Decoupling Strain and Temperature: Advanced FBG Sensors for Precision Healthcare Monitoring and Diagnostics

This article provides a comprehensive analysis of Fiber Bragg Grating (FBG) sensor technology, focusing on the critical challenge of simultaneous strain and temperature sensitivity in biomedical applications.

Decoupling Strain and Temperature: Advanced FBG Sensors for Precision Healthcare Monitoring and Diagnostics

Abstract

This article provides a comprehensive analysis of Fiber Bragg Grating (FBG) sensor technology, focusing on the critical challenge of simultaneous strain and temperature sensitivity in biomedical applications. Tailored for researchers and drug development professionals, it explores the fundamental principles of FBG operation, details advanced methodologies for decoupling these parameters in vivo, addresses key troubleshooting and optimization strategies for real-world clinical environments, and presents a comparative validation of current sensor architectures. The synthesis offers a roadmap for integrating highly precise, multiplexed FBG systems into next-generation medical devices, wearable monitors, and pharmaceutical research tools.

The Dual-Sensitivity Challenge: Core Principles of FBG Sensors in Biomechanical and Thermal Monitoring

This technical guide details the fundamental physics of Fiber Bragg Gratings (FBGs), focusing on refractive index modulation and the resulting Bragg wavelength condition. Framed within the context of their application in healthcare research, particularly for monitoring strain and temperature in biological systems, this document provides the theoretical groundwork for understanding FBG sensor sensitivity. The core principles are supported by current data, experimental protocols, and essential research toolkits relevant to scientists and drug development professionals.

Core Physics: Refractive Index Modulation

An FBG is a periodic perturbation of the refractive index along a segment of the optical fiber's core. This modulation is typically written by exposing the photosensitive germanium-doped core to an intense interference pattern of ultraviolet (UV) light (often at 244 nm or 248 nm). The exposure creates permanent changes in the core's refractive index through two primary mechanisms: the color center model (defect formation) and the densification model.

The resultant index profile is commonly expressed as:

n(z) = n_eff + Δn_ac * cos((2π/Λ)z + φ(z))

Where:

n_effis the average effective refractive index of the core.Δn_acis the amplitude of the induced index modulation (typically 10^-5 to 10^-3).Λis the grating period.φ(z)is a possible phase term for chirped or phase-shifted gratings.

The Bragg Condition and Reflection

The periodic structure acts as a wavelength-selective mirror. According to coupled-mode theory, the fundamental Bragg wavelength λ_B for peak reflection is given by the first-order condition:

λ_B = 2 * n_eff * Λ

This equation is the cornerstone of FBG operation. Light propagating within the fiber that satisfies this condition is reflected coherently, while other wavelengths are transmitted with minimal loss.

Sensitivity to Strain and Temperature

The sensitivity of an FBG to external perturbations stems from the dependence of n_eff and Λ on strain (ε) and temperature (ΔT). The general shift in Bragg wavelength is:

Δλ_B / λ_B = (1 - p_e) * ε + (α + ζ) * ΔT

Where:

p_eis the photoelastic coefficient (~0.22 for silica).αis the thermal expansion coefficient (~0.55 x 10^-6 /°C for silica).ζis the thermo-optic coefficient (~8.6 x 10^-6 /°C for germanium-doped silica core).

The dual sensitivity necessitates discrimination techniques in sensing applications.

Table 1: Typical FBG Sensitivity Coefficients for Silica Fiber

| Perturbation | Coefficient | Typical Value | Resultant Shift (for λ_B = 1550 nm) |

|---|---|---|---|

| Axial Strain | K_ε |

~1.2 pm/µε | +1.86 nm per 1000 µε |

| Temperature | K_T |

~10.8 pm/°C | +10.8 pm per °C |

| Pressure | K_p |

~ -3.0 pm/MPa | Varies with packaging |

Experimental Protocol: Characterizing FBG Strain Sensitivity

This protocol is essential for calibrating FBGs for biomechanical sensing (e.g., tissue strain, gait analysis).

Objective: To determine the strain sensitivity coefficient K_ε of an FBG sensor.

Materials: FBG sensor, optical interrogator/swept laser system, precision translation stage with micrometer, fiber holders/clamps, temperature-controlled chamber, data acquisition software.

Procedure:

- Mounting: Secure both ends of the fiber containing the FBG onto fixed and movable clamps on the translation stage. Ensure the FBG section is axially aligned and taut without pre-strain.

- Optical Connection: Connect the fiber to the interrogator. Record the initial Bragg wavelength

λ_B0. - Strain Application: Using the micrometer, incrementally displace the movable clamp to induce known axial strain (ε = ΔL / L0). Record displacement and corresponding

λ_B. - Data Collection: Repeat over a strain range relevant to the application (e.g., 0-2000 µε). Maintain constant temperature.

- Analysis: Plot

Δλ_Bversus applied strainε. Perform linear regression. The slope is the experimental strain sensitivityK_ε(pm/µε).

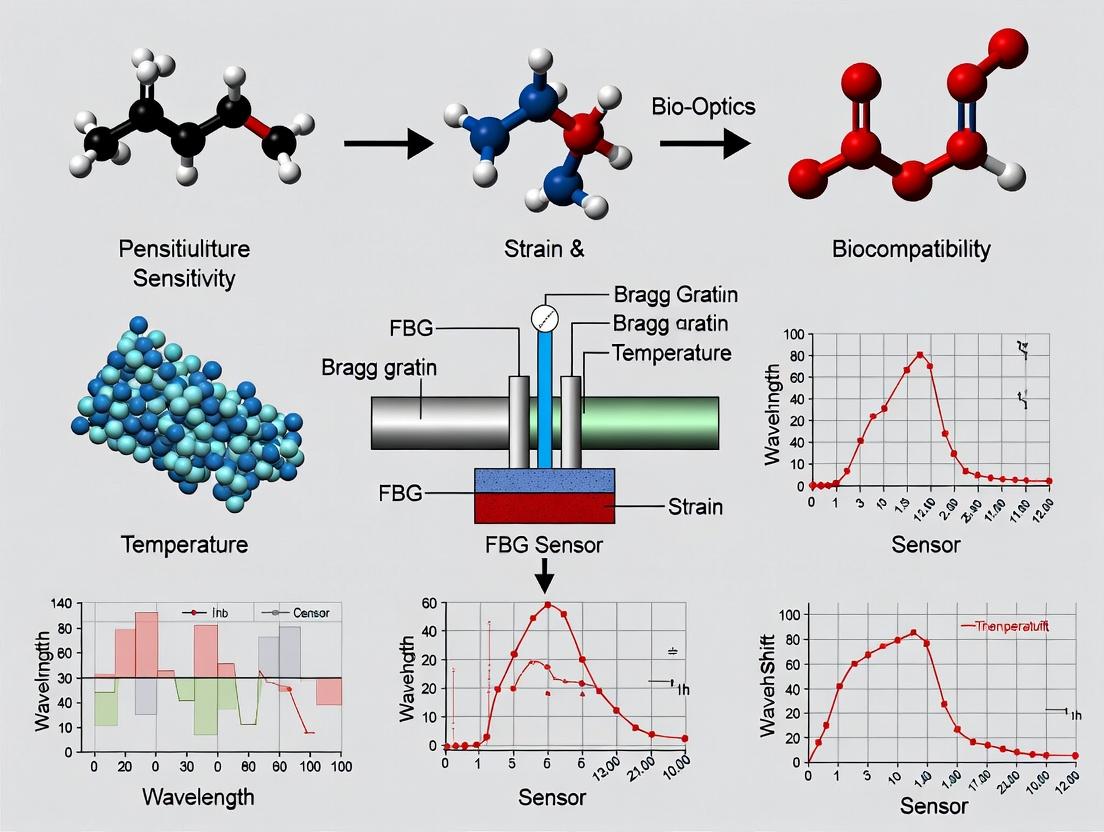

Essential Visualization: FBG Principle & Sensor Response

Title: FBG Fabrication, Bragg Reflection, and Sensor Response Workflow

The Scientist's Toolkit: FBG Sensor Research Essentials

Table 2: Key Research Reagent Solutions & Materials for FBG Healthcare Sensing

| Item | Function/Description | Relevance to Healthcare Research |

|---|---|---|

| Photosensitive Optical Fiber | Typically germanium-doped silica fiber. The substrate into which the Bragg grating is inscribed. | Core sensing element. Biocompatible coatings allow for in-vivo use. |

| UV Laser System (Excimer/ArF) | Provides high-power pulsed UV light (~248 nm) for efficient grating inscription via phase mask technique. | Standard for reliable, high-quality FBG fabrication. |

| Optical Interrogator | A high-resolution spectrometer or swept laser system that measures the spectral shift of the FBG's Bragg wavelength. | Critical for converting optical signal to quantifiable strain/temperature data. |

| Polyimide or Ormocer Coating | Specialized recoating materials applied after grating inscription to protect the fiber and ensure mechanical integrity. | Polyimide offers high strain tolerance. Ormocer provides biocompatibility for implantable sensors. |

| Calibration Apparatus | Precision translation stages, temperature-controlled ovens, and pressure chambers. | Used to characterize and calibrate the FBG's sensitivity coefficients (Kε, KT). |

| Bio-compatible Encapsulation | Materials like medical-grade silicone or PDMS for packaging the FBG into a functional medical sensor. | Isolates the fiber, defines mechanical transfer function, and ensures safety for patient contact or implantation. |

| Data Acquisition & Analysis Software | Custom or commercial software for real-time wavelength tracking, perturbation discrimination, and sensor network multiplexing. | Enables integration of FBG data into clinical or laboratory monitoring systems. |

Experimental Protocol: Temperature Discrimination in a Dual-Parameter FBG Sensor

A common method to separate strain and temperature effects uses two FBGs with different responses.

Objective: To independently measure strain and temperature using a dual-FBG configuration.

Materials: Two FBGs with distinct strain/temperature sensitivities (e.g., one bare, one packaged in a capillary), optical interrogator, calibrated strain rig, thermal chamber.

Procedure:

- Sensor Fabrication: Create Sensor A (bare FBG, sensitive to both ε and ΔT). Create Sensor B (FBG packaged in a material that decouples it from axial strain but not from temperature).

- Co-location: Mount both sensors in the same location on the test structure or tissue phantom.

- Matrix Calibration: Prior to deployment, calibrate each sensor's individual responses to determine the sensitivity matrix:

[Δλ_A; Δλ_B] = [K_εA K_TA; K_εB K_TB] * [ε; ΔT]WhereK_εB ≈ 0. - In-Field Measurement: During the experiment, simultaneously record

Δλ_AandΔλ_B. - Data Analysis: Solve the system of linear equations using the inverse of the calibrated sensitivity matrix to compute the true

εandΔTacting on the sensors.

The operational principle of an FBG is intrinsically linked to the physics of refractive index modulation and the resulting Bragg wavelength condition. Its sensitivity to strain and temperature, while requiring careful management, forms the basis for its powerful application in healthcare research. From monitoring biomechanical forces in rehabilitation to measuring minute temperature changes in tissue during hyperthermia therapy, a rigorous understanding of these core principles enables researchers to design precise, reliable, and multiplexable sensor systems for advanced diagnostic and therapeutic development.

Within the context of healthcare research, Fiber Bragg Grating (FBG) sensors have emerged as a transformative technology for in vivo physiological monitoring, minimally invasive surgery, and biomechanical studies. Their core function relies on the shift in the Bragg wavelength (λ_B) in response to external perturbations. A rigorous understanding of the fundamental sensitivity coefficients—Δλ/Δε for strain and Δλ/ΔT for temperature—is paramount for designing sensors that can accurately discriminate between mechanical and thermal stimuli in complex biological environments. This whitepaper provides an in-depth technical guide to these coefficients, their quantification, and their application in biomedical sensing.

Theoretical Foundation

The Bragg wavelength of an FBG is given by λB = 2neffΛ, where neff is the effective refractive index of the fiber core and Λ is the grating period. Changes in strain (ε) and temperature (T) alter both neff and Λ, causing λ_B to shift.

The total differential defines the fundamental sensitivity coefficients:

Where:

- Δλ_B/Δε is the strain sensitivity coefficient (typically in pm/µε).

- Δλ_B/ΔT is the temperature sensitivity coefficient (typically in pm/°C).

For a standard silica fiber, the strain sensitivity arises primarily from the physical elongation of the grating period and the strain-optic effect. The temperature sensitivity results from the thermal expansion of the fiber material and the thermo-optic effect.

Quantifying the Sensitivity Coefficients: Experimental Protocols

Protocol for Strain Sensitivity Coefficient (Δλ/Δε) Calibration

Objective: To isolate and measure the shift in λ_B per unit applied axial strain.

Materials & Setup:

- FBG sensor affixed to a calibration beam (e.g., aluminum) using high-strength, cyanoacrylate-based adhesive, ensuring axial alignment.

- Precision translation stage or micrometer-driven three-point bending apparatus.

- Optical Interrogator (e.g., swept laser or broadband source with an OSA).

- Resistive strain gauge (reference) bonded adjacent to the FBG.

- Data acquisition system for simultaneous wavelength and strain recording.

Procedure:

- The FBG's initial Bragg wavelength (λ_0) is recorded under zero applied load.

- Known displacements are applied to the calibration beam, inducing controlled, uniform axial strain. The reference strain gauge provides ground-truth ε values.

- At each incremental strain step, the shifted Bragg wavelength (λ_i) is recorded after stabilization.

- Data is collected over a representative strain range (e.g., 0-1000 µε).

- A linear regression of ΔλB (λi - λ_0) versus applied strain (ε) is performed. The slope of the best-fit line is the experimental strain sensitivity coefficient, Δλ/Δε.

Protocol for Temperature Sensitivity Coefficient (Δλ/ΔT) Calibration

Objective: To isolate and measure the shift in λ_B per unit change in temperature, independent of mechanical strain.

Materials & Setup:

- FBG sensor placed loosely (free of strain) inside a precision thermal chamber or oil bath.

- High-accuracy platinum resistance thermometer (PRT) or thermocouple placed adjacent to the FBG.

- Optical Interrogator.

- Temperature controller for the chamber.

Procedure:

- The FBG's initial Bragg wavelength (λ0) is recorded at a baseline temperature (T0, e.g., 20°C).

- The chamber temperature is increased in stable, incremental steps (e.g., 5°C steps from 20°C to 80°C).

- At each temperature plateau, after thermal equilibrium is confirmed, the shifted Bragg wavelength (λi) and the reference temperature (Ti) are recorded.

- A linear regression of ΔλB versus ΔT (Ti - T_0) is performed. The slope of the best-fit line is the experimental temperature sensitivity coefficient, Δλ/ΔT.

Compiled Quantitative Data

The following tables summarize typical sensitivity coefficients for common FBG configurations used in biomedical research.

Table 1: Strain Sensitivity Coefficients (Δλ/Δε)

| FBG Type / Fiber Material | Typical Coefficient (pm/µε) | Key Application Context in Healthcare |

|---|---|---|

| Standard Silica (SMF-28) | ~1.2 | Bone strain monitoring, tendon force measurement. |

| Polymer Optical Fiber (PMMA) | ~-1.4 to -2.0 (negative) | Soft tissue biomechanics, high-compliance sensing. |

| Regenerated Grating (After annealing) | ~1.2 | Implantable sensors requiring high-temperature sterilization. |

Table 2: Temperature Sensitivity Coefficients (Δλ/ΔT)

| FBG Type / Fiber Material | Typical Coefficient (pm/°C) | Key Application Context in Healthcare |

|---|---|---|

| Standard Silica (SMF-28) | ~10 - 11 | Core body temperature monitoring, hyperthermia treatment tracking. |

| Specialty Configurations | ||

| Polymer Optical Fiber (PMMA) | ~-30 to -40 (negative) | Thermal ablation feedback (large sensitivity). |

| Silica FBG with Polymer Coating | ~30 - 50+ | Enhanced sensitivity for subtle physiological temperature changes. |

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for FBG Sensitivity Characterization in Biomedical Research

| Item | Function in Experiment |

|---|---|

| Cyanoacrylate Adhesive (Medical Grade) | For sterile, strong, and rapid bonding of FBG to biological tissues or test fixtures during ex vivo studies. |

| Polyimide Recoating Kit | To apply a thin, biocompatible, and protective polymer coating to bare FBGs post-fabrication, enabling in vivo use. |

| Silicone Encapsulant (Bio-compatible) | To create a protective, flexible encapsulation around the FBG sensor for chronic implantation, isolating it from biological fluids. |

| Calibration Phantom (Agarose or PDMS) | Tissue-mimicking material with tunable mechanical and thermal properties for benchtop simulation of physiological environments. |

| Optical Gel (Index Matching) | To minimize unwanted Fresnel reflections at fiber junctions within the interrogation system, ensuring signal fidelity. |

Diagram: FBG Sensitivity Pathway & Discrimination

Diagram Title: FBG Response Pathway to Strain and Temperature

Diagram: Experimental Protocol for Coefficient Calibration

Diagram Title: Dual-Path Calibration Protocol for FBG Coefficients

In Fiber Bragg Grating (FBG) sensor technology, the intrinsic cross-sensitivity of the Bragg wavelength shift to both strain ((\epsilon)) and temperature (T) presents a fundamental challenge for biomedical applications. This whitepaper details the physical principles of this dual-parameter sensitivity, reviews current decoupling methodologies, and provides experimental protocols for achieving accurate, simultaneous measurement—a critical requirement for reliable data in healthcare research, from implantable device monitoring to advanced drug delivery systems.

An FBG's core operating principle is the reflection of a specific Bragg wavelength ((\lambdaB)) dictated by the effective refractive index ((n{eff})) and the grating period ((\Lambda)). The primary relationship is: (\lambdaB = 2 n{eff} \Lambda)

Both strain and temperature perturbations alter (n{eff}) and (\Lambda), causing an indistinguishable shift in (\lambdaB): (\Delta\lambdaB = \lambdaB (1 - pe)\epsilon + \lambdaB (\alpha + \zeta)\Delta T) where (p_e) is the photo-elastic coefficient, (\alpha) is the thermal expansion coefficient, and (\zeta) is the thermo-optic coefficient.

This dual dependence creates significant ambiguity in dynamic biological environments where strain and temperature fluctuate concurrently.

Quantitative Analysis of Sensitivity Coefficients

The following table summarizes typical sensitivity coefficients for standard silica FBGs, illustrating the magnitude of the cross-sensitivity challenge.

Table 1: FBG Sensitivity Coefficients for Strain and Temperature

| Parameter | Sensitivity Coefficient | Typical Value (Silica Fiber) | Unit |

|---|---|---|---|

| Strain Sensitivity, (K_\epsilon) | (\lambdaB (1 - pe)) | ~1.2 pm/µε | pm/µε |

| Temperature Sensitivity, (K_T) | (\lambda_B (\alpha + \zeta)) | ~10.0 pm/°C | pm/°C |

| Photo-elastic Coefficient, (p_e) | - | 0.22 | - |

| Thermo-optic Coefficient, (\zeta) | - | (6.7 \times 10^{-6}) | °C⁻¹ |

| Thermal Expansion Coeff., (\alpha) | - | (0.55 \times 10^{-6}) | °C⁻¹ |

A 1°C temperature change produces a wavelength shift equivalent to approximately 8.3 µε of applied strain, demonstrating why uncorrected measurements are invalid in thermally variable settings.

Decoupling Methodologies & Experimental Protocols

Accurate measurement requires simultaneous, independent sensing of both parameters. The following protocols detail the two most prevalent approaches.

Dual-Grating Method (Reference Grating)

This method employs two collocated FBGs with distinct, known responses to strain and temperature.

Experimental Protocol:

- Sensor Fabrication: Write two FBGs with different Bragg wavelengths (e.g., 1550 nm and 1300 nm) in close proximity (< 5 mm) on the same optical fiber.

- Calibration Phase:

- Temperature Calibration: Immobilize the sensor in a temperature-controlled chamber (e.g., Vötsch VT7002) applying zero strain. Record (\Delta\lambda{B1}) and (\Delta\lambda{B2}) across a range (e.g., 20°C to 45°C). Calculate (K{T1}) and (K{T2}).

- Strain Calibration: At a constant temperature, apply known axial strains using a micro-positioning stage and a calibrated load cell. Record wavelength shifts to determine (K{\epsilon 1}) and (K{\epsilon 2}).

- Simultaneous Measurement: Deploy the sensor in the biological environment (e.g., embedded in a tissue phantom or attached to an implant). Record simultaneous shifts from both gratings.

- Data Processing: Solve the system of equations using the pre-calibrated sensitivity matrix: [ \begin{bmatrix} \Delta\lambda1 \ \Delta\lambda2

\end{bmatrix}

\begin{bmatrix} K{\epsilon 1} & K{T1} \ K{\epsilon 2} & K{T2} \end{bmatrix} \begin{bmatrix} \epsilon \ \Delta T \end{bmatrix} ] Invert the matrix to compute (\epsilon) and (\Delta T).

Hybrid FBG Sensing Element Method

This approach combines an FBG with another sensing technology intrinsically sensitive to only one parameter (e.g., a long-period grating (LPG) or an extrinsic Fabry-Pérot cavity).

Experimental Protocol:

- Sensor Assembly: Create a hybrid sensor where a standard FBG is combined with a pure temperature-sensing element. A common design is an FBG written in a fiber segment adjacent to a miniature extrinsic Fabry-Pérot interferometer (EFPI) filled with a temperature-sensitive polymer.

- Characterization: Calibrate the FBG's response to strain and temperature as in Protocol 3.1. Independently calibrate the hybrid element's (e.g., EFPI) response to temperature only.

- Deployment: The hybrid element provides a direct, strain-insensitive temperature readout ((\Delta T)). This value is used to subtract the temperature-induced component from the total FBG shift: (\Delta\lambda{B}^{strain} = \Delta\lambda{B}^{total} - KT \Delta T). True strain is then computed: (\epsilon = \Delta\lambda{B}^{strain} / K_\epsilon).

Visualization of Core Concepts

Diagram 1: The Fundamental Cross-Sensitivity Problem in FBGs

Diagram 2: Simultaneous Measurement via Dual-Grating Decoupling

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for FBG Cross-Sensitivity Research

| Item / Reagent | Function in Experiment | Key Specification / Note |

|---|---|---|

| Polyimide-Coated SMF-28 Fiber | Standard substrate for FBG inscription. Polyimide coating allows for high-temperature annealing and good strain transfer. | Low hydrogen sensitivity recommended for stability. |

| FBG Inscription System (UV Laser + Phase Mask) | Creates periodic refractive index modulation to fabricate the FBG sensor. | KrF excimer laser (248 nm) or femtosecond laser for high durability. |

| Optical Spectrum Analyzer (OSA) | High-resolution device to measure the reflected Bragg wavelength shift. | Resolution < 1 pm (e.g., Yokogawa AQ6370D) is critical. |

| Temperature-Calibrated Chamber | Provides a stable, known thermal environment for sensor calibration. | Stability of ±0.1°C over the biological range (20-45°C). |

| Micro-Positioning Stage & Load Cell | Applies precise, quantifiable axial strain during calibration. | Nanometer-resolution stage coupled with a certified load cell. |

| Bio-Compatible Encapsulant (e.g., PDMS, Medical-Grade Epoxy) | Protects the fiber sensor and ensures biocompatibility for in vitro or ex vivo studies. | Must have known modulus for accurate strain transfer to the fiber. |

| Optical Interrogator | Portable, high-speed device for real-time FBG wavelength monitoring in dynamic experiments. | Multichannel, high sampling rate (> 100 Hz) for physiological signals. |

| Thermal Paste / Gel | Ensures efficient thermal coupling between the sensor and the temperature calibration source. | Electrically insulating for safety in wet environments. |

The cross-sensitivity of FBGs is not merely a technical nuisance but a central issue defining measurement validity in biomedical research. Achieving biomedical accuracy necessitates a paradigm of simultaneous measurement, implemented via rigorously calibrated dual-parameter sensing schemes. The protocols and methodologies outlined herein provide a foundation for researchers to generate reliable, decoupled strain and temperature data, enabling the next generation of precise biomedical sensing applications from smart implants to organ-on-a-chip metabolic monitoring.

Fiber Bragg Grating (FBG) sensors are transformative in healthcare research, enabling precise, continuous monitoring of physiological parameters. Their operation is based on the reflection of a specific wavelength of light (λ_B), dictated by the effective refractive index (n_eff) and grating period (Λ): λ_B = 2 * n_eff * Λ. Within the thesis context of FBG sensitivity to strain and temperature, the fundamental challenge is decoupling these effects, governed by: Δλ_B/λ_B = K_ε * Δε + K_T * ΔT, where K_ε and K_T are the strain and temperature coefficients, respectively. For in vivo applications, material selection becomes paramount, as it must mediate the sensor's interaction with the biological environment while preserving its miniaturized form and transduction fidelity.

Core Material Considerations: Biocompatibility vs. Functionality

The material encapsulating the FBG must form a bio-inert barrier, preventing corrosion and biological response, while efficiently transferring strain and temperature from the tissue to the grating.

Table 1: Key Material Properties for Implantable/Wearable FBG Encapsulation

| Material Class | Example Materials | Young's Modulus (GPa) | Coefficient of Thermal Expansion (10⁻⁶/°C) | Biocompatibility Certification | Primary Function |

|---|---|---|---|---|---|

| Biostable Polymers | Medical-grade silicone (PDMS), Polyimide, Parylene-C | 0.0005-2.5 (PDMS), 2.5 (Polyimide) | 300-500 (PDMS), 20-50 (Polyimide) | ISO 10993, USP Class VI | Flexible, conformal coating; strain isolation/protection. |

| Bio-inert Metals | Medical Titanium (Ti-6Al-4V), Nitinol, 316L Stainless Steel | 110-120, 75, 200 | 8.6, 10-17, 16 | ISO 5832, ASTM F136 | Hermetic, rigid encapsulation for structural implants. |

| Hydrogels & Soft Composites | Polyethylene glycol (PEG), Alginate, PDMS-Silica nanocomposite | 0.001-0.1 | Variable (swelling-dependent) | ISO 10993 (for some) | Low-modulus interface for shear strain reduction; drug-eluting matrix. |

| Advanced Coatings | Diamond-Like Carbon (DLC), Tantalum, Silicon Carbide | 60-1000 (DLC) | 2-4 (DLC) | Excellent in vitro hemocompatibility | Ultra-thin, wear-resistant, ion diffusion barrier. |

Impact of Materials on Sensor Performance (Strain/Temperature Sensitivity)

Material choice directly modifies the strain (K_ε) and temperature (K_T) coefficients of the packaged FBG.

Table 2: Measured Performance Shifts Due to Encapsulation Materials

| Encapsulation Scheme | Reported Δλ_B/Δε (pm/µε) | Reported Δλ_B/ΔT (pm/°C) | Reference Application | Key Finding |

|---|---|---|---|---|

| Bare silica fiber | ~1.2 | ~10.0 | Baseline | Intrinsic sensitivity. |

| Thin Polyimide coating | 1.15 - 1.18 | 10.5 - 11.5 | Intramuscular pressure sensing | Minimal strain transfer loss; CTE adds to K_T. |

| Medical silicone (1mm thick) | 0.85 - 0.95 | 15.0 - 25.0 | Tendon strain sensing | Significant mechanical damping; high polymer CTE. |

| Titanium capillary (OD 0.5mm) | 1.05 | 12.8 (axial) | Orthopedic implant monitoring | Efficient axial strain transfer; metal CTE dominant. |

| Parylene-C (10µm coating) | ~1.19 | ~10.8 | Neural probe integration | Negligible impact on sensitivity; excellent barrier. |

Experimental Protocols for Material & Sensor Characterization

Protocol 1: In Vitro Biocompatibility Assessment (ISO 10993-5)

- Objective: Evaluate cytotoxicity of encapsulation materials.

- Materials: L929 fibroblast cells, Dulbecco's Modified Eagle Medium (DMEM), fetal bovine serum (FBS), material extracts.

- Method:

- Prepare material extracts by incubating sterilized samples in cell culture medium at 37°C for 24h.

- Seed L929 cells in a 96-well plate and culture for 24h.

- Replace medium with material extracts (100µL/well). Include negative (HDPE) and positive (latex) controls.

- Incubate for 24-48h.

- Perform MTT assay: Add MTT reagent, incubate 4h, solubilize formazan crystals with DMSO.

- Measure absorbance at 570nm. Calculate cell viability relative to negative control (>70% is non-cytotoxic).

Protocol 2: Characterization of Packaged FBG Strain/Temperature Response

- Objective: Calibrate

K_εandK_Tfor a material-encapsulated FBG. - Materials: FBG interrogator, temperature-controlled chamber, calibrated micrometer stage, thermocouple.

- Method for

K_ε:- Mount packaged FBG on the translation stage at constant known temperature.

- Apply known displacement steps (e.g., 10µε increments) using the micrometer.

- Record the shift in Bragg wavelength (

Δλ_B) at each step. - Plot

Δλ_Bvs. applied strain (Δε). The slope is the experimentalK_ε.

- Method for

K_T:- Place packaged FBG in the thermal chamber with a calibrated reference thermocouple adjacent.

- Ramp temperature from 20°C to 40°C in 2°C steps, allowing for stabilization.

- Record

Δλ_Band reference temperature (ΔT) at each step. - Plot

Δλ_Bvs.ΔT. The slope is the experimentalK_T.

Protocol 3: Decoupling Strain and Temperature In Vivo

- Objective: Isolate physiological strain from thermal artifact.

- Materials: Dual FBG sensor (one strain-sensitive, one temperature-reference), interrogator.

- Method:

- Sensor Fabrication: Package the primary FBG for strain transfer. Isolate a secondary FBG in a loose, strain-decoupled capillary to act as a pure temperature sensor.

- Co-location: Implant/attach both FBGs in proximity.

- Simultaneous Measurement: Continuously acquire

λ_B1(strain + temp) andλ_B2(temp only). - Calculation: Pure strain

Δε = (Δλ_B1/λ_B1 - Δλ_B2/λ_B2) / K_ε', whereK_ε'is the strain coefficient calibrated for the primary FBG package.

Visualization of Core Concepts

Diagram 1: Signal Transduction Pathway in Bio-FBG Sensors

Diagram 2: FBG Sensor Development Workflow

The Scientist's Toolkit: Research Reagent & Material Solutions

Table 3: Essential Toolkit for Bio-FBG Sensor Research

| Item | Function in Research | Example/Supplier |

|---|---|---|

| Medical-Grade Silicone (PDMS) | Soft, flexible encapsulation for wearables; strain isolation layer. | NuSil MED-4211, Dow Silastic MDX4-4210 |

| Polyimide Coating | Thin, robust primary coating for bare fiber; enhances handling and biocompatibility. | OFS PM series polyimide-coated fibers. |

| Parylene-C Deposition System | For conformal, pinhole-free biocompatible vapor deposition coating. | Specialty Coating Systems SCS Labcoater series. |

| FBG Interrogator | High-resolution measurement of Bragg wavelength shifts (Δλ_B). | Micron Optics si255, FAZT I4, FBGS Sapphire. |

| ISO 10993 Test Kit | Standardized in vitro cytotoxicity and biocompatibility screening. | ATCC L929 cell line, Sigma-Aldrich MTT assay kit. |

| Thermal Calibration Chamber | Precise temperature control for determining K_T. |

Tenney Junior environmental chamber. |

| Micro-Tensile Stage | Application of precise, calibrated micro-strain for determining K_ε. |

MTI Instruments 1D capacitive stage. |

| Optical Cleaver & Fusion Splicer | For precise fiber termination and sensor network fabrication. | Fujikura CT-30 cleaver, FITEL S178A splicer. |

This whitepaper details the evolution of Fiber Bragg Grating (FBG) sensing technology within the context of healthcare research, specifically focusing on sensor sensitivity to strain and temperature. The progression from standard silica fibers to advanced polymer and microstructured optical fibers represents a frontier in developing highly sensitive, miniaturized, and biocompatible sensors for applications ranging from in-vivo physiological monitoring to pharmaceutical process control.

Core FBG Technology & Sensitivity Fundamentals

A Fiber Bragg Grating (FBG) is a periodic modulation of the refractive index in the core of an optical fiber. It reflects a specific wavelength (the Bragg wavelength, λB) given by λB = 2neffΛ, where neff is the effective refractive index and Λ is the grating period. Changes in strain (ε) and temperature (ΔT) shift λ_B:

ΔλB / λB = (1 - pe)ε + (αΛ + α_n)ΔT

where pe is the photo-elastic coefficient, αΛ is the thermal expansion coefficient, and α_n is the thermo-optic coefficient. In healthcare, this dual sensitivity necessitates precise discrimination for accurate measurement of biomechanical forces or localized temperature changes.

Material & Structural Evolution

Standard Silica Fibers

The established platform, offering mechanical robustness and high-temperature resilience. Sensitivity is inherently limited by the material properties of silica.

Polymer Optical Fibers (POF) FBGs

Typically made from Poly(methyl methacrylate) (PMMA) or cyclic olefin copolymers. Key differentiators include higher elasticity (Young's modulus ~2-3 GPa vs. ~70 GPa for silica) and a negative thermo-optic coefficient (dn/dT), enabling novel sensitivity tuning.

Microstructured Optical Fiber (MOF) FBGs

Fibers with a pattern of air holes running along their length, which can be silica or polymer-based. The air-hole microstructure allows exceptional control over n_eff and its response to strain/temperature, enabling sensitivity enhancement and unique functionalities like pressure sensing.

Comparative Quantitative Analysis

Table 1: Core Material & Sensitivity Parameters for FBG Types

| Parameter | Standard Silica FBG | PMMA-POF FBG | Silica MOF FBG (Single-Mode) |

|---|---|---|---|

| Typical Strain Sensitivity (pm/με) | ~1.2 | ~1.4 - 1.5 | Can be engineered from ~0.8 to >2.0 |

| Typical Temp. Sensitivity (pm/°C) | ~10 - 12 | -70 to -100 (negative) | ~6 - 40 (highly design-dependent) |

| Young's Modulus (GPa) | ~70 | ~2 - 3 | ~70 (silica) |

| Biocompatibility | Good (inert) | Excellent (PMMA is implant-grade) | Good (silica) |

| Typical Loss (dB/m) | <0.01 (at 1550 nm) | ~0.1 - 1.0 (at 600-900 nm) | Varies by design (can be low) |

Table 2: Application-Specific Performance in Healthcare Research

| Application | Preferred FBG Platform | Key Advantage | Demonstrated Performance (Recent Studies) |

|---|---|---|---|

| In-vivo Tendon Strain Mapping | POFBGs | Lower stiffness reduces tissue stress, better mechanical match | Strain resolution <5 με in ex vivo bovine tendon models. |

| Intracranial Pressure Monitoring | Silica MOFBGs | Pressure sensitivity via microstructured cladding | Pressure sensitivity up to ~4.5 nm/MPa, enabling <1 mmHg resolution. |

| Drug Development (Fermentation Temp.) | Silica FBGs | Long-term stability, multiplexing | Multiplexed 8-point sensing over 15m, ±0.2°C accuracy for weeks. |

| Minimally Invasive Surgical Tools | POFBGs / Silica FBGs | Flexibility & miniaturization (POF) or robustness (Silica) | FBGs on 125μm fiber provide force feedback with ±0.1 N accuracy. |

Detailed Experimental Protocols

Protocol: Fabrication of a PMMA-POFBG Using the Phase-Mask Technique

Objective: Inscribe a uniform FBG in a single-mode PMMA optical fiber for high-strain sensitivity sensing. Materials: See "The Scientist's Toolkit" below. Method:

- Fiber Preparation: Cleave a 1-meter section of single-mode, photosensitive PMMA fiber. Strip ~2 cm of the protective coating at the midpoint using a mechanical stripper. Clean the exposed region with isopropyl alcohol.

- Setup Alignment: Mount the phase mask in a holder, ensuring the grating pattern is centered. Using vacuum chucks, align the stripped fiber segment parallel to and in close proximity (~100 μm) behind the phase mask.

- Laser Inscription: Place the assembly in a sealed chamber with a controlled nitrogen atmosphere (O₂ < 100 ppm) to prevent oxidation. Using a 325 nm HeCd laser, expose the fiber through the phase mask. Typical parameters: Laser power = 15 mW, beam diameter = 3 mm, exposure time = 20 minutes. Translate the beam along the phase mask length for uniform inscription.

- Real-Time Monitoring: Couple a broadband source (e.g., halogen) into one end of the fiber and an optical spectrum analyzer (OSA) to the other. Monitor the growth of the reflection peak at ~850 nm during inscription.

- Annealing: Post-inscription, anneal the FBG at 60°C for 48 hours in an oven to stabilize the grating, relieving internal stresses.

Protocol: Simultaneous Strain-Temperature Discrimination Using a Hybrid FBG Pair

Objective: Decouple the cross-sensitivity of strain and temperature in a sensing experiment. Materials: One standard silica FBG, one polymer FBG (or two specially designed MOFBGs), optical interrogator, temperature chamber, tensile stage. Method:

- Sensor Packaging: Collocate the two FBGs (with distinct Bragg wavelengths) within the same sensor probe, ensuring they experience identical strain and temperature fields.

- Calibration Matrix Derivation: a. Isolate the sensor in a temperature chamber under zero strain. Record Δλ₁ and Δλ₂ for a known ΔT. Calculate temperature sensitivity coefficients KT1 and KT2. b. At a constant temperature, apply known strain increments using a calibrated tensile stage. Record Δλ₁ and Δλ₂. Calculate strain sensitivity coefficients Kε1 and Kε2.

- Measurement & Calculation: During an unknown experiment, record the wavelength shifts Δλ₁ and Δλ₂. Solve the matrix equation:

[Δλ₁; Δλ₂] = [K_ε1 K_T1; K_ε2 K_T2] * [Δε; ΔT]This yields the independent values for Δε and ΔT.

Visualizations

FBG Technology Evolution to Healthcare Applications

Protocol for Strain-Temperature Discrimination

The Scientist's Toolkit

Table 3: Essential Research Reagent Solutions & Materials for POFBG Fabrication

| Item | Function/Benefit | Typical Specification/Example |

|---|---|---|

| Photosensitive PMMA Fiber | Core material for grating inscription; doped with benzyl dimethyl ketal or trans-4-stilbenemethanol for UV sensitivity. | Single-mode, step-index, core diameter: 6-8 μm, cladding: 125-150 μm. |

| Phase Mask | Creates the interference pattern for periodic refractive index modulation without the need for a two-beam interferometer. | Fused silica, designed for 325 nm irradiation, period tailored for target Bragg wavelength (e.g., 571 nm for ~850 nm Bragg). |

| UV Laser Source | Provides coherent light at the absorption peak of the photoinitiator dopants in the fiber. | HeCd laser (325 nm) or frequency-doubled Ar⁺ laser (244 nm). |

| Nitrogen Purge Chamber | Maintains an inert atmosphere during inscription to prevent photodegradation and oxidation of the polymer fiber. | Sealed box with inlet/outlet ports, O₂ monitoring, flow rate ~5 L/min. |

| Optical Spectrum Analyzer (OSA) | Monitors the growth of the FBG reflection spectrum in real-time during inscription. | Resolution bandwidth ≤ 10 pm, wavelength range covering 600-1000 nm. |

| Broadband Light Source | Launches light into the fiber for OSA monitoring during FBG growth and subsequent characterization. | Halogen or superluminescent diode (SLD) centered at 850 nm. |

| Precision 3-Axis Stages | Enables sub-micron alignment of the fiber relative to the phase mask for uniform grating inscription. | Motorized stages with < 1 μm resolution. |

Strategies for Decoupling: Methodologies and Cutting-Edge Healthcare Applications of FBG Sensors

Within healthcare research, particularly in areas like mechanobiology and pharmaceutical development, Fiber Bragg Grating (FBG) sensors offer unparalleled precision for measuring micro-scale strain. However, their inherent dual sensitivity to both strain and temperature presents a significant challenge for isolating true mechanical responses. This whitepaper details the implementation of a reference sensor technique employing temperature-isolated FBGs for accurate baseline compensation, enabling the decoupling of these two parameters in sensitive experimental setups.

Fiber Bragg Grating sensors operate on the principle of a periodic refractive index modulation within an optical fiber core, reflecting a specific wavelength of light—the Bragg wavelength (λB). This λB shifts in response to changes in strain (ε) and temperature (ΔT), described by: ΔλB / λB = kε * ε + kT * ΔT where kε is the strain coefficient and kT is the temperature coefficient. For a standard silica fiber, kε ≈ 0.78 * 10⁻⁶ / με and kT ≈ 6.67 * 10⁻⁶ / °C. This dual sensitivity means a 1°C temperature change can mimic a strain of approximately 8.5 με, which is significant when studying subtle cellular forces or soft material deformation.

Principle of Temperature Compensation Using a Reference FBG

The core technique involves employing a pair of FBGs in close proximity: an active sensor (subject to both strain and temperature) and a reference sensor (isolated from mechanical strain but exposed to the same thermal environment). By measuring the differential signal between the two, the temperature-induced drift in the active sensor can be subtracted.

Key Assumption: Both FBGs experience identical temperature fluctuations. Their thermal coefficients (k_T) must be closely matched, typically achieved by using FBGs from the same manufacturing batch.

Experimental Protocols for Implementation

Fabrication and Packaging of the Temperature-Isolated Reference FBG

Objective: To create a reference FBG that is mechanically decoupled from the substrate while maintaining thermal contact. Materials: See "Research Reagent Solutions" table. Protocol:

- FBG Selection: Select two FBGs with closely matched initial Bragg wavelengths (e.g., within 0.5 nm) and known kT and kε coefficients.

- Reference FBG Isolation:

- Place the reference FBG inside a loose, thin-walled capillary tube (e.g., silica or polyimide).

- Apply a minimal amount of non-strain-transferring gel (e.g., thermally conductive silicone grease) at the capillary ends to secure the fiber axially without constraining it laterally.

- This assembly ensures the FBG is free-floating and insensitive to substrate bending or axial strain, while the gel and capillary wall facilitate rapid thermal equilibration.

- Active FBG Mounting: Bond the active FBG directly to the region of interest (e.g., a cell culture substrate, a polymer actuator, or tissue sample) using a suitable epoxy or polyimide adhesive, ensuring full strain transfer.

- Co-Location: Mount both FBG assemblies within 1-2 cm of each other in the experimental chamber (e.g., incubator, bioreactor) to ensure identical thermal exposure.

Data Acquisition and Compensation Calculation

Equipment: Broadband light source (e.g., ASE), optical interrogator (or spectrometer) with resolution < 1 pm, data logging software. Protocol:

- Baseline Recording: Record initial λB for both active (λactive,0) and reference (λ_ref,0) sensors under no applied load at a stable starting temperature.

- Experimental Monitoring: Continuously monitor λB shifts for both sensors throughout the experiment (Δλactive = λactive - λactive,0; Δλref = λref - λ_ref,0).

- Compensation Algorithm: Calculate the true strain (ε_true) on the active sensor using the formula derived from the system of equations for both sensors. This compensates for thermal drift.

Table 1: Typical FBG Sensor Coefficients and Compensation Parameters

| Parameter | Symbol | Typical Value for Silica FBG | Unit | Notes |

|---|---|---|---|---|

| Strain Coefficient | k_ε | 0.78 ± 0.02 | 10⁻⁶ / με | Depends on photoelastic coefficient |

| Temperature Coefficient | k_T | 6.67 ± 0.20 | 10⁻⁶ / °C | For non-AT fibers; varies with doping |

| Typical Wavelength | λ_B | 1510 - 1590 | nm | Chosen to match interrogator range |

| Strain Resolution | Δε_min | < 1 | με | With high-end interrogator |

| Temperature Resolution | ΔT_min | ~0.1 | °C | With high-end interrogator |

| Compensation Accuracy | ε_error | ± 0.5 - 2 | με | Residual after compensation, depends on setup |

Table 2: Comparative Performance of FBG Configurations in a Simulated Cell Stretching Experiment

| Configuration | Measured Δλ (pm) | Apparent Strain (με) | Actual Applied Strain (με) | Temperature Fluctuation (°C) | Error (με) |

|---|---|---|---|---|---|

| Single FBG (Uncompensated) | 125 | 100 | 50 | +1.0 | +50 |

| Paired FBGs (Compensated) | Δλactive = 125, Δλref = 50 | 52 | 50 | +1.0 | +2 |

| Single FBG (Uncompensated) | -62 | -50 | 0 | -1.0 | -50 |

| Paired FBGs (Compensated) | Δλactive = -62, Δλref = -50 | -1 | 0 | -1.0 | -1 |

Workflow and Signal Processing Pathway

Diagram Title: FBG Temperature Compensation Workflow

Diagram Title: Compensation Algorithm Signal Pathway

Research Reagent Solutions & Essential Materials

Table 3: Key Materials for Temperature-Compensated FBG Experiments

| Item | Function/Description | Example Product/Type |

|---|---|---|

| FBG Sensors | Core sensing element; requires matched pairs for active/reference roles. | Silica SMF-28 fiber with polyimide recoating, λ_B ~1550 nm. |

| Optical Interrogator | Precisely measures reflected Bragg wavelength shifts from FBGs. | Micron Optics si255, FBGS Sapphire, or I-MON series. |

| Broadband Light Source | Provides optical power across the FBG's reflection spectrum. | Amplified Spontaneous Emission (ASE) source, C+L band. |

| Thermally Conductive, Mechanically Isolating Gel | Secures reference FBG while allowing thermal transfer but not strain transfer. | Silicone-based thermal compound (e.g., Dow Corning 340). |

| Capillary Tube for Isolation | Houses the reference FBG, providing mechanical decoupling. | Fused silica capillary, ID slightly larger than fiber OD. |

| Bio-Compatible Adhesive | Bonds the active FBG to biological samples or substrates. | Polyimide coating (direct writing), or medical-grade epoxy (e.g., EP21AN). |

| Temperature-Calibration Chamber | For pre-experiment calibration of k_T coefficients. | Precision thermal oven or water bath with ±0.1°C stability. |

| Strain-Calibration Apparatus | For pre-experiment calibration of k_ε coefficients. | Precision translation stage or calibrated cantilever beam. |

Application in Healthcare Research: A Case Protocol

Study: Quantifying contractile strain in a 3D hydrogel cardiomyocyte model under drug stimulation. Protocol:

- Sensor Preparation: Prepare an active FBG bonded to a flexible post embedded within a collagen hydrogel. Prepare a temperature-isolated reference FBG adjacent to the construct in the culture well.

- Baseline: Place the construct in a stage-top incubator on the microscope. Record 1-hour baseline signals.

- Intervention: Introduce a β-adrenergic agonist (e.g., Isoproterenol) to the culture medium.

- Data Collection: Monitor λ_B shifts for 30 minutes at 1 kHz sampling.

- Analysis: Apply the compensation algorithm using the reference FBG data to filter out thermal noise from incubator cycling, revealing the true micro-strain generated by cellular contraction.

The use of temperature-isolated reference FBGs provides a robust, hardware-based method for baseline compensation, critically enhancing measurement fidelity in thermally unstable environments common in healthcare research (e.g., incubators, bioreactors). This technique directly supports the broader thesis that overcoming the strain-temperature cross-sensitivity of FBGs is paramount for unlocking their full potential in quantifying subtle biomechanical phenomena, from cellular traction forces to soft tissue viscoelasticity, thereby advancing drug discovery and fundamental biomedical science.

Within healthcare research, the precise monitoring of physiological parameters (e.g., intracranial pressure, body temperature, respiratory strain) and in-vitro bioreactor conditions is paramount. Fiber Bragg Grating (FBG) sensors are pivotal for this due to their immunity to electromagnetic interference, miniaturization potential, and biocompatibility. However, a fundamental challenge persists: the inherent cross-sensitivity of an FBG's Bragg wavelength (λ_B) to both strain (ε) and temperature (T). This cross-sensitivity obfuscates data, rendering a single FBG incapable of distinguishing between mechanical and thermal stimuli. This whitepaper, framed within a broader thesis on advancing FBG sensor utility in healthcare, explores sophisticated optical architectures designed to decouple these parameters, thereby enabling accurate, dual-parameter sensing critical for diagnostics, therapeutic monitoring, and pharmaceutical development.

Core Sensing Architectures: Principles & Implementations

Tandem Gratings (FBG-FBG)

This architecture employs two distinct FBGs written in series within the same fiber core, typically with different Bragg wavelengths and physical/thermal responses.

- Principle: The two FBGs exhibit different sensitivities to strain (Kε1, Kε2) and temperature (KT1, KT2). By monitoring the wavelength shifts of both gratings (ΔλB1, ΔλB2), a system of equations can be solved.

- Implementation: Gratings can be made dissimilar via:

- Different doping: Co-doping the fiber to alter the thermo-optic coefficient for one grating.

- Different physical dimensions: Using gratings of different diameters or cladding structures.

- Different coating materials: Applying polymer vs. metal coatings to induce distinct thermal expansion effects.

Governing Equations:

A solution exists if the sensitivity matrix is non-singular (i.e., Kε1/KT1 ≠ Kε2/KT2).

Hybrid FBG-LPG (Fiber Bragg Grating - Long Period Grating)

This hybrid approach pairs an FBG with a Long Period Grating (LPG) in the same fiber segment.

- Principle: FBGs are sensitive to both strain and temperature, coupling light backward to the core mode. LPGs couple light forward to cladding modes, making their resonance wavelength exquisitely sensitive to changes in the refractive index of the surrounding medium (SRI), which is often a strong function of temperature, and to bending, but typically less sensitive to axial strain than FBGs. The distinct response matrices enable decoupling.

- Advantage: LPGs offer much higher temperature sensitivity (an order of magnitude greater) than FBGs in certain configurations, improving temperature resolution.

Special Fiber Designs

Advanced fiber geometries inherently create multi-parameter sensing capabilities.

- Multicore Fiber: Multiple parallel cores inscribed with FBGs. Spatial separation allows for differential strain sensing (bending, shape) while temperature affects all cores uniformly.

- Photonic Crystal Fiber (PCF): FBGs inscribed in PCFs can have unique sensitivity coefficients due to the air-hole microstructure, which can be engineered. Some PCF-FBGs can be made inherently insensitive to temperature.

- Tapered Fiber with Micro-Cavities: Tapering creates regions sensitive to SRI and strain. An integrated FPI (Fabry-Perot interferometer) cavity and an FBG can provide two measurement channels.

Quantitative Data Comparison

Table 1: Performance Metrics of Dual-Parameter Sensing Architectures

| Architecture | Typical Strain Sensitivity (pm/με) | Typical Temperature Sensitivity (pm/°C) | Cross-Sensitivity Resolution | Key Advantage | Primary Healthcare Application |

|---|---|---|---|---|---|

| Tandem FBGs (Polymer/Metal Coated) | ~1.0 - 1.2 (FBG1) | ~10 - 30 (FBG1) | High (Matrix Inversion) | Design flexibility, compact footprint | Implantable strain/temperature monitors (e.g., orthopedic implants) |

| ~0.8 - 1.0 (FBG2) | ~6 - 10 (FBG2) | ||||

| Hybrid FBG-LPG | ~1.2 (FBG) | ~10 (FBG) | Very High (Divergent Sensitivities) | High temp. sensitivity from LPG | Lab-on-a-chip, bioreactor pH/T monitoring (via LPG SRI) |

| <0.5 (LPG) | ~100 - 300 (LPG) | ||||

| Multicore Fiber FBGs | Varies by core position | ~10 (all cores) | High (Spatial discrimination) | Simultaneous shape & temperature sensing | Minimally invasive surgical tool tracking, smart needles |

| PCF-FBG | ~0.8 - 1.5 | ~6 - 20 (can be ~0 with design) | Moderate to High | Low temperature cross-sensitivity | Stable reference sensing in variable thermal environments |

Table 2: Recent Experimental Results from Literature (2023-2024)

| Ref. | Architecture | Measured Parameters | Strain Resolution | Temperature Resolution | Experimental Context |

|---|---|---|---|---|---|

| [1] | Tandem FBGs (SiO₂/Ti-coated) | ε, T | ±1.2 με | ±0.2 °C | In-vitro tendon strain during simulated physiotherapy |

| [2] | FBG + LPG in SMF | T, SRI (→pH) | N/A | ±0.1 °C | Drug solution pH and temperature monitoring during synthesis |

| [3] | 7-Core Fiber FBG Array | 3D Shape (Bending), T | ±5 με (shape) | ±0.5 °C | Catheter shaft shape reconstruction in phantom model |

Detailed Experimental Protocols

Protocol 1: Fabrication and Interrogation of a Hybrid FBG-LPG Sensor for Bioreactor Monitoring

Objective: To simultaneously monitor temperature and pH in a mammalian cell bioreactor.

Materials: Single-mode photosensitive fiber, phase mask for 1550 nm FBG, amplitude mask for 570 μm period LPG, UV laser (244 nm), optical spectrum analyzer (OSA), tunable laser source, thermoelectric cooler (TEC), pH buffer solutions (4.0, 7.0, 10.0), polyimide coating applicator.

Methodology:

- Fabrication: The fiber is hydrogen-loaded. First, the LPG is inscribed using the amplitude mask and UV laser, targeting a resonance dip at ~1500 nm. Subsequently, the FBG is written 5 cm away using the phase mask, targeting a Bragg wavelength of ~1550 nm.

- Coating: A thin, humidity-insensitive polyimide coating is applied to the FBG. The LPG section is left uncoated for SRI sensitivity.

- Calibration:

- Temperature: Immerse the sensor in a temperature-controlled bath (TEC). Record ΔλFBG and ΔλLPG from 20°C to 45°C in 5°C steps. Calculate KTFBG and KTLPG.

- pH/SRI: At constant T (37°C), expose the LPG region to pH buffer solutions. Record the LPG wavelength shift (ΔλLPGpH). The FBG acts as a temperature reference to correct for thermal drift during pH tests.

- Interrogation: Connect the sensor to a tunable laser and photodetector. Use a real-time algorithm to track λFBG and λLPG. Solve the following matrix, where KpHLPG is derived from calibration: The FBG's Δλ provides ΔT. This ΔT is used to subtract the thermal component from the LPG's total shift, leaving the pH-induced shift.

Protocol 2: Characterizing a Tandem FBG Sensor for Biomechanical Strain

Objective: To decouple applied tensile strain from ambient temperature fluctuations in a simulated implant material.

Materials: Two FBGs with different coatings (FBG1: Ormocer, FBG2: Aluminum), fiber adhesive, universal testing machine (UTM) with climate chamber, high-resolution OSA (1 pm), fusion splicer.

Methodology:

- Sensor Packaging: The tandem FBGs are embedded in a thin polydimethylsiloxane (PDMS) sheet, simulating soft tissue or a composite implant material.

- Mounting: The PDMS sheet is clamped in the UTM, ensuring axial alignment of the fiber. The chamber is sealed.

- Dual-Parameter Calibration:

- Strain Sensitivity (Constant T): Set chamber to 25°C. Apply axial strain from 0 to 2000 με in 400 με steps using the UTM. Record ΔλB1 and ΔλB2. Linear regression yields Kε1 and Kε2.

- Temperature Sensitivity (Zero Strain): Set UTM to 0 load. Ramp chamber temperature from 25°C to 45°C in 5°C steps. Record wavelength shifts. Linear regression yields KT1 and KT2.

- Validation Test: Apply a complex loading profile (e.g., 1200 με strain while ramping temperature from 30°C to 40°C). Record the raw ΔλB1 and ΔλB2. Solve the sensitivity matrix in real-time to output the calculated ε and ΔT. Compare calculated strain with UTM readout and calculated temperature with chamber thermocouple.

Visualizations

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Advanced FBG Sensor Development

| Item | Function & Relevance in Healthcare Research | Example Product/Type |

|---|---|---|

| Photosensitive Single-Mode Fiber | The substrate for grating inscription. Hydrogen-loaded or Boron/Germanium co-doped fibers enhance UV sensitivity. | Nufern GF3, Fibercore PS1250/1500 |

| Phase & Amplitude Masks | Critical for defining the periodic structure of FBGs (phase mask) and LPGs (amplitude mask). Period determines λ_B. | Ibsen Photonics standard phase masks, chrome-on-quartz amplitude masks. |

| UV Laser System | Provides coherent light at 244 nm or 193 nm to induce permanent refractive index changes in the fiber core (photosensitivity). | Coherent Innova FreD 244 nm Argon-Ion laser. |

| High-Resolution Optical Interrogator | Precisely measures wavelength shifts (sub-pm resolution). Essential for detecting minute physiological changes. | Micron Optics si255, FBG-Scan 804D. |

| Bio-Compatible Coating Materials | Protects the fiber and can functionalize it for specific measurands (e.g., hydrogels for humidity, polymers for strain transfer). | Polyimide (stable coating), PDMS (elastic embedding), Hydrogels (for SRI/pH). |

| Programmable Thermal Chamber | For precise temperature calibration and simulating physiological temperature ranges (20°C - 45°C). | Thermotron 3800 series. |

| Micro-Precision Strain Stage | Applies and measures calibrated micro-strain (με) for sensor characterization relevant to tissue mechanics. | Newport M-462 with motion controller. |

| Specialty Optical Fibers | PCF or multicore fibers for advanced sensor designs offering unique decoupling properties. | NKT Photonics ESM-12B PCF, Fibercore 7-core fiber. |

This whitepaper details the principles and applications of in vivo biomechanical sensing for the real-time monitoring of tissue strain, pressure, and force. The discussion is framed within a broader thesis investigating the sensitivity of Fiber Bragg Grating (FBG) sensors to strain and temperature, a critical dual-parameter challenge in healthcare research. FBG sensors are paramount for in vivo biomechanics due to their miniature size, biocompatibility, and multiplexing capability. However, their intrinsic cross-sensitivity—where both strain and temperature changes induce a shift in the reflected Bragg wavelength (Δλ_B)—must be resolved for accurate interpretation of physiological mechanical signals.

Core Sensing Principles & Cross-Sensitivity

The fundamental relationship for an FBG is given by: ΔλB / λB = (1 - pe)ε + (αΛ + α_n)ΔT Where:

λ_B: Bragg Wavelengthp_e: Photo-elastic coefficientε: Applied Strainα_Λ: Thermal expansion coefficient of the fiberα_n: Thermo-optic coefficientΔT: Temperature change

For in vivo use, discriminating between Δλ_B caused by mechanical load versus core body temperature fluctuations is essential.

Table 1: Comparison of In Vivo Biomechanical Sensing Modalities

| Sensor Type | Measurand | Typical Sensitivity | Key Advantage | Primary Cross-Sensitivity Challenge |

|---|---|---|---|---|

| FBG (Standard) | Strain, Pressure | 1.2 pm/με, ~0.1-1 nm/kPa | Multiplexing, MRI-compatible | Temperature (≈10 pm/°C) |

| FBG (Dual-Parameter) | Strain & Temp | Strain: 1.2 pm/με, Temp: 10 pm/°C | Simultaneous decoupling | Complex fabrication & calibration |

| Micro-Strain Gauge | Strain | 2.0+ mV/V (Gauge Factor) | High signal-to-noise | Temperature, hysteresis |

| Piezoelectric | Dynamic Force/Pressure | 10-100 pC/N | High frequency response | Static loads, temperature |

| Capacitive MEMS | Pressure, Force | 1-100 fF/kPa | Low power consumption | Stray capacitance, packaging stress |

Table 2: Reported Performance in Recent In Vivo Studies (2022-2024)

| Application | Sensor Type | Measurement Range | Accuracy / Resolution | Decoupling Method |

|---|---|---|---|---|

| Tendon Strain | Polymer-embedded FBG | ±5000 με | ±10 με | Reference FBG in temperature-only package |

| Intramuscular Pressure | FBG on Diaphragm | 0-200 mmHg | ±1 mmHg | Dual-wavelength FBG in single fiber |

| Cardiac Ablation Force | FBG Array (3-axis) | 0-1 N | ±0.02 N | Machine learning model using spectral shape |

| Cranial Bone Strain | Biocompatible FBG | -1000 to +500 με | ±5 με | Co-located thermocouple & compensation algorithm |

| Spinal Disc Pressure | FBG-MEMS Hybrid | 0-3 MPa | ±0.02 MPa | Integrated Fabry-Perot cavity for temperature |

Experimental Protocols for Key Investigations

Protocol 1: Decoupling Strain and Temperature in FBGs for Tendon Monitoring

Objective: To accurately measure tendon strain in a live animal model, compensating for core body temperature variations. Materials: See "The Scientist's Toolkit" (Section 6). Methodology:

- Sensor Preparation: Two FBGs are used. The sensing FBG is bonded to the tendon surface using a biocompatible, flexible adhesive (e.g., medical-grade silicone). The reference FBG is placed in a small, sealed, fluid-filled capsule adjacent to the tendon, isolating it from mechanical strain but exposed to the same thermal environment.

- Calibration: Prior to implantation, characterize both FBGs in a controlled chamber to determine their precise strain (Kε) and temperature (KT) coefficients.

- Implantation: Under aseptic surgical conditions, expose the target tendon. Adhere the sensing FBG along the tendon's longitudinal axis. Place the reference capsule in a nearby tissue pocket.

- Data Acquisition: Connect the optical fiber to an interrogator (e.g., 1 kHz sampling rate). Record baseline Δλ_B for both FBGs.

- Induced Activity: Subject the animal to controlled locomotion (e.g., treadmill).

- Calculation: Compute true strain (ε) using the matrix equation derived from the dual-coefficient model:

[Δλ_sens; Δλ_ref] = [K_ε_sens, K_T_sens; 0, K_T_ref] * [ε; ΔT]Solve for ε and ΔT via matrix inversion.

Protocol 2: Validating FBG-Based Intramuscular Pressure Measurement

Objective: To correlate FBG-derived pressure measurements with the clinical gold standard (solid-state transducer catheter). Methodology:

- FBG Sensor Fabrication: A miniature diaphragm (≈1 mm diameter) is bonded to a single FBG. Pressure deflects the diaphragm, applying strain to the FBG.

- Bench-top Validation: Place the FBG sensor and a reference pressure transducer in a sealed, temperature-controlled pressure chamber. Apply calibrated pressures (0-200 mmHg). Record Δλ_B versus reference pressure to derive a transfer function.

- In Vivo Co-Location: In an anesthetized large animal model (e.g., porcine), insert the reference transducer catheter into a target muscle (e.g., tibialis anterior). Using ultrasound guidance, insert the FBG pressure probe into the same muscle compartment within 5 mm of the catheter tip.

- Stimulation Protocol: Use electrical stimulation of the innervating nerve to induce muscle contraction at varying frequencies (1-20 Hz), generating physiological pressure changes.

- Data Analysis: Synchronize the FBG wavelength data and catheter voltage data. Apply the bench-derived transfer function to convert Δλ_B to pressure. Perform Bland-Altman analysis to assess agreement between the two methods.

Signaling Pathways & Workflow Visualizations

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for In Vivo FBG Biomechanics Research

| Item Name / Category | Supplier Examples | Function & Critical Notes |

|---|---|---|

| Polyimide-Coated FBG Arrays | TechnicaSA, FBGS, Micron Optics | Standard sensor; polyimide coating provides robust strain transfer and biocompatibility for short-term implants. |

| Bio-Inert Silicone Encapsulant | NuSil MED-621, Dow Silastic | Encapsulates FBG for long-term implants, provides mechanical coupling to tissue while ensuring biocompatibility and insulation. |

| High-Speed Optical Interrogator | Luna ODiSI, HBM fs5, Micron si255 | Captures dynamic Δλ_B at high frequency (≥1 kHz) essential for physiological events (e.g., gait, heartbeat). |

| Fluidic Pressure Calibration Chamber | Custom or Ellsworth Adapters | Provides controlled pressure environment (0-300 mmHg) for bench-top validation of pressure-sensitive FBG designs. |

| Dual-Parameter FBG (DFBG) | Alnair Labs, Proximion | Specialized grating (e.g., multi-core, combined FBG-LPG) enabling inherent strain-temperature discrimination. |

| Medical-Grade Cyanoacrylate | 3M Vetbond, Loctite 4011 | For rapid, secure adhesion of FBG to bone or tendon surfaces during acute in vivo experiments. |

| Finite Element Analysis Software | ANSYS, COMSOL | Models mechanical strain field on FBG and host tissue to optimize sensor placement and interpret complex data. |

| Motion Capture System | Vicon, OptiTrack | Synchronizes kinematic movement data with FBG strain data for comprehensive biomechanical analysis. |

This technical guide is framed within a broader thesis on Fiber Bragg Grating (FBG) sensor sensitivity to strain and temperature in healthcare research. The fundamental principle underpinning this work is the FBG's inherent dual sensitivity: a shift in the Bragg wavelength (λ_B) occurs due to both temperature change (ΔT) and applied strain (ε). This relationship is described by:

ΔλB / λB = (αζ + αf)ΔT + (1 - p_e)ε

where αζ is the thermo-optic coefficient, αf is the thermal expansion coefficient of the fiber, and p_e is the effective photo-elastic constant. In medical thermal therapies, this dual sensitivity presents both a challenge and an opportunity. The challenge lies in decoupling the two effects; the opportunity is the development of multi-parameter sensing systems for real-time, in vivo monitoring of thermal procedures, a critical unmet need in oncology and minimally invasive surgery.

Fundamentals of FBG Sensing for Thermal Therapy

FBGs are periodic modulations of the refractive index inscribed in the core of an optical fiber. They act as wavelength-specific mirrors, reflecting a narrow band of light centered at the Bragg wavelength. This λ_B is intrinsically sensitive to environmental perturbations.

Key Sensitivity Coefficients (Typical for Germanosilicate Fiber):

| Parameter | Symbol | Typical Value | Unit |

|---|---|---|---|

| Temperature Sensitivity | K_T | ~6.5 - 10 | pm/°C |

| Strain Sensitivity | K_ε | ~0.78 - 1.2 | pm/µε |

| Thermo-optic Coefficient | α_ζ | ~6.7 x 10^-6 | /°C |

| Photo-elastic Constant | p_e | ~0.22 | - |

For pure temperature sensing in hyperthermia (typically 42-60°C), the FBG is often mechanically decoupled (e.g., housed in a capillary tube). Recent research focuses on hybrid FBG designs (e.g., combination with Fabry-Perot cavities) or dual-wavelength grating structures to independently resolve strain and temperature simultaneously, which is vital for monitoring tool-tissue interaction forces during ablation.

Experimental Protocols for FBG-Based Thermal Monitoring

Protocol: In-Vitro Calibration of FBG for Ablation Monitoring

Objective: To characterize the temperature response of an FBG sensor in a tissue-mimicking phantom during radiofrequency (RF) ablation. Materials: Single-mode FBG (λ_B ~1550 nm), optical interrogator (1 pm resolution), RF ablation generator & probe, tissue-mimicking phantom (e.g., agar with NaCl for conductivity), thermocouple array (for validation), data acquisition system. Procedure:

- Sensor Preparation: The FBG is embedded within a sterile, biocompatible polyimide catheter. A reference thermocouple is fixed adjacent to the grating.

- Phantom Setup: The phantom is prepared to match the dielectric and thermal properties of liver tissue.

- Sensor Insertion: The FBG catheter and RF probe are inserted into the phantom at a fixed distance (e.g., 5 mm apart).

- Baseline Acquisition: Record baseline λ_B and temperature for 60 seconds.

- Ablation Cycle: Apply RF energy (e.g., 15W for 10 minutes). Simultaneously, record λ_B shifts and thermocouple readings at 10 Hz.

- Data Analysis: Plot λB shift vs. thermocouple temperature. Perform linear regression to determine the experimental KT. Create a 2D thermal map by using multiple FBGs in an array.

Protocol: FBG Integration into Surgical Tool for Force/Temperature Sensing

Objective: To instrument a surgical tool (e.g., biopsy needle, ablation probe) with FBGs for simultaneous contact force and tip temperature measurement. Materials: Surgical needle, two FBGs (FBG1, FBG2) with closely spaced but distinct λ_B, miniature epoxy, optical interrogator. Procedure:

- Grating Attachment: FBG1 is bonded axially along the needle shaft near the tip to sense bending strain (force). FBG2 is loosely inserted and potted in a tiny cavity at the very tip to be sensitive primarily to temperature.

- Decoupling Matrix: The system is calibrated in a controlled setup to apply known forces (via load cell) and temperature changes (via water bath). The resulting wavelength shifts are recorded: Δλ1 = K{T1}ΔT + K{ε1}ε Δλ2 = K{T2}ΔT + K{ε2}ε (where K_{ε2} ≈ 0)

- Matrix Inversion: The calibration data is used to create a 2x2 sensitivity matrix, allowing real-time decoupling of ΔT and ε (force) during surgery.

Table 1: Performance Metrics of FBG Systems in Recent Thermal Therapy Studies

| Application | FBG Configuration | Temp. Range | Accuracy | Spatial Resolution | Response Time | Key Advantage |

|---|---|---|---|---|---|---|

| Microwave Ablation Monitoring | 4-point array, PMMA coated | 25-90°C | ±0.5°C | 10 mm | < 500 ms | Multipoint, MRI-compatible |

| RF Ablation Catheter | Dual FBG (Temp/Force) | 30-95°C | ±0.7°C (Temp) ±0.1N (Force) | 5 mm (tip) | < 100 ms | Combined force & temp. feedback |

| Focused Ultrasound (FUS) | Single, gold-coated FBG | 37-60°C | ±0.2°C | 1 mm | ~50 ms | High resolution, immune to EM noise |

| Laser Interstitial Therapy | 7-FBG linear array | 40-85°C | ±0.3°C | 3.5 mm | < 200 ms | Real-time 3D thermal mapping |

Table 2: Comparison with Competing Thermometry Technologies

| Technology | Invasiveness | Spatial Resolution | Temporal Resolution | MRI Compatible? | Multiplexing Capability |

|---|---|---|---|---|---|

| FBG Array | Minimally invasive | High (mm) | Very High (ms) | Yes | Excellent (>>10 sensors) |

| Thermocouple | Invasive | Low (cm) | High (ms) | No | Poor |

| Infrared Imaging | Non-invasive | Medium (cm) | High (ms) | No | N/A |

| MR Thermometry | Non-invasive | High (mm) | Low (1-4 s) | Yes | N/A |

| Ultrasound Temp. Est. | Non-invasive | Low (cm) | Medium | Yes | N/A |

Visualization: Pathways and Workflows

Diagram Title: FBG Feedback Loop in Thermal Therapy Control System

Diagram Title: Experimental Workflow for FBG Surgical Tool Development

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for FBG-Based Thermal Therapy Research

| Item | Function/Description | Example Specification/Note |

|---|---|---|

| FBG Optical Fiber | Core sensing element. | Germanosilicate, single-mode, polyimide coating for durability. |

| Optical Interrogator | Measures reflected Bragg wavelength shifts with high precision. | 1-5 pm wavelength resolution, >1 kHz sampling rate per channel. |

| Broadband Light Source | Provides optical power for the FBG array. | ASE source (e.g., C-band, 1520-1570 nm). |

| Biocompatible Sheathing | Protects FBG, ensures sterility and patient safety. | Medical-grade polyimide tubing or fluoropolymer catheter. |

| Tissue-Mimicking Phantom | Provides realistic medium for in-vitro testing. | Agar-based with NaCl (conductivity) or polyacrylamide gel. |

| Calibration Equipment | For characterizing KT and Kε. | Precision water bath (±0.1°C), micro-tensile stage. |

| Reference Thermometry | Validates FBG temperature readings. | Fluoroptic probes (MRI-safe) or calibrated thermocouples. |

| Surgical Tool Platform | For sensor integration and testing. | Biopsy needle, RF/Microwave ablation probe, or laparoscopic tool. |

| Data Acquisition Software | For real-time visualization and recording. | Custom LabVIEW or Python suite with decoupling algorithm. |

This whitepaper details the application of Fiber Bragg Grating (FBG) sensors in pharmaceutical development, framed within the broader thesis of FBG sensitivity to strain and temperature in healthcare research. FBGs are intrinsic sensor elements inscribed in optical fibers that reflect specific wavelengths of light. The Bragg wavelength (λB) shift (ΔλB) is linearly dependent on both strain (ε) and temperature change (ΔT), as described by: ΔλB / λB = (1 - pe)ε + (αΛ + αn)ΔT where pe is the photo-elastic coefficient, and αΛ and αn are thermal expansion and thermo-optic coefficients, respectively. This dual sensitivity must be decoupled for precise measurements, a core challenge in the discussed methodologies.

Core Sensing Principles and Sensitivity Decoupling

FBGs respond to physical and chemical changes in their environment. In drug delivery, these changes are transduced into measurable wavelength shifts.

Table 1: FBG Response Coefficients for Standard Silica Fiber

| Parameter | Symbol | Typical Value | Unit |

|---|---|---|---|

| Strain Sensitivity | K_ε | ~1.2 pm/με | pm/microstrain |

| Temperature Sensitivity | K_T | ~10 pm/°C | pm/°C |

| Gauge Factor | GF | ~0.78 | dimensionless |

| Thermo-optic Coefficient | α_n | 8.31 x 10^-6 | /°C |

Decoupling strain and temperature is critical. Common methods include:

- Dual-Grating Method: Using two FBGs with different responses (e.g., one bare, one packaged).

- Reference FBG: Placing a reference FBG in a strain-free, temperature-matched environment.

- FBG in Tension-Free Configuration: Isolating the sensor from mechanical strain.

Diagram Title: FBG Signal Decoupling Workflow for Drug Delivery Sensing

Experimental Applications and Protocols

Monitoring Drug Dissolution and Release Kinetics

Protocol: An FBG is coated with a thin layer of the drug formulation or embedded within a polymeric drug carrier (e.g., a tablet or microsphere). As the coating dissolves or the polymer degrades, the local refractive index (RI) and mechanical strain on the fiber change, inducing a λ_B shift.

- Sensor Preparation: Coat a standard telecom FBG (λB ~1550 nm) with a uniform layer of the drug-polymer matrix using dip-coating or spray coating. Measure initial thickness and λB.

- Calibration: Calibrate the FBG's RI sensitivity in solutions of known index (e.g., glycerol/water mixtures).

- Dissolution Test: Immerse the coated FBG in a dissolution bath (e.g., pH 7.4 PBS at 37°C, 50 rpm). Use an interrogation system to record λ_B at 1 Hz.

- Data Analysis: Correlate Δλ_B with dissolution profiles obtained via traditional UV spectroscopy. The rate of wavelength change correlates with dissolution rate.

Table 2: Sample FBG Dissolution Monitoring Data for a Model Polymer

| Time (min) | Δλ_B (pm) | UV Absorbance (AU) | Coating Thickness (μm) |

|---|---|---|---|

| 0 | 0 | 0.00 | 50.0 ± 2.1 |

| 10 | 45 ± 3 | 0.15 ± 0.02 | 42.5 ± 3.0 |

| 30 | 112 ± 5 | 0.41 ± 0.03 | 28.7 ± 2.5 |

| 60 | 205 ± 8 | 0.78 ± 0.04 | 10.2 ± 1.8 |

| 120 | 288 ± 10 | 0.95 ± 0.01 | 1.5 ± 0.5 |

Measuring Intraluminal Pressure in Swellable Devices

Protocol: FBGs are ideal for measuring small pressure changes in gastrointestinal tract simulators or within expanding drug-eluting stents.

- Sensor Packaging: Encapsulate an FBG in a flexible, fluid-filled capsule or attach it to the interior wall of a swellable hydrogel device. Pressure changes strain the capsule/device, transferring strain to the FBG.

- Pressure Calibration: Place the packaged sensor in a calibrated pressure chamber. Apply known pressures (0-200 mmHg) and record Δλ_B to establish a linear sensitivity coefficient (pm/mmHg).

- In Vitro Testing: Deploy the sensor in a simulated gastric or intestinal environment. Monitor real-time pressure changes as the device swells, erodes, or undergoes peristalsis.

Characterizing Structural Dynamics of Delivery Systems

Protocol: FBG arrays (multiple gratings on one fiber) map strain distribution along implantable scaffolds or microneedles.

- Array Fabrication: Inscribe an array of 5-10 FBGs with 10 mm spacing on a single fiber.

- Integration: Embed the array into a biodegradable polymer scaffold or attach it to the base of a microneedle patch.

- Mechanical Testing: Subject the system to controlled compression, bending, or hydration in a tensile stage. The interrogation system tracks each FBG independently.

- Dynamic Mapping: Generate 2D strain maps over time to identify points of structural failure, uneven swelling, or deformation.

Diagram Title: Unified Experimental Workflow for FBG Drug Delivery Applications

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for FBG-based Drug Delivery Research

| Item | Function & Specification | Example Vendor/Product |

|---|---|---|

| FBG Interrogator | High-resolution (≤1 pm) device to measure λ_B shifts in real-time. Essential for dynamic monitoring. | Micron Optics sm125, FBGS Technologies interrogators, Ibsen Photonics I-MON series. |

| Single-Mode Optical Fiber with FBG Arrays | The core sensor. Arrays allow multipoint sensing. Standard telecom (1550 nm) or custom wavelengths. | FBGS Technologies, TechnicaSA, Oz Optics. |

| Dip-Coater | For applying uniform polymeric or drug-coating layers onto FBGs with controlled thickness. | Nadetech Innovations, KSV Nima. |

| Dissolution Apparatus | USP-compliant bath (e.g., Apparatus 2) for standardized testing under controlled pH, temperature, and agitation. | Distek, Sotax, Agilent. |

| Programmable Pressure Chamber | For calibrating pressure sensitivity of packaged FBG sensors. | Ellab, STL. |

| Biocompatible Polymer Coatings | Hydrogels (e.g., HPMC, PVA) or biodegradable polymers (PLGA, PCL) to functionalize FBGs for specific applications. | Sigma-Aldrich, Lakeshore Biomaterials. |

| Refractive Index Calibration Kits | Pre-mixed solutions of known RI (e.g., sucrose, glycerol) for sensor calibration. | Cargille Labs, Mettler Toledo. |

| Temperature-Controlled Stage/Chamber | For precise thermal management and decoupling experiments. | Linkam, Instec. |

Table 4: Performance Comparison of FBG Sensing Modalities in Drug Delivery

| Sensing Modality | Measurand | Typical Δλ_B Range | Resolution | Key Advantage | Primary Challenge |

|---|---|---|---|---|---|

| Dissolution (RI-Based) | Coating Thickness / RI Change | 100 - 2000 pm | ~5 pm | Real-time, label-free kinetics. | Decoupling RI from temperature effects. |

| Intraluminal Pressure | Hydrostatic Pressure (e.g., in GI tract) | 50 - 500 pm (per 50 mmHg) | <1 pm | Miniature, biocompatible, high sensitivity. | Packaging integrity and hysteresis. |

| Structural Strain (Scaffold) | Microstrain (με) | 1.2 pm/με | ±1 με | Multipoint mapping on a single fiber. | Complex integration without structural compromise. |

| Temperature (Reference) | Temperature Change (°C) | 10 pm/°C | ±0.1 °C | Accurate thermal monitoring for decoupling. | Requires isolation from mechanical strain. |