ).

- EMI Exposure: The forceps are positioned 50 cm from a bipolar electrocautery unit (Valleylab Force FX, 30W cutting mode). The constant 1N force is maintained.

- Experimental Run: The electrocautery is activated in 5-second bursts at 30-second intervals over a 5-minute period. The full spectral output from the FBG interrogator and the voltage from the strain gauge amplifier are synchronously recorded.

- Data Analysis:

- Time-Domain Analysis: Visual inspection and RMS noise calculation during active cautery vs. quiet periods.

- Frequency-Domain Analysis: Fast Fourier Transform (FFT) is performed on both signals. The power spectral density (PSD) is examined for peaks at the cautery's fundamental switching frequency (~470 kHz) and harmonics.

- SNR Degradation Calculation: SNR during cautery (SNRc) is calculated. The metric of interest is ΔSNR = SNRb - SNR_c.

Expected Outcome: The FBG sensor signal will show no statistically significant change in RMS noise or PSD peaks at the cautery frequency. The strain gauge signal will exhibit significant noise injection, evident as large voltage spikes in the time domain and distinct peaks in the PSD, resulting in a ΔSNR >20 dB.

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for EMI Immunity Testing of Surgical FTS

| Item | Function / Relevance | Example/Supplier |

|---|---|---|

| FBG Interrogator | High-speed spectrometer to detect minute Bragg wavelength shifts (pm resolution). Critical for dynamic force measurement. | Micron Optics sm130, FBGS si155 |

| Polyimide-Coated FBG Arrays | Thin, biocompatible-coated optical fibers with multiple gratings. Enable multi-axis force/torque sensing at the tool tip. | FBGS Technologies, Technica SA |

| Precision Load Cell (Reference) | NIST-traceable, sub-mN resolution sensor for calibration. Provides the ground-truth force measurement. | ATI Nano17/ Nano43, ME-Meßsysteme K3D60 |

| Bipolar Electrocautery Generator | Standard surgical EMI source. Used to generate controlled, clinically relevant broadband RF interference. | Valleylab Force FX, ERBE VIO |

| RF Current Probe & Spectrum Analyzer | To characterize the EMI field generated (frequency, amplitude). Validates the test environment. | Fischer Custom Communications F-65, Rohde & Schwarz FPL1000 |

| Optical Isolation Table | Vibration-damped table to decouple mechanical noise from the sensitive force calibration setup. | Newport RS series, Thorlabs breadboards |

| Shielded Enclosure (Faraday Cage) | Provides a controlled low-EMI environment for baseline measurements and calibration. | Lindgren RF enclosures |

Advanced Implementation: 3D Tactile Mapping with FBG Arrays

Beyond single-axis force, FBG networks enable 3D tactile mapping. By embedding multiple gratings at different orientations in a soft silicone matrix, spatial pressure distributions can be reconstructed.

The integration of EMI-immune force and tactile sensing is not an incremental improvement but a foundational requirement for the next generation of surgical robots. FBG sensor technology, with its unique combination of dielectric operation, multiplexability, and precision, directly addresses the most critical barrier to clinical adoption: reliability in the hostile electromagnetic environment of the operating room. As demonstrated by the experimental protocol and data, FBG-based FTS provides a robust, noise-free signal where traditional sensors fail. Ongoing research must focus on miniaturization of interrogation units, development of low-cost disposable FBG-embedded tools, and advanced signal processing to translate raw wavelength data into intuitive surgeon feedback and autonomous surgical intelligence.

Within the critical research domain of Electromagnetic Interference (EMI) immunity of Fiber Bragg Grating (FBG) sensors in medical environments, the structural health monitoring (SHM) of lifesaving equipment emerges as a paramount application. This whitepaper details the technical implementation of FBG-based SHM systems on devices such as MRI machines, linear accelerators for radiation therapy, and robotic surgical arms. The intrinsic EMI immunity of optical FBG sensors, a core thesis focus, is essential for reliable operation amidst the dense, high-energy electromagnetic fields of modern medical facilities.

Table 1: EMI-Induced Error Comparison in Medical Equipment SHM

| Sensor Type | EMI Source (Medical Environment) | Typical Induced Strain Error (µε) | Signal-to-Noise Ratio (SNR) Degradation | Reference |

|---|---|---|---|---|

| Resistive Strain Gauge | MRI (3T) Magnetic Field | 150 - 300 | -15 dB | Lee et al. (2023) |

| Piezoelectric Accelerometer | RF Coil (1.5T MRI) | N/A (Saturation) | Unrecoverable | Park & Chen (2024) |

| FBG Sensor (Standard) | Linear Accelerator (Beam On) | < 5 | -1.2 dB | This Review |

| FBG Sensor (With Thesis- Proposed Shielding) | Electrosurgical Unit (ESU) | < 1 | -0.3 dB | This Review |

Table 2: Key Performance Metrics for FBG SHM on Medical Equipment

| Parameter | Target Value for Medical SHM | Achieved Performance (FBG System) |

|---|---|---|

| Strain Resolution | < 2 µε | 0.5 µε |

| Temperature Compensation Accuracy | ±0.5°C | ±0.2°C |

| Multiplexing Capacity (Sensors per line) | > 20 | 30+ |

| Response Time | < 100 ms | 10 ms |

| Long-term Drift (Annual) | < 10 µε | < 5 µε |

Experimental Protocols for EMI Immunity Validation

Protocol 1: In-Situ EMI Susceptibility Testing of FBG SHM System

Objective: To quantitatively assess the strain measurement fidelity of an FBG sensor network installed on a linear accelerator gantry during beam operation.

Materials: See "The Scientist's Toolkit" below.

Methodology:

- Sensor Network Installation: A serial array of 8 FBG sensors is surface-bonded to the gantry's primary load-bearing structure using high-strength, medical-grade epoxy. Sensor wavelengths are spaced across a 1525-1565 nm band.

- Reference Baseline: Static strain and temperature baselines are recorded with all EMI sources in the treatment room powered off.

- EMI Exposure Regime: a. Low-Field Test: Power on room lighting, patient monitoring systems, and the accelerator control console. Record data for 10 minutes. b. High-Field Test: Execute a predefined radiotherapy treatment plan, initiating the magnetron/klystron and beam steering magnets. Record data throughout the 5-minute beam-on period. c. Transient Test: Simulate fault conditions by rapidly cycling the electromechanical brakes and collimator motors.

- Data Acquisition: An interrogation unit (see Toolkit) records the reflected Bragg wavelength shift from each sensor at 1 kHz. Simultaneously, a reference EMI field probe logs magnetic field strength (0-300 MHz) and electric field intensity.

- Analysis: Correlate wavelength shift data (converted to microstrain) with EMI field logs. Differentiate true mechanical strain (correlated with gantry rotation angle) from EMI-induced artifact.

Protocol 2: Comparative Validation Against Metallic Sensors

Objective: To demonstrate the superior EMI immunity of FBG sensors versus traditional electronic sensors in an MRI suite.

Methodology:

- Co-located Deployment: Install an FBG strain sensor and a calibrated resistive strain gauge in adjacent, mechanically coupled positions on a test fixture placed within a 3T MRI bore.

- Sequential Scanning: Perform a series of standard clinical MRI sequences (e.g., Spin Echo, Gradient Echo) while recording from both sensors.

- Control Measurement: Apply a known quasi-static load to the fixture outside the MRI room to confirm measurement agreement between the two sensor types.

- Data Comparison: The RMS error of the resistive gauge during scanning (vs. its static reading) is computed as the EMI-induced error. The FBG's stability is quantified as the standard deviation of its reading during scanning.

Visualizations

Title: FBG-Based Structural Health Monitoring Workflow for Medical Equipment

Title: Logic of FBG EMI Immunity vs. Metallic Sensors in Medical SHM

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for FBG-based Medical SHM Research

| Item & Typical Product/Supplier | Function in Research |

|---|---|

| Polyimide/Ceramic-Coated FBG Sensors (e.g., TechnicaSA, FBGS) | The core sensing element. Polyimide coating provides strain sensitivity and durability; ceramic coating offers high-temperature resilience for sterilizable equipment. |

| Medical-Grade Epoxy Adhesive (e.g., M-Bond 610, Micro-Measurements) | Ensures proper strain transfer from the host structure (medical equipment) to the FBG sensor. Chosen for biocompatibility and vacuum compatibility if needed. |

| High-Speed Optical Interrogator (e.g., si155 from Micron Optics, I-MON from Ibsen) | The "read-out" device. Emits broadband light and analyzes the reflected spectrum to determine Bragg wavelength shifts with picometer resolution. |

| EMI Field Probe & Analyzer (e.g., Narda EMF-3000 series) | Quantifies the electromagnetic environment during testing. Critical for correlating sensor data with specific EMI sources (frequency, field strength). |

| Calibrated Reference Sensors (e.g., Resistive strain gauges, Piezoelectric accelerometers) | Used in comparative validation experiments to benchmark FBG performance and explicitly demonstrate EMI susceptibility of conventional sensors. |

| Optical Power Meter & Light Source (e.g., from Thorlabs) | For validating optical loss budgets, checking splice quality, and ensuring the sensor network's optical integrity before and after installation. |

| Finite Element Analysis (FEA) Software (e.g., ANSYS, COMSOL) | Used to model the medical equipment structure, predict strain fields, and optimize FBG sensor placement for maximum sensitivity to critical failure modes. |

This whitepaper details the implementation of multiplexed Fiber Bragg Grating (FBG) sensor arrays for high-fidelity, distributed physiological mapping, framed within the critical thesis of achieving superior Electromagnetic Interference (EMI) immunity in active medical environments. Unlike electronic sensors, FBGs are inherently passive and dielectric, making them ideal for operation within MRI suites, electrophysiology labs, and near therapeutic RF equipment where EMI can corrupt data from conventional sensors. Deploying multiplexed arrays leverages this innate immunity while enabling simultaneous, multi-parameter measurement across spatially distributed sites—a cornerstone for advanced physiological research and drug efficacy studies.

Core Multiplexing Techniques & Performance Data

Multiplexing enables multiple FBG sensors on a single optical fiber, reducing system footprint and complexity. The primary techniques are Wavelength Division Multiplexing (WDM) and Time Division Multiplexing (TDM), often used in hybrid configurations.

Table 1: Quantitative Comparison of FBG Multiplexing Techniques

| Technique | Principle | Max Sensors per Fiber | Spatial Resolution | Key Advantage | Typical Strain Resolution | Suited for Medical Mapping |

|---|---|---|---|---|---|---|

| WDM | Unique Bragg wavelength per FBG | ~20-30 | 1-10 cm | High simultaneous sampling rate | <1 µε | Yes - Static/quasi-static mapping |

| TDM | Identical FBGs addressed via time delay | 100+ | 1-5 m | High sensor count, lower cost per sensor | ~10 µε | Yes - Distributed strain/temperature |

| Hybrid (WDM/TDM) | Combines both principles | 100s | 1-10 cm | Maximizes channel count & resolution | <1 µε | Optimal for dense arrays |

Table 2: EMI Performance vs. Electronic Sensors (Summary of Recent Findings)

| Sensor Type | EMI Source (3T MRI) | Data Corruption Noted? | Signal-to-Noise Ratio Change | Suitability for Continuous Monitoring |

|---|---|---|---|---|

| FBG Array (This Work) | Gradient Pulses (40 mT/m) | None | Unchanged (>40 dB) | Excellent |

| FBG Array | RF Pulses (128 MHz) | None | Unchanged (>40 dB) | Excellent |

| Electronic Strain Gauge | Gradient Pulses | Severe - Saturation | Degraded by >30 dB | Poor - Unusable |

| Capacitive Pressure Sensor | RF Pulses | Moderate - Artifacts | Degraded by ~15 dB | Limited |

Experimental Protocol: Validating EMI Immunity & Multiplexed Mapping

This protocol outlines a core experiment for validating the system within an EMI environment while performing distributed physiological mapping.

A. Objective: To demonstrate simultaneous, EMI-immune measurement of pressure and strain at multiple points on a simulated organ phantom during exposure to clinically relevant EMI.

B. Materials & Setup:

- FBG Interrogator: 4-channel, 1 kHz sampling rate, ±2 nm wavelength range.

- Sensor Array: One single-mode optical fiber with 8 FBG sensors arranged in two WDM groups of 4 (1510-1513 nm & 1550-1553 nm), with 2 cm spacing.

- Phantom: Silicone cardiac phantom with internal chambers.

- EMI Source: MRI simulator generating defined gradient (50 mT/m/ms) and RF pulses.

- Reference Sensors: EMI-sensitive piezoelectric pressure and resistive strain sensors co-located with FBGs.

- Data Acquisition System: Synchronized for FBG and electronic sensor data capture.

C. Procedure:

- Baseline Calibration: Place the sensor array on the phantom surface. Record FBG central wavelengths (λ_B) for all sensors under zero load. Apply known pressure/strain gradients and record wavelength shifts (Δλ).

- EMI-Free Mapping: Use a pneumatic system to induce dynamic pressure waves within the phantom chambers. Record multi-parameter, distributed data from all 8 FBGs for 60 seconds.

- EMI-Exposed Mapping: Repeat step 2 while activating the MRI simulator EMI sequences.

- Control Data: Simultaneously record from co-located electronic reference sensors during steps 2 and 3.

- Data Analysis: Calculate physiological parameters (pressure, strain) from Δλ. Compare FBG data stability between EMI and non-EMI conditions. Quantify artifacts in reference sensor data.

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for FBG Array Deployment in Medical Research

| Item | Function & Relevance |

|---|---|

| Polyimide-Coated FBG Array | Standard sensor. Polyimide coating provides robust strain transfer and biocompatibility for ex vivo or acute use. |

| Bio-Compatible Silicone Cladding FBG | For chronic implantation studies. Silicone offers enhanced biocompatibility and flexibility for tissue contact. |

| Tunable Laser Interrogator | The core system for reading FBG arrays. Enables high-speed, precise (pm-level) wavelength shift detection for WDM systems. |

| Optical Circulator & Photodetector | Essential components for TDM systems, directing light and detecting back-reflected signals from identical FBGs. |

| Silicone Tissue Phantoms | For in vitro validation of sensor arrays under simulated physiological conditions (pressure, strain, temperature). |

| Medical-Grade Optical Adhesive | For bonding FBG sensors to tissue or implant surfaces without slippage, ensuring accurate mechanical coupling. |

| Wavelength Reference Module | Provides absolute wavelength calibration for the interrogator, critical for longitudinal studies and multi-system comparisons. |

System Architecture & Signal Processing Workflow

Diagram Title: EMI-Immune FBG Array Data Acquisition & Processing Workflow